Abstract

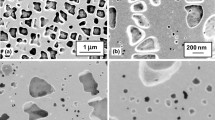

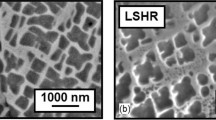

Single crystals of a nickel-base superalloy were directionally solidified (DS) over a range of cooling rates to evaluate the benefits of a new high thermal gradient solidification process. Solidification experiments were conducted on cylindrical bars with a liquid-metal-enhanced cooling process. This higher gradient casting process was evaluated for the degree of structure refinement, microstructural variability, and porosity distributions. Cylindrical bars of 1.6-cm diameter were solidified at rates between 8.4 and 21.2 mm/min using a tin-based, liquid metal cooling (LMC) technique and at a rate of 3.4 mm/min with a conventional Bridgman process. The LMC process produced a refined microstructure with average primary dendrite arm spacing (PDAS) and secondary dendrite arm spacing (SDAS) values as low as 164 and 25 μm, respectively, for the bar geometry evaluated. An optimum intermediate withdrawal velocity of 12.7 mm/min produced up to a 50 and 60 pct refinement in PDAS and SDAS, respectively. Further increases in withdrawal velocity produced smaller SDAS and pore sizes, but undesirable grain boundaries and excessive secondary dendrite arm growth. Voronoi tessellation methods were used to examine the extremes of the dendrite arm spacings in comparison to the average measurements, the packing of dendrites, and the correlation of porosity size and location with the dendrite structure. A simple expression for prediction of the maximum pore size is developed.

Similar content being viewed by others

Notes

RENÉ is a trademark of the General Electric Company, Fairfield, CT.

References

T.M. Pollock and S. Tin: J. Prop. Power, 2006, vol. 22, pp. 361–74.

R.C. Reed: in The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, 2006, pp. 121–87.

M. Gell, C.P. Sullivan, and F.L Ver Snyder: in Solidification Technology, J.J. Burke, M.C. Flemings, and A.E. Gorum, eds., Brook Hill, Chestnut Hill, MA, 1974, pp. 141–64.

M. Konter, E. Kats, and N. Hofmann: in Superalloys 2000, T.M. Pollock, R.D. Kissinger, R.R. Bowman, K.A. Green, M. McLean, S.L. Olson, and J.J. Schirra, eds., TMS, Warrendale, PA, 2000, pp. 189–200.

L. Liu, T.W. Huang, J. Zhang, and H.Z. Fu: Mater. Lett., 2007, vol. 61, pp. 227–30.

F. Hugo, U. Betz, J. Ren, S.-C. Huang, J.A. Bondarenko, and V. Gerasimov: Int. Symp. on Liquid Metal Processing and Casting, A. Mitchell, L. Ridgway, and M. Baldwin, eds., AVS, New York, NY, 1999, pp. 16–30.

A.J. Elliott and T.M. Pollock: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 871–82.

A.J. Elliott, S. Tin, W.T. King, S.-C. Huang, M.F.X. Gigliotti, and T.M. Pollock: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3221–31.

J.G. Tschinkel, A.F. Giamei, and B.H. Kearn: U.S. Patent No. 3,763,926, 1973.

T.J. Fitzgerald and R.F. Singer: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1377–83.

D.G. McCartney and J.D. Hunt: Acta Metall., 1981, vol. 29, pp. 1851–63.

R.E. Spear and G.R. Gardner: AFS, 1963, vol. 71, pp. 209–15.

M. Karavelas: in CGAL User and Reference Manual, 3.3 ed., CGAL Editorial Board, ed., 2007. Available from: http://www.cgal.org.

The MathWorks Inc., Natick, MA.

W.S. Rasband: ImageJ, US National Institutes of Health, Bethesda, MA, 1997–2007, available from: http://rsb.info.nih.gov/ij/.

Y. Murakami and M. Endo: Int. J. Fatigue, 1994, vol. 16, pp. 163–82.

C. Brundidge, J.D. Miller, and T.M. Pollock: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 2723–32.

W. Wang, P.D. Lee, and M. Mclean: Acta Mater., 2003, vol. 51, pp. 2971–87.

D. Ma: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 223–33.

D.R. Poirier, K. Yeum, and A. Maples: Metall. Mater. Trans. A, 1987, vol. 18A, pp. 1979–87.

H.W. Whitesell and R.A. Overfelt: Mater. Sci. Eng. A, 2001, vol. A318, pp. 264–76.

J. Madison, J. Spowart, D. Rowenhorst, L.K. Aagesen, K. Thornton, and T.M. Pollock: Acta Mater., 2010, vol. 58, pp. 2864–75.

J.C. Heinrich and D.R. Poirier: C.R. Mecanique, 2004, vol. 332, pp. 429–45.

Acknowledgments

The authors acknowledge the assistance of C.J. Torbet. The funding provided by General Electric Aviation (GE-USA Program) is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 17, 2011.

Rights and permissions

About this article

Cite this article

Brundidge, C.L., van Drasek, D., Wang, B. et al. Structure Refinement by a Liquid Metal Cooling Solidification Process for Single-Crystal Nickel-Base Superalloys. Metall Mater Trans A 43, 965–976 (2012). https://doi.org/10.1007/s11661-011-0920-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0920-8