Abstract

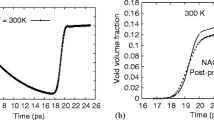

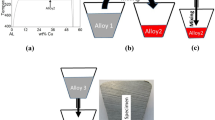

To understand the formation mechanism of hot tearing defects generated during casting, a knowledge of the pressure at which cavities form spontaneously in the liquid metal is required. In this work, molecular dynamics (MD) simulations were used to compute the cavitation pressure P c in liquid Al, where atomic interactions were described by an embedded atom method potential. The cavitation pressure was computed for various initial conditions and system sizes, and using classic nucleation theory, P c was extrapolated from MD length and time scales to those appropriate for casting. A value of P c ≈ −670 MPa was obtained, which is several orders of magnitude less than that predicted from hot tearing models. To investigate the possible role of heterogeneous nucleation sites, the P c simulations were repeated on solid–liquid systems that were simultaneously solidifying. In addition, the influence of a trace impurity Mg on the cavitation pressure was also investigated. Neither the impure Mg atoms nor the solid–liquid interfaces act as heterogeneous sites.

Similar content being viewed by others

Notes

The Clausius-Clapyeron equation predicts that the equilibrium melting point will decrease for the imposed negative pressures. For undercoolings less than 100 K (100 °C) the system simply equilibrated at the new melting temperature before cavitation was observed.

The pressure does not increase exactly to zero because liquid surfaces remain in the system after bubble growth is complete.

The value of the surface tension is lower than that for most liquid alloys, but it is consistent with the observation that the surface tension for this Al interatomic potential is known to be low (J.R. Morris, private communication).

References

M. Rappaz, J.M. Drezet, and M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 449-55.

J.A. Spittle and A.A. Cushway: Met. Technol., 1983, vol. 10, pp. 6-13.

A.S. Sabua and S. Viswanathan: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 243-55.

S. Vernede, J.A. Dantzig and M. Rappaz: Acta Mater., 2009, vol. 57, pp. 1554-69.

E. Herbert, S. Balibar, and F. Caupin: Phys. Rev. E, 2006, vol. 74, pp. 041603.

V.E. Vinogradov, P.A. Pavlov and V.G. Baidakov: Chem. Phys. Lett., 2009, vol. 474, pp. 294-96.

G.A. Carlson: J. Appl. Phys., 1975, vol. 46, 4069-70.

P.R. Williams, P.M. Williams and S.W.J. Brown: J. Phys. D, 1998, vol. 31, pp. 1923-26.

T.T. Bazhirov, G.E. Norman, and V.V. Stegailov: J. Phys., 2007, vol. 20, pp. 114113.

M.I. Mendelev, M.J. Kramer, C.A. Becker, and M. Asta: Phil. Mag., 2008, vol. 88, pp. 1723-50.

M.S. Daw and M.I. Baskes: Phys. Rev. Lett., 1983, vol. 50, pp. 1285-88.

S.J. Plimpton: J. Comput. Phys., 1995, vol. 117, pp. 1-19.

M.I. Mendelev, M. Asta, M.J. Rahman, and J.J. Hoyt: Phil. Mag., 2009, vol. 89, pp. 3269-85.

J. Monk, Y. Yang, M.I. Mendelev, M. Asta, J.J. Hoyt, and D.Y. Sun: Model. Simul. Mater. Sci. Engin., vol. 18, pp. 015004.

D.Y. Sun, M. Asta, and J.J. Hoyt, Phys. Rev. B, 2004, vol. 69, pp. 24108.

D. Kashchiev and A. Firoozabadi: J. Chem. Phys., 1993, vol. 98, pp. 4690-99.

H. Watanabe, M. Suzuki, and N. Ito: Phys. Rev. E, 2010, vol. 82, pp. 051604.

R.L. Davidchack and B.B. Laird: J. Chem. Phys., 1998, vol. 108, pp. 9452-62.

C.A. Becker, J.J. Hoyt, D. Buta, and M. Asta: Phys. Rev. E, 2007, vol. 75, pp. 61610.

T. Frolov and Y. Mishin: Model. Simul. Mater. Sci. Eng., 2010, vol. 18, pp. 074003.

J.J. Hoyt, M. Asta, and A. Karma: Phys. Rev. Lett., 2001, vol. 86, pp. 5530-33.

A.B. Phillion, S.L. Cockcraoft, and P.D. Lee: Mater. Sci. Eng. A, 2008, vol. 491, pp. 237-47.

R.S. Barnett, J.A. Taylor and D.H. St. John: 2004,Solidification of Aluminum Alloys Symposium, (TMS, Warrendale, PA), pp. 201-09.

I. Farup, M. Rappaz, and J.M. Drezet: Acta Metall., 2001, vol. 49, pp. 1261-69.

Acknowledgments

J.J.H. wishes to thank Prof. Alain Karma for several enlightening discussions. This work was supported by a Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 4, 2011.

Rights and permissions

About this article

Cite this article

Hoyt, J.J., Potter, A.A. A Molecular Dynamics Simulation Study of the Cavitation Pressure in Liquid Al. Metall Mater Trans A 43, 3972–3977 (2012). https://doi.org/10.1007/s11661-011-0846-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0846-1