Abstract

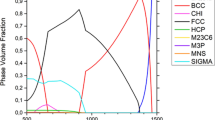

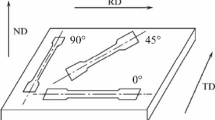

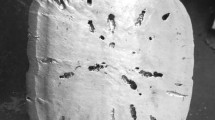

The mechanical properties of rolled duplex stainless steel (DSS) products manufactured by the current industrial process exhibit a strong anisotropy. This fact is evidently due to the two-phase nature of DSSs. During industrial rolling, not only the morphology of the microstructure changes from coarse-grained isotropic in the cast slab to fine-grained anisotropic in the coil, with both phases elongated in the rolling direction (RD), but also clear and intense crystallographic rolling textures develop, especially in the ferritic phase. The objective of the present work was to modify the industrial processing route and parameters in such a way that the strong anisotropy of DSS coils and sheets is decreased and the amount of potential applications made from DSSs by deep drawing or roll forming operations is increased. To achieve this goal, after the industrial cold rolling, a heat treatment is proposed with the aim of modifying the morphology and crystallographic texture of the ferritic grains by the assistance of an enforced transformation to sigma phase. The final product obtained by this modified route showed a microstructure with grains of austenite and ferrite randomly distributed and a significant decrease of the texture intensities due to the retransformation of sigma into ferrite. As a result, DSS EN 1.4462 displayed an almost isotropic mechanical behavior and an improved aptitude to deep drawing operations.

Similar content being viewed by others

References

J.O. Nilsson: Mater. Sci. Technol., 1992, vol. 8, pp. 685–700.

P. Lovland: Stainless Steel Europe, 1993, pp. 28–37.

K. Johansson: Proc. 6th Duplex Stainless Steels Conf., Associazione Italiana Metallurgia, Venezia, 2000, pp. 13–20.

M. Liljas: Proc. 6th Duplex Stainless Steel Science and Market Conf., Pentti Karjalainen and Staffan Hertman, eds., Helsinki, 2008, pp. 535–40.

M.P. Esteban, A. Iza-Mendia, and I. Gutiérrez: Proc. 6th Duplex Stainless Steel Science and Market Conf., Pentti Karjalainen and Staffan Hertman, eds., Helsinki, 2008, pp. 547–53.

I. Gutiérrez and A. Iza-Mendia: Duplex Stainless Steels, 1st ed., John Wiley & Sons Inc., London, 2009.

W.B. Hutchinson, K. Ushiola, and G. Runnsjö: Mater. Sci. Technol., 1985, vol. 1, pp. 728–31.

W.B. Hutchinson, U.V. Schlippenbach, and J. Jonsson: Proc. Duplex Stainless Steels ’86, Anon, The Netherlands, 1986, pp. 326–30.

J.L. Song and P.S. Bate: Acta Mater., 1997, vol. 45 (7), pp. 2747–57.

A. Mateo, L. Llanes, N. Akdut, J. Stolarz, and M. Anglada: Int. J. Fat., 2003, vol. 25, pp. 481–88.

G. Dieter: Mechanical Metallurgy, SI Metric edn., McGraw-Hill Book Company, London, 1988.

A. Ul-Haq, H. Weiland, and H.J. Bunge: Mater. Sci. Technol.,1994, vol. 10, pp, 289–98.

L. Duprez, B.C. De Cooman, and N. Akdut: Steel Res., 2001, vol. 72, pp. 311–16.

G. Fargas, N. Akdut, M. Anglada, and A. Mateo: ISIJ Int., 2008, vol. 48 (11), pp. 1596–1602.

X.G. Wang, D. Dumortier, and Y. Riquier: Proc. Duplex Stainless Steels ’91, Editions de Physique, Beaune, France, 1991, pp. 127–34.

