Abstract

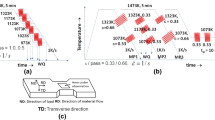

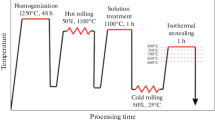

Plane-strain compression testing was carried out above, around, and below the A r3 temperature with the deformation temperature, T def, varying between 1323 K and 973 K (1050 °C and 700 °C), using Gleeble 3500, to develop uniform distribution of ultra-fine ferrite (UFF) grains. Prior austenite (γ) grain structure, developed after soaking at 1473 K (1200 °C), was mixed in nature, comprising both coarse- and fine-γ-grain sizes. Applying heavy deformation in a single pass, just above the austenite-to-ferrite (α) transformation temperature (A r3), and cooling to room temperature resulted in the formation of UFF grain sizes (average α-grain size ~2 to 3 μm), with the largest grain sizes extending up to ~10 to 12 μm. Water quenching just after deformation prevented the coarsening of UFF grains and restricted the largest grain sizes to under 6 μm. Although the ferrite grain structures appeared homogeneous in slowly cooled samples (cooling rate (CR) 1 K/s), careful observation revealed the presence of alternate bands of coarse- (5 to 10 μm) and fine-α grains (<1 to 3 μm). The final α-grain size distributions were explained in view of the starting γ-grain size variation, dynamic recrystallization (DRX) of γ, dynamic strain-induced γ-to-α transformation (DSIT), and DRX of α and grain growth during slow cooling. Electron backscattered diffraction analysis (EBSD) revealed the presence of a large fraction (70 to 80 pct) of high-angle boundaries, having misorientation ≥15 deg. Compared to the use of the single, heavy deformation pass, the application of a number of lighter passes between A e3 and A r3 temperatures is more suitable in industrial rolling conditions, and also has the potential of developing UFF grains with high-angle boundaries.

Similar content being viewed by others

Notes

LECO is a trademark of LECO Corporation, St. Joseph, MI.

References

T. Gladman: The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, 1997, Book 615.

D. Chakrabarti, C.L. Davis, and M. Strangwood: Mater. Charact., 2007, vol. 58, pp. 423–38.

S.J. Wu and C.L. Davis: J. Microsc., 2004, vol. 213, pp. 262–72.

D. Chakrabarti, C.L. Davis, and M. Strangwood: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1963–77.

J. Majta, J.G. Lenard, and M. Pietrzyk: ISIJ Int., 1996, vol. 36 (8), pp. 1094–1102.

R. Song, D. Ponge, D. Raabe, J.G. Speer, and D.K. Matlock: Mater. Sci. Eng. A, 2006, vol. 441, pp. 1–17.

R. Priestner and P.D. Hodgson: Mater. Sci. Technol., 1992, vol. 8, pp. 849–54.

R. Priestner and E. de los Rios: Met. Technol., 1980, vol. 7, pp. 309–16.

R. Priestner, Y.M. Al-Horr, and A.K. Ibraheem: Mater. Sci. Technol., 2002, vol. 18, pp. 973–80.

A.K. Ibraheem, R. Priestner, J.R. Bowen, P.B. Prangnell, and F.J. Humphreys: Ironmaking and Steelmaking, 2001, vol. 28 (2), pp. 203–08.

R. Priestner and A.K. Ibraheem: Mater. Sci. Technol., 2000, vol. 16, pp. 1267–72.

M.R. Hickson, R.K. Gibbs, and P.D. Hodgson: ISIJ Int., 1999, vol. 39, pp. 1176–80.

P.D. Hodgson, M.R. Hickson, and R.K. Gibbs: Scripta Mater., 1999, vol. 40, pp. 1179–84.

J.H. Beynon, R.E. Gloss, and P.D. Hodgson: Mater. Forum, 1992, vol. 16, pp. 37–42.

P.J. Hurley and P.D. Hodgson: Mater. Sci. Eng. A, 2001, vol. 302, pp. 206–14.

T. Morimoto, I. Chikushi, R. Kurahashi, and J. Yanagimoto: Proc. TMP 2004: 2nd Int. Conf. on Thermomechanical Processing of Steels, Stahleisen Verlag GmbH, Dusseldorf, Germany, 2004, pp. 415–22.

H. Beladi, G.L. Kelly, and P.D. Hodgson: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 450–63.

K. Mukherjee, S.S. Hazra, and M. Militzer: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2145–59.

P.R. Rios, I. de S. Bott, D.B. Santos, T.M.F. de Melo, and J.L. Ferreira: Mater. Sci. Technol., 2007, vol. 23 (4), pp. 417–22.

B. Eghbali and A. Abdollah-zadeh: Scripta Mater., 2006, vol. 54, pp. 1205–09.

H. Beladi, G.L. Kelly, A. Shokouhi, and P.D. Hodgson: Mater. Sci. Eng. A, 2004, vol. 371, pp. 343–52.

M.R. Hickson, P.J. Hurley, R.K. Gibbs, G.L. Kelly, and P.D. Hodgson: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1019–26.

B. Eghbali and A. Abdollah-Zadeh: Mater. Design, 2007, vol. 28, pp. 1021–26.

C. Zhang, N. Xiao, L. Hao, D. Li, and Y. Li: Acta Mater., 2009, vol. 57, pp. 2956–68.

T. Sakai and J.J. Jonas: Acta Metall., 1984, vol. 32 (2), pp. 189–209.

A.I. Fernández, P. Uranga, B. López, and J.M. Rodriguez-Ibabe: Mater. Sci. Eng. A, 2003, vol. 361, pp. 367–76.

G. Kugler and R. Turk: Acta Mater., 2004, vol. 52, pp. 4659–68.

T. Sakai, M. Ohashi, K. Chiba, and J.J. Jonas: Acta Metall., 1988, vol. 36, pp. 1781–90.

A. Najafi-Zadeh, J.J. Jonas, and S. Yue: Metall. Mater. Trans. A, 1992, vol. 23A, pp. 2607–17.

P.J. Hurley, B.C. Muddle, and P.D. Hodgson: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2985–93.

D. Chakrabarti, C.L. Davis, and M. Strangwood: Mater. Sci. Technol., 2009, vol. 25, pp. 8939–46.

E.I. Poliak and J.J. Jonas: Acta Mater., 1996, vol. 44, pp. 127–36.

J.-K. Choi, D.-H. Seo, J.-S. Lee, K.-K. Um, and W.-Y. Choo: ISIJ Int., 2003, vol. 43 (5), pp. 746–54.

F. Siciliano, Jr., K. Minami, T.M. Maccagno, and J.J. Jonas: ISIJ Int., 1996, vol. 36, pp. 1500–06.

Y. Misaka and T. Yoshimoto: J. Jpn. Soc. Technol. Plast., 1968, vol. 8, pp. 414–22.

J.D. Verhoeven: J. Mater. Eng. Perform., 2000, vol. 9, pp. 286–96.

Y.D. Huang, W.Y Yang, and Z.Q. Sun: J. Mater. Process. Technol., 2003, vol. 134, pp. 19–25.

M. Militzer and Y. Brechet: Metall. Mater. Eng. A, 2009, vol. 40A, pp. 2273–82.

P.D. Hodgson and R.K. Gibbs: ISIJ Int., 1992, vol. 32, pp. 1329–38.

Y.D. Huang and L. Froyen: J. Mater. Process. Technol., 2002, vol. 124, pp. 216–26.

S.Y. Ok and J.K. Park