Abstract

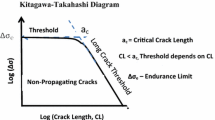

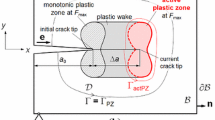

Kitagawa-Takahashi diagram combines the endurance limit of a smooth specimen and the crack propagation threshold in a fracture mechanics specimen into single diagram thus providing the connection between the stress or strain-life and damage tolerance approaches. The diagram is modified by considering that (a) fatigue requires two independent load-parameters for unambiguous description, (b) long crack growth behavior defines the material resistance under constant stress amplitudes along with the associated R-ratio effects, (c) remote applied stresses and localized plasticity-effects can be combined to provide the total mechanical force opposing the material resistance leading to crack initiation, growth and failure describable in the diagram, (d) localized plasticity contributes to internal stresses that either augment or retard the remote stresses, and finally (e) the magnitude and gradient of these internal stresses determine the condition for propagation and/or non-propagation of the incipient cracks that form either at pre-existing stress concentrations or in situ formed stress concentrations due to localized plasticity. Localized plasticity forms the basis for the additional crack tip driving forces in either accelerating or decelerating crack growth kinetics thereby providing conditions for either crack arrest with resulting non-propagating cracks or for continuous uninterrupted crack growth. Internal stresses are generated during fatigue damage in the form of dislocation pile-ups, intrusions and extrusions. The analysis shows that critical magnitude and gradient of the internal stresses are required for an incipient crack to grow continuously, failing which crack arrest can occur. The methodology is based on separating the mechanically introduced crack tip driving forces vs the material resistance; the later can be extracted from long-crack growth data under constant amplitudes. Analysis of incipient short cracks growing under the elastic-plastic notch tip stress fields are analyzed systematically for various elastic stress concentrations, K t, and notch-tip radii, ρ. A general formulation is developed based on the calculations that can be incorporated into the unified life predication model that is being developed.

Similar content being viewed by others

References

SAE Fatigue Design Approach, 3rd ed., SAE International, Warrendale, PA, 1997.

Damage Tolerant Design DTD Handbook, The DOD Joint Service Specification Guide—JSSG-2006—Aircraft Structures.

“Fatigue, Fail-Safe, and Damage Tolerance Evaluation of Metallic Structure for Normal, Utility, Acrobatic, and Commuter Category Airplanes”, AC 23-13A, FAA, US Department of Transportation, September 29, 2005.

H. Kitagawa and S. Takahashi: in Proceedings of the Second International Conference on Mechanical Behavior of Materials, ASM, Metals Park, OH, 1976, vol. 956, pp. 627–31.

A.K. Vasudevan and K. Sadananda: Mater. Sci. Eng., 1994, vol. A188, pp. 1–22.

A.K. Vasudevan and K. Sadananda: Metall. Mater. Trans., 1995, vol. 26A, pp. 1221–34.

K. Sadananda and A.K. Vasudevan: Int. J. Fatigue, 1997, vol. 19, pp. S99–S109.

K. Sadananda and A.K. Vasudevan: Int. J. Fatigue, 2003, vol. 25, pp. 899–914.

J. Goodman: Mechanics Applied to Engineering, Longmans Green, London, 1899, p. 934.

N.E. Dowling: Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture and Fatigue, 2nd ed., Prentice Hall, Upper Saddle River, NJ, 1999.

R.G. Forman, V.E. Kearney, and R.M. Engle: J. Basic Eng., 1987, vol. 89, pp. 459–64.

P.C. Paris and F. Erdogan: Trans. ASME J. Basic Eng., 1963, vol. 85, pp. 528–34.

S. Suresh and R. Ritchie: Int. Met. Rev., 1984, vol. 29, pp. 445–76.

N. Lout, K. Sadananda, M. Duesbery, and A.K. Vasudevan: Metall. Trans. A, 1993, vol. 24A, pp. 2225–32.

A.K. Vasudevan: “Unified Fatigue Damage Analysis: The Uni-Grow Model”, ONR-Briefing for the Condition-Based Maintenance Plus Action Group, March 2, 2011.

J. Lagrange: Méchanique Analytique, IVth ed., Gauthier-Villars, Paris, 1788, p. 226.

K. Sadananda, S. Sarkar, D. Kujawski, and A.K. Vasudevan: Int. J. Fatigue, 2009, vol. 31, pp. 1648–59.

K. Sadananda, A.K. Vasudevan, and N. Phan: Int. J. fatigue, 2007, vol. 29, pp. 2060–71.

M.H. El-Haddad, T.H. Topper, and K.N. Smith: Eng. Fract. Mech., 1979, vol. 11, pp. 573–84.