T. Mori, K. Kondo, M. Igarashi, Y. Murata, and K. Horiuchi: Proc. 5th World Conf. on Duplex Stainless Steels, KCI Publishing BV, Maastricht, The Netherlands, 1997, pp. 55–61.

J.O. Nilsson, P. Kangas, T. Karlsson, and A. Wilson: Metall. Mater. Trans. A, 2001, vol. 31A, pp. 35–45.

W. Reick, M. Pohl, and A.F. Padihla: ISIJ Int., 1998, vol. 38 (6), pp. 567–71.

T. Ito, R. Matsuki, and H. Aoyama: Proc. 3rd Eur. Conf. Stainless Steels Science and Market, AIM, Sardinia, Italy, 1999, pp. 1–9.

G. Fargas, M. Anglada, and A. Mateo: J. Mater. Process. Technol., 2009, vol. 209, pp. 1770–82.

K. Forch, C.H. Gillessen, I. von Hagen, and W. Weißling: Stahl Eisen., 1992, vol. 112, pp. 53–62.

H.C. Lee and J. Gurland: Mater. Sci. Eng., 1978, vol. 41, pp. 125–33.

ASTM E517-81: Annual Book of ASTM Standards, Philadelphia, PA, p. 03.01.

ISO 11531, International Standards, 1994.

W.C. Oliver and G.M. Pharr: J. Mater. Res., 1992, vol. 7 (6), pp. 1564–82.

L. Karlsson: Proc. Duplex Stainless Steel ’97, KCI Publishing BV, Maastricht, The Netherlands, 1997, pp. 43–58.

D. Villalobos, A. Arbiter, and C. Maldonado: Rev. Mater., 2009, vol. 14 (3), pp. 1061–69.

A. Ul-Haq, H. Weiland, and H. Bunge: J. Mater. Sci., 1994, vol. 29, pp. 2168–76.

J. Keichel, G. Gottstein, and J. Foct: Proc. High Nitrogen Steel ’98, Trans Tech Publications Ltd., Stockholm, 1998, pp. 785–92.

J. Hirsch and K. Lücke: Acta Metall., 1988, vol. 36, pp. 2863–81.

H.P. Stüwe and J. Faustmann: Introducción a las Texturas de los Materiales Metálicos, Montecorvo, Madrid, 1969.

F.H. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Pergamon Press, New York, NY, 1996.

W.F. Hosford and W.A. Backofen: Fundamentals of Deformation Processing, Syracuse University Press, New York, NY, 1964.

K. Lange: Handbook of Metal Forming, McGraw-Hill Book Company, New York, NY, 1985.

W.F. Hosford and R.M. Caddell: Metal Forming. Mechanics and Metallurgy, 2nd ed. PTR Prentice Hall, Englewood Cliffs, NJ, 1993.

S. Kalpakjian: Manufacturing Processes for Engineering Materials, 3rd ed., Addison Wesley, Denton, NC, 1997.

Acknowledgments

One of the authors (AM) acknowledges the Spanish Ministerio de Ciencia e Innovación for the concession of Project No. MAT2009-14461 and the Direcció General de Recerca del Comissionat per a Universitats i Recerca de la Generalitat de Catalunya for recognizing CIEFMA as Grup de Recerca Consolidat 2009SGR 1285. The authors owe their gratitude to ALZ (today UGINE and ALZ, ArcelorMittal Group) for providing the material, to OCAS (today, next to OCAS, also Arcelor Research Industry Ghent, ArcelorMittal Group) for carrying out the texture measurements, and to the Technologic Center of Manresa (CTM) for its technical support in forming tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 1, 2010.

Rights and permissions

About this article

Cite this article

Fargas, G., Akdut, N., Anglada, M. et al. Reduction of Anisotropy in Cold-Rolled Duplex Stainless Steel Sheets by Using Sigma Phase Transformation. Metall Mater Trans A 42, 3472–3483 (2011). https://doi.org/10.1007/s11661-011-0744-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0744-6