Abstract

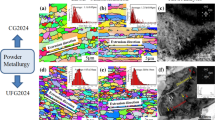

Aluminum alloys with nanocrystalline (NC) and ultrafine grain (UFG) size are of interest because of their strengths that are typically 30 pct greater than conventionally processed alloys of the same composition. In this study, UFG AA 5083 plate was prepared by quasi-isostatic (QI) forging of cryomilled powder, and the microstructure and mechanical behavior was investigated and compared with the behavior of coarse-grained AA 5083. Forging parameters were adjusted in an effort to strengthen the UFG material while retaining some tensile ductility. Different forging parameters were employed on three plates, with approximate dimensions of 254 mm diameter and 19 mm thickness. The overarching goal of the current effort was to increase strength through minimized grain growth during processing while maintaining ductility by breaking up prior particle boundaries (PPBs) with high forging pressures. Mechanical tests revealed that strength increased inversely with grain size, whereas ductility for some of the experimental materials was preserved at the level of the conventional alloy. The application of the Hall-Petch relationship to the materials was studied and is discussed in detail with consideration given to strengthening mechanisms other than grain size, including dispersion (Orowan), solid solution, and dislocation strengthening.

Similar content being viewed by others

References

Z.H. Zhang, B.Q. Han, K.H. Chung, and E.J. Lavernia: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2265-73.

D.B. Witkin and E.J. Lavernia: Progr. Mater. Sci., 2006, vol. 51, no. 1, pp. 1-60.

F.A. Mohamed: Acta Mater., 2003, vol. 51, no. 14, pp. 4107-19.

D. Witkin, B.Q. Han, and E.J. Lavernia: J. Mater. Res., 2005, vol. 20, no. 8, pp. 2117-26.

A.P. Newbery, S.R. Nutt, and E.J. Lavernia: JOM, 2006, vol. 58, no. 4, pp. 56-61.

Y. Li, W. Liu, V. Ortalan, W.F. Li, Z. Zhang, R. Vogt, N.D. Browning, E.J. Lavernia, and J.M. Schoenung: Acta Mater., 2010, vol. 58, no. 5, pp. 1732-40.

T.J. Van Daam and C. Clifford: US Patent 7344675, The Boeing Company, Chicago, IL.

A.P. Newbery, B. Ahn, T.D. Topping, P.S. Pao, S.R. Nutt, and E.J. Lavernia: J. Mater. Process. Tech., 2008, vol. 203, nos. 1–3, pp. 37-45.

D. Witkin, B.Q. Han, and E.J. Lavernia: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 185-94.

ANSI H35.1-2004, Alloy And Temper Designation Systems For Aluminum.

J.B. Cohen: Practical Organic Chemistry, Macmillan, London, UK, 356, p. 1910.

ASTM, “Standard Test Methods for Determining Average Grain Size,” 2004.

ASTM, “Standard Test Methods for Tension Testing of Metallic Materials,” 2008.

T.D. Topping, E.J. Lavernia, M. Kuruvilla, and T.S. Srivatsan: The Cyclic Fatigue, Damage Initiation, Propagation and Fracture Behavior of Cryomilled Aluminum Alloy 5083: Influence of Secondary Processing, Ed. M.A. Inman, Wiley, New York, NY, 2010.

T.D. Topping, Z. Zhang, E.J, Lavernia, T.S. Srivatsan, and M. Kuruvilla: Processing and Fabrication of Advanced Materials XIX, Ed. R.J.L.D. Bhattacharyya and T.S. Srivatsan, University of Auckland Press, Auckland, New Zealand, 2011, pp. 21–34.

W.F. Hosford: Mechanical Behavior of Materials, Cambridge University Press, New York, NY, 2005, pp. 188-206.

B.Q. Han, F.A. Mohamed, and E.J. Lavernia: J. Mater. Sci., 2003, vol. 38, no. 15, pp. 3319-24.

B. Ahn, R. Mitra, E.J. Lavernia, S.R. Nutt: J. Mater. Sci., 2010, vol. 45, no. 17, pp. 4790-95.

F. Shen, J. Zhou, Y. Liu, R. Zhu, S. Zhang, and Y. Wang: Comput. Mater. Sci., 2010, vol. 49, no. 2, pp. 226-35.

Y.T. Zhu: J. Mater. Eng. Perform., 2005, vol. 14, no. 4, pp. 467-72.

T. Shanmugasundaram, M. Heilmaier, B.S. Murty, and V.S. Sarma: Mater. Sci. Eng. A, 2010, vol. 527, nos. 29–30, pp. 7821-25.

E.L. Huskins, B. Cao, and K.T. Ramesh: Mater. Sci. Eng. A, 2010, vol. 527, no. 6, pp. 1292-98.

Y. Li, Y.H. Zhao, V. Ortalan, W. Liu, Z.H. Zhang, R.G. Vogt, N.D. Browning, E.J. Lavernia, and J.M. Schoenung: Mater.Sci. Eng. A, 2009, vol. 527, nos. 1–2, pp. 305-16.

V.L. Tellkamp, A. Melmed, and E.J. Lavernia: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2335-43.

Metals Handbook, Properties and Selection: Nonferrous Alloys and Special Purpose Materials, 10th ed., vol. 2, ASM, Materials Park, OH, 1990.

ASM Handbooks Online: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, Properties of Wrought Aluminum and Aluminum Alloys. vol. 2, 2002.

N.J. Petch: J. Iron Steel Inst., 1953, vol. 174, no. 1, pp. 25-28.

E.O. Hall: Proc. Phys. Soc. Lond. Sect. B, 1951, vol. 64, no. 381, pp. 747-53.

