Abstract

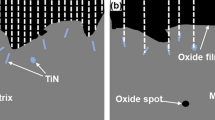

Surface scale occurs on the external surface of directionally solidified, single-crystal turbine components. It is one of the most important casting defects because it affects the grain orientation assessment and causes incipient surface melting during heat treatment. The formation of surface scale comprises a three-stage process: (1) formation of a 0.5- to 1.5-μm Al2O3 layer around the external surface of liquid metal as a result of the mold/metal reaction between the liquid and the mold prime coat; (2) separation of the solidified metal from the mold wall during cooling, where the Al2O3 layer is stripped away from the metal surface but remains adhered to the mold; and (3) subsequent oxidation of the “bare” metal to form an oxide scale at the surface. The scale comprises a mixture of oxides. It is found that TiO2, Cr2O3, and Al2O3 form on components cast using the 1st generation alloy, SRR99; however, in the case of castings using the 3rd-generation alloy, CMSX10N it is a predominately nickel-rich oxide (likely to be NiO). On the unscaled surface, the mold and metal are in intimate contact during casting, and subsequent cooling and the Al2O3 layer around the external surface prevents subsequent oxidation of the casting surface.

Similar content being viewed by others

References

R.C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, UK, 2006.

A. Heckl, R. Rettig, and R.F. Singer: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 202–11.

J.S. Van Sluytman, A. La Fontaine, and J.M. Cairney: Acta Mater., 2010, vol. 58, pp. 1952–62.

B.C. Wilson and G.E. Fuchs: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1235–45.

J. Valdes, S.L. Shang, Z.K. Liu, P. King, and X.B. Liu: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 487–98.

N. Tsuno, K. Kakehi, C.M.F. Ray, and R. Hashizumme: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 269–72.

A.J. Heidoloff, J. Van Sluytman, T.M. Pollock, and B. Gleeson: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 1529–40.

N. D’Souza, R. Beanland, C. Hayward, and H.B. Dong: Acta Mater., 2011, vol. 59, pp. 1003–13.

Z.K. Chu, J.J. Yu, X.F. Sun, H.R. Guan, and Z.Q. Hu: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2927–37.

G. Brewster, H.B. Dong, N.R. Green, and N. D’Souza: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 87–93.

H.T. Pang, H.B. Dong, R. Beanland, H.J. Stone, C.M.F. Rae, P.A. Midgley, G. Brewster, and N. D’Souza: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 1660–69.

H.J. Dai, N. D’Souza, and H.B. Dong: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3430–38.

H.J. Dai, H.B. Dong, N. D’Souza, C.-J. Gebelin, and R.C. Reed: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3439–46.

D.L. Anton and A.F. Giamei: Metall. Trans. A, 1985, vol. 16, pp. 1997–2005.

F.L. Versynder and M.E. Shank: Mater. Sci. Eng., 1970, vol. 6, pp. 213–47.

J.R. Mihalisin, J. Corrigan, M.G. Launsbach, E.L. Leonard, R.J. Baker, and B. Griffin: Proc. 10th International Symposium on Superalloys, Champion, PA, 2004, pp. 795–800.

H. Frye, M. Yasrebi, and D.H. Sturgis: Proc. 24th Annual Santa Fe Symposium, Albuquerque, NM, 2000, pp. 1–17.

N. Iman, S. Jones, and P.M. Marquis: 24th BICTA Conference on Investment Casting, Oxford, UK, 1999, pp. 1–8.

R.C. Feagin: Proc. 6th World Conference on Investment Casting, Washington, DC, 1984, pp. 401–13.

C. Cingi: Ph.D. Dissertation, Helsinki University of Technology, Espoo, Finland, 2006.

M.F.X. Gigliotti and C. Greskovich: Metall. Trans. A, 1980, vol. 11A, pp. 319–22.

S. Jones and P.M. Marquis: Proc. 45th Investment Casting Institute Annual Technical Meeting and Exhibition, Atlanta, GA, 1997, pp. 17–19.

T.S. Piwonka: Proc. 42nd Investment Casting Institute Annual Technical Meeting and Exhibition, Atlanta, GA, 1994, pp. 40–52.

B.P. Bewlay, L. Cretegny, M. Gigliotti, R.J. Petterson, A.M. Ritter, and S.F. Rutkowski: U.S. Patent Publication No. US 7296616 B2, 2007.

S.C. Huang, A.J. Elliott, M. Gigliotti, R.J. Petterson, and S.F. Rutkowski: U.S. Patent Publication No. US 2010/0170654 A1, 2010.

S.C. Huang, S.F. Rutkowski, M. Gigliotti, and R.J. Petterson: U.S. Patent Publication No. US 2010/0304161 A1, 2010.

M. Gigliotti. S.F. Rutkowski, S.C. Huang, R.J. Petterson, L.E. Iorio, and A.J. Elliott: U.S. Patent Publication No. US US20090314390, 2009.

VeriCAST Dissemination Report, Rolls-Royce plc, Internal Communication, November 1996

L. Huang, X.F. Sun, H.R. Guan, and Z.Q. Hu: Tribol. Lett., 2006, vol. 23, pp. 15–22.

M. Hook: Ph.D. Dissertation, University of Cambridge, Cambridge, UK, 2004.

A. Akhtar, S. Hegde, and R.C. Reed: JOM, 2006, vol. 58, pp. 37–42.

C.M. Younes, G.C. Allen, and J.A. Nicholson: Corros. Eng. Sci. Technol., 2007, vol. 42, pp. 80–88.

F.D. Richardson and J.H.E. Jeffes: J. Iron Steel Inst., 1948, vol. 160, pp. 261–70.

Acknowledgments

The authors would like to thank the STFC for access to XPS facility at NCESS, Daresbury Laboratory (RG679 and RG670) and Dr. Gary Critchlow at Department of Materials, University of Loughborough. K.S.R. wishes to thank the Royal Society for funding under the Industry Fellowship scheme (grant IF090090).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 12, 2011.

Rights and permissions

About this article

Cite this article

Brewster, G., D’Souza, N., Ryder, K.S. et al. Mechanism for Formation of Surface Scale during Directional Solidification of Ni-Base Superalloys. Metall Mater Trans A 43, 1288–1302 (2012). https://doi.org/10.1007/s11661-011-1027-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-1027-y