Abstract

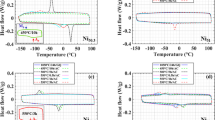

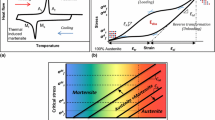

Over the past decade, interest in shape-memory-alloy based actuators has increased as the primary benefits of these solid-state devices have become more apparent. However, much is still unknown about the characteristic behavior of these materials when used in actuator applications. Recently, we showed that the maximum temperature reached during thermal cycling under isobaric conditions could significantly affect the observed mechanical response of NiTi (55 wt pct Ni), especially the amount of transformation strain available for actuation and thus work output. The investigation we report here extends that original work to (1) ascertain whether increases in the upper-cycle temperature would produce additional changes in the work output of the material, which has a stress-free austenite finish temperature of 386 K (113 °C), and (2) determine the optimum cyclic conditions. Thus, isobaric, thermal-cycle experiments were conducted on the aforementioned alloy at various stresses from 50 to 300 MPa using upper-cycle temperatures of 438 K, 473 K, 503 K, 533 K, 563 K, 593 K, and 623 K (165 °C, 200 °C, 230 °C, 260 °C, 290 °C, 320 °C, and 350 °C). The data indicated that the amount of applied stress influenced the transformation strain, as would be expected. However, the maximum temperature reached during the thermal excursion also plays an equally significant role in determining the transformation strain, with the maximum transformation strain observed during thermal cycling to 563 K (290 °C). In situ neutron diffraction at stress and temperature showed that the differences in transformation strain were mostly related to changes in martensite texture when cycling to different upper-cycle temperatures. Hence, understanding this effect is important to optimizing the operation of SMA-based actuators and could lead to new methods for processing and training shape-memory alloys for optimal performance.

Similar content being viewed by others

References

X.D. Wu, G.J. Sun, and J.S. Wu: Mater. Lett., 2003, vol. 57, pp. 1334–38.

B. Ye, B.S. Majumdar, and I. Dutta: Acta Mater., 2009, vol. 57, pp. 2403–17.

J.H. Mabe, R. Ruggeri, and F.T. Calkins: Proc. International Conference on Shape Memory and Superelastic Technologies (SMST), 2006, pp. 629–44.

G.S. Bigelow, R.D. Noebe, S.A. Padula, and A. Garg: Proc. International Conference on Shape Memory and Superelastic Technologies (SMST), 2006, pp. 113–31.

R.D. Noebe, S.L. Draper, D.J. Gaydosh, A. Garg, B. Lerch, N. Penney, G.S. Bigelow, and S.A. Padula: Proc. International Conference on Shape Memory and Superelastic Technologies (SMST), 2006, pp. 409–26.

L.L. Toia, A. Coda, G. Vergani, L. Fumagalli, and F. Butera: Proc. Int. Conf. on Shape Memory and Superelastic Technologies (SMST), 2006, pp. 499–506.

H. Warlimont, L. Delaey, R.V. Krisknan, and H. Tas: J. Mater. Sci., 1974, vol. 9, pp. 1545–55.

K.N. Melton and O. Mercier: Acta Metall., 1981, vol. 29, pp. 393–98.

A. Stebner, S. Padula II, R. Noebe, B. Lerch, and D. Quinn: J. Intell. Mater. Syst. Struct., 2009, vol. 20, pp. 2107–26.

S.A. Padula II, D.J. Gaydosh, R.D. Noebe, G.S. Bigelow, A. Garg, D. Lagoudas, I. Karaman, and K.C. Atli: Behavior and Mechanics of Multifunctional and Composite Materials II, SPIE Conf. Proc., 2008, vol. 6929, pp. 692912-1–11.

M.A.M. Bourke, D.C. Dunand, and E. Ustundag: Appl. Phys. A, 2002, vol. 74, p. S1707.

R. Vaidyanathan, M.A.M. Bourke, and D.C. Dunand: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 777–86.

S. Qiu, V.B. Krishnan, S.A. Padula II, R.D. Noebe, D.W. Brown, B. Clausen, and R. Vaidyanathan: Appl. Phys. Lett., 2009, vol. 95, p. 141906.

S. Rajagopalan, A.L. Little, M.A.M. Bourke, and R. Vaidyanathan: Appl. Phys. Lett., 2005, vol. 86, p. 081901.

D.C. Dunand, D. Mari, M.A.M Bourke, and J.A. Roberts: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2820–36.

S. Qiu, S.A. Padula II, R.D. Noebe, D.W. Brown, and R. Vaidyanathan: Metall. Mater. Trans. A, in press.

E.C. Oliver, N. Kobayashi, T. Mori, M.R. Daymond, and P.J. Withers: Scripta Mater., 2003, vol. 49, pp. 1013–19.

M.A.M. Bourke, R. Vaidyanathan, and D.C. Dunand: Appl. Phys. Lett., 1996, vol. 69, pp. 2477–79.

R. Vaidyanathan, M.A.M. Bourke, and D.C. Dunand: J. Appl. Phys., 1999, vol. 86, pp. 3020–29.

S. Qiu, S.A. Padula II, R.D. Noebe, and R. Vaidyanathan: Acta Mater., in press.

Acknowledgments

This work was supported by the Fundamental Aeronautics Program, Supersonics Project, API: Dale Hopkins. The authors thank B. Clausen, D. Brown, and T. Sisneros at Los Alamos National Laboratory for experimental assistance. This work has benefited from the use of the Lujan Neutron Scattering Center at LANSCE, which is funded by the Office of Basic Energy Sciences (DOE). LANL is operated by Los Alamos National Security LLC under DOE Contract DE-AC52-06NA25396.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 25, 2010.

Rights and permissions

About this article

Cite this article

Padula, S., Qiu, S., Gaydosh, D. et al. Effect of Upper-Cycle Temperature on the Load-Biased, Strain-Temperature Response of NiTi. Metall Mater Trans A 43, 4610–4621 (2012). https://doi.org/10.1007/s11661-012-1267-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1267-5