M.A. Meyers and K.K. Chawla: Mechanical Behavior of Materials, 1999, Prentice Hall, Upper Saddle River, NJ, pp. 247–81.

R.W. Hayes, D. Witkin, F. Zhou, and E.J. Lavernia: Acta Mater., 2004, vol. 52, no. 14, pp. 4259-71.

A. Forcellese and F. Gabrielli: Int. J. Mach. Tools Manufact., 2000, vol. 40, no. 9, pp. 1285-97.

O. Jensrud and K. Pedersen: J. Mater. Process. Tech., 1998, vols. 80–81, pp. 156-60.

G.E. Dieter: Metallurgy and Metallurgy Engineering Series, McGraw-Hill, New York, NY, 1961, pp. 118-45.

G.S. Ansell: Acta Metall., 1961, vol. 9, no. 5, pp. 518-19.

J.E. White: J. Met., 1965, vol. 17, no. 6, p. 587.

N. Hansen: Acta Metall., 1970, vol. 18, no. 1, p. 137.

R. Petkovic-Luton and J. Vallone: U.S. Patent 4619699, to Exxon Research and Engineering Company, 1986.

B.J.M. Aikin, R.M. Dickerson, D.T. Jayne, S. Farmer, and J.D. Whittenberger: Scripta Metall. Mater., 1994, vol. 30, no. 1, pp. 119-22.

R.W. Hayes, P.B. Berbon, and R.S. Mishra: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3855-61.

O. Susegg: Micron Microscop. Acta, 1992, vol. 23, nos. 1–2, pp. 223-24.

B.Q. Han and D.C. Dunand: Mater. Sci. Eng. A, 2000, vol. 277, nos. 1–2, pp. 297-304.

A. Kelly and R. Nicholson: Strengthening Methods in Crystals, Elsevier, New York, NY, 1971, p. 629.

ASM Handbooks Online, Alloy Phase Diagrams, Al Binary Alloy Phase Diagrams, Al-Mg. ASM International, vol. 3, 2002.

J.C. Huang, I.C. Hsiao, T.D. Wang, and B.Y. Lou: Scripta Mater., 2000, vol. 43, no. 3, pp. 213-20.

O.D. Sherby and J. Wadsworth: Progr. Mater. Sci., 1989, vol. 33, no. 3, pp. 169-221.

I. Roy, M. Chauhan, F.A. Mohamed, and E.J. Lavernia: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 721-30.

V.L. Tellkamp, E.J. Lavernia, and A. Melmed: J. Mater. Res., 2001, vol. 16, no. 4, pp. 938-44.

H. Tensi and H. Ehrhardt: Zeitschrift Fur Metallkunde, 1968, 59, no. 3.

M. Abbadi, P. Hahner, and A. Zeghloul: Mater. Sci. Eng. A, 2002, 337, no. 1–2, pp. 194-201.

J.Z. Chen, L. Zhen, L. Fan, S. Yang, S. Dai, and W. Shao: Transactions of Nonferrous Metals Society of China, 2009, vol. 19, no. 5, pp. 1071-75.

B. Li, B.Y. Caoa, K.T. Ramesha, and E. Ma: Acta Mater., 2009, vol. 57, no. 15, pp. 4500-07.

Y.H. Zhao, Y.Z. Guob, Q. Wei, T.D. Topping, A.M. Dangelewicz, Y.T. Zhu, T.G. Langdon, and E.J. Lavernia: Mater. Sci. Eng. A, 2009, vol. 525, nos. 1–2, pp. 68-77.

F. Tang and J.M. Schoenung: Mater. Sci. Eng. A, 2008, vol. 493, nos. 1–2, pp. 101-03.

R. Rodriguez, R.W. Hayes, P.B. Berbon, and E.J. Lavernia: Acta Mater., 2003, vol. 51, no. 4, pp. 911-29.

R.G. Vogt, Z. Zhang, T.D. Topping, E.J. Lavernia, and J.M. Schoenung: J. Mater. Process. Tech., 2009, vol. 209, no. 11, pp. 5046-53.

M. Jin, A.M. Minor, E.A. Stach, and J.W. Morris, Jr: Acta Mater., 2004, vol. 52, no. 18, pp. 5381-87.

D.S. Gianola, S. Van Petegem, M. Legros, S. Brandstetter, H. Van Swygenhoven, and K.J. Hemker: Acta Mater., 2006, vol. 54, no. 8, pp. 2253-63.

Acknowledgments

The authors gratefully acknowledge funding from The Office of Naval Research (Contract No. N00014-03-C0163) to produce and characterize the materials with the assistance of Dr. Piers Newbery. Also acknowledged is the Materials Design Institute, a joint research program between Los Alamos National Laboratory, LLC (LANS) and the College of Engineering, University of California–Davis (LANS Subcontract 25110-002-06) for funding to continue basic scientific research on the materials after they were produced. Mark R. van den Bergh and Cory A. Smith of DWA Aluminum Composites (Chatsworth, CA) are acknowledged for their technical expertise and manufacturing assistance during cryomilling. Henry (Mic) Meeks and Mark Fleming of Advance Materials & Manufacturing Technologies (Granite Bay, CA) are acknowledged for their technical advice and expertise during quasi-isostatic forging.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 17, 2011.

Rights and permissions

About this article

Cite this article

Topping, T.D., Ahn, B., Li, Y. et al. Influence of Process Parameters on the Mechanical Behavior of an Ultrafine-Grained Al Alloy. Metall Mater Trans A 43, 505–519 (2012). https://doi.org/10.1007/s11661-011-0849-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0849-y