K. Tanaka, Y. Nakai, and M. Yamashita: Int. J. Fatigue, 1981, vol. 17, pp. 519–33.

R. Pippan, M. Berger, and H.P. Stüwe: Metall. Trans., 1987, vol. 18A, p. 429.

A. Pineau: Short Fatigue Crack Behavior in Relation to Three-Dimensional Aspects and Crack Closure Effect, in Proceedings: Small Fatigue Cracks, R.O. Ritchie and J. Lankford, eds., AIME, 1986, pp. 191–212.

D.O. Sprowls, M.B. Shumaker, J.D. Walsh, and J.W. Coursen: “Evaluation of Stress Corrosion Cracking Susceptibility Using Fracture Mechanics Techniques”, Final Report of Govt. Contract, NAS 8-21487, Part I, May 31, 1973.

A. Navarro and E.R. de los Rios: Philos. Mag, 1988, vol. 57, pp. 15–36.

M.S. Bruzzi and P.E. McHugh: Int. J. Fatigue, 2002, vol. 24, pp. 1071–78.

K. Tanaka and T. Mura: Acta Metall., 1984, vol. 32, pp. 1731–40.

I.R. Kramer: Metall. Trans., 1974, vol. 5, p. 1735.

D. Taylor: Fatigue Fract. Eng. Mater. Struct., 2001, vol. 24, pp. 215–24.

S. Usami: in Small Fatigue Cracks, R.O. Ritchie and J. Lankford, eds., AIME, Warrendale, PA, 1986, pp. 559–86.

E. Orowan: Fracture and Strength of Solids. Reports on Progress in Physics XII, 1948, pp. 185–232.

G.R. Irwin: J. Appl. Mech., 1957, vol. 24, pp. 361–64.

J.R. Rice: An Examination of the Fracture Mechanics Energy Balance from the Point of View of Continuum Mechanics, in Proc. 1st Inter. Con. Fracture, Sendai, 1965, T. Yokobori, T. Kawasaki, and J. L. Swedlow, eds., vol. 1, Japanese Society for Strength and Fracture of Materials, Tokyo, 1966, pp. 309–40.

N.E. Fleck, C.S. Shin, and R.A. Smith: Eng. Fract. Mech., 1985, vol. 21, pp. 173–85.

S. Suresh: Eng. Fract. Mech., 1985, vol. 21, pp. 452–63.

R. Pippan: Fatigue Fract. Eng. Mater. Struct., 1987, vol. 9, pp. 319–28.

J.C. Newman, Jr. and Y. Yamada: Int. J. Fatigue, 2010, vol. 32, pp. 879–85.

S. Suresh: Fatigue of Materials, 2nd ed., Cambridge University Press, Cambridge, 1998.

D. Kujawski: Eng. Fract. Mech., 2008, vol. 75, pp. 5246–47.

J.C. Newman, Jr.: Private Communication, 2009.

G. Shen and G. Glinka: Theor. Appl. Fract. Mech., 1991, vol. 15, pp. 247–55.

Air Force Report: “Improved High Cycle Fatigue (HCF) Life Prediction”, UDRI Industry Team, UDR-TR-1999-00079, 2001.

J.B. Barson and R.C. McNicol: “Effect of Stress Concentration on Fatigue-Crack Initiation in HY-130 Steel”, ASTM-STP # 559, 1973, pp. 183–204.

M. Creager and P.C. Paris: Eng. Fract. Mech., 1967, vol. 3, pp. 247–52.

K. Endo, K. Komai, and I. Yamamoto: Bull. MSME, 1981, vol. 24, pp. 1326–32.

Acknowledgments

The research is supported by ONR under the contract N00014-10c-0359 with Dr. Vasudevan as Technical Monitor. The authors acknowledge stimulating discussions with Drs. A.K. Vasudevan, Nagaraja Iyyer, Professors D. Kujawski and G. Glinka.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 25, 2012.

Rights and permissions

About this article

Cite this article

Sadananda, K., Sarkar, S. Modified Kitagawa Diagram and Transition from Crack Nucleation to Crack Propagation. Metall Mater Trans A 44, 1175–1189 (2013). https://doi.org/10.1007/s11661-012-1416-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1416-x