Abstract

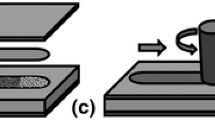

A new friction powder compaction (FPC) process by the sintering and dissolution process (SDP) route for fabricating open-cell aluminum (Al) foam, which requires no external heat sources, was developed. Foams with porosities of 74 and 83 pct were successfully fabricated and their compressive responses were investigated. The sintered mixture during the removal process was observed nondestructively by X-ray computed tomography (CT) to reveal the progress of the removal of soluble particles and to confirm that they were completely dissolved.

Similar content being viewed by others

References

J. Banhart: Prog. Mater. Sci., 2001, vol. 46, pp. 559–632.

Y.Y. Zhao and D.X. Sun: Scripta Mater., 2001, vol. 44, pp. 105–10.

D.X. Sun and Y.Y. Zhao: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 69–74.

C.E. Wen, M. Mabuchi, Y. Yamada, K. Shimojima, Y. Chino, H. Hosokawa, and T. Asahina: J. Mater. Sci. Lett., 2003, vol. 22, pp. 1407–09.

Y.Y. Zhao, F.S. Han, and T. Fung: Mater. Sci. Eng. A, 2004, vol. 364, pp. 117–25.

D.X. Sun and Y. Zhao: Mater. Lett., 2005, vol. 59, pp. 6–10.

M. Hakamada, Y. Yamada, T. Nomura, Y.Q. Chen, H. Kusuda, and M. Mabuchi: Mater. Trans., 2005, vol. 46, pp. 2624–28.

M. Hakamada, T. Kuromura, Y.P. Chen, H. Kusuda, and M. Mabuchi: Appl. Phys. Lett., 2006, vol. 88, p. 254106.

M. Hakamada, T. Kuromura, Y. Chino, Y. Yamada, Y.Q. Chen, H. Kusuda, and M. Mabuchi: Mater. Sci. Eng. A, 2007, vol. 459, pp. 286–93.

R. Surace, L.A.C. De Filippis, A.D. Ludovico, and G. Boghetich: Mater. Des., 2009, vol. 30, pp. 1878–85.

B. Jiang, N.Q. Zhao, C.S. Shi, and J.J. Li: Scripta Mater., 2005, vol. 53, pp. 781–85.

B. Jiang, Z.J. Wang, and N.Q. Zhao: Scripta Mater., 2007, vol. 56, pp. 169–72.

N. Michailidis, F. Stergioudi, and D.N. Tsipas: Adv. Eng. Mater., 2011, vol. 13, pp. 29–32.

N. Michailidis, F. Stergioudi, A. Tsouknidas, and E. Pavlidou: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1662–67.

A.E. Markaki and T.W. Clyne: Acta Mater., 2001, vol. 49, pp. 1677–86.

Y. Hangai, K. Takahashi, T. Utsunomiya, S. Kitahara, O. Kuwazuru, and N. Yoshikawa: Mater. Sci. Eng. A. DOI:10.1016/j.msea.2011.11.100.

This work was partly financially supported by the Industrial Technology Research Grant Program in 2009 from the New Energy and Industrial Technology Development Organization (NEDO) of Japan. The authors thank Professor K. Saito, Gunma University, for his helpful advice on conducting the experiments and Mitachi Applied Engineering Co., Ltd. for their help conducting experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 30, 2011.

Rights and permissions

About this article

Cite this article

Hangai, Y., Yoshida, H. & Yoshikawa, N. Friction Powder Compaction for Fabrication of Open-Cell Aluminum Foam by the Sintering and Dissolution Process Route. Metall Mater Trans A 43, 802–805 (2012). https://doi.org/10.1007/s11661-011-1073-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-1073-5