Abstract

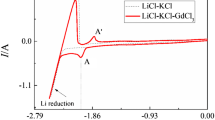

In order to remove impurity AlCl3 from LiCl-KCl melts before Li electrolysis, the Al3+ reduction potential on a tungsten electrode and the relation between Al3+ reduction peak current and AlCl3 concentration in LiCl-KCl-AlCl3 melts were determined by cyclic voltammetry (CV). Constant potential electrolysis at –1.6 V vs Cl2/Cl– on both solid Fe and liquid Zn cathodes was performed to remove AlCl3 impurity from the LiCl-KCl-AlCl3 melts. The removal rate of Al3+ from the melts was analyzed by both electrochemical methods and inductively coupled plasma–atomic emission spectrometry (ICP-AES) analysis. The results showed that 96.11 wt pct of Al were removed on a Fe cathode and 99.90 wt pct on a Zn cathode through 10 hours electrolysis, respectively. While stirring the melts by argon gas, 99.21 wt pct of Al3+ was separated from the melts by 4 hours of electrolysis at 723 K (450 °C), which effectively expedited the Al3+ electrochemical reduction rate and shortened the electrolysis time.

Similar content being viewed by others

References

W.A. Averill and D.L. Olson: Int. J. Energy Res., 1978, vol. 3 (3), pp. 305–13.

P.A. Mahi, A.J. Smeets, D.J. Fray, and J.A. Charles: J. Met., 1986, vol. 38 (11), pp. 20–26.

W.E. Cowley: Molten Salt Technology, D.G. Lovering, ed., Plenum Press, New York, NY, 1982, pp. 215–18.

P.E. Landolt: Rare Metals Handbook, C.A. Hampel Reinhold Press, New York, NY, 1954, pp. 136–38.

C.L. Mantel: Electrochemical Engineering, McGraw-Hill Press, New York, NY, 1960, pp. 56–59.

G.T. Motock: Electrochem. Technol., 1963, vol. 1, pp. 122–28.

S. Shen: Molten Salts Electrochemical Theory Foundation, China Industrial Press, Beijing, 1963, pp. 98–102.

W.L. Chen, L.Y. Chai, X.B. Min, B. Yang, Y.N. Dai, X. Yu, and C.F. Zhang: Trans. Nonferrous Met. Soc. China, 2002, vol. 1, pp. 152–55.

W.L. Chen, L.Y. Chai, X.B. Min, B. Yang, Y.N. Dai, X. Yu, and C.F. Zhang: Trans. Nonferrous Met. Soc. China, 2001, vol. 6, pp. 937–41.

H. Lan: Xinjiang Youse Jinshu, 1996, vol. 8, pp. 55–57.

T.P. Lou, D.G. Li, R. Pan, and H.P. Zhang: Acta Phys. Chim. Sinica, 2003, vol. 19, pp. 839–43.

J. Gulens, B.W. Hildebrandt, J.D. Canaday, A.K. Kuriakose, T.A. Weat, and A. Ahmad: Solid State Ionics, 1989, vol. 35 (1–2), pp. 45–49.

Z.N. Jin, X.M. Li, W.J. Lan, and X.R. Liu: J. Northeast. Univ. (Nat. Sci.), 2006, vol. 27 (11), pp. 1251–54.

Y.D. Yan, M.L. Zhang, Y.X.W. Han, D.X. Cao, and L.Y. He: J. Appl. Electrochem., 2009, vol. 39, pp. 455–46.

J. Bouteillon and A. Marguier: Surf. Coat. Technol., 1984, vol. 22 (3), pp. 205–17.

M. Gabčo, P. Fellner, and Ž. Lubyová: Electrochim. Acta, 1984, vol. 29 (3), pp. 397–401.

Y.J. Zhang, A. Bjørgum, U. Erikson, R. Tunold, and R. Ødegård: J. Electroanal. Chem. Interface, 1986, vol. 210 (1), pp. 127–36.

X. Qi and H.M. Zhu: Basic Study of Electrochemical Co-Deposition of Mg-Al Alloy in Alkali Chloride Melt, University of Science and Technology Beijing Press, Beijing, 2004, pp. 26–27.

Q.Q. Yang, B.L. Fang, and Y.X. Tong: J. Appl. Electrochem., 2nd ed., Zhongshan University Press, Guangzhou, 2005, pp. 49–55.

T. Berzins and P. Delahay: J. Am. Chem. Soc., 1953, vol. 75 (3), pp. 555–59.

R. Ødegard, A. Bjørgum, A. Sterten, J. Thonstad, and R. Tunold: Electrochim. Acta, 1982, vol. 27 (11), pp. 1595–98.

R.P. Elliot: Phase Diagram, McGraw-Hill Press, New York, NY, 1965, pp. 381–88.

J.Q. Yu, W.Z. Yi, B.D. Chen, and H.J. Chen: Binary Alloy Phase-Diagrams, Shanghai Science and Technology Press, Shanghai, 1983, pp. 140–63.

A.E. Herrera-Erazo, H. Habazaki, K. Shimizu, P. Skeldon, and G.E. Thompson: Corros. Sci., 2000, vol. 42 (10), pp. 1823–30.

M. Jafarian, F. Forouzandeh, I. Danaee, F. Gobal, and M.G. Mahjani: J. Solid State Electrochem., 2009, vol. 13 (8), pp. 1171–79.

Z.X. Qiu: Principle and Application of Aluminum Electrolysis, Chinese Mining Industrial University Press, Suzhou, 1998, pp. 567–689.

Acknowledgments

This work was financially supported by the 863 projects of the Ministry of Science and Technology of China (Grant No. 2009AA06Z102), the Key Program of the National Natural Science Foundation (Grant No. 50934001), and the National Natural Science Foundation (Grant No. 51054004); we also appreciate the support of the Key Laboratory of Chemical Engineering, Ministry of Education.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 5, 2010.

Rights and permissions

About this article

Cite this article

Shen, M., Li, B., Li, S.Z. et al. Electrochemical Removal of AlCl3 from LiCl-KCl Melts. Metall Mater Trans A 43, 1662–1669 (2012). https://doi.org/10.1007/s11661-011-0982-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0982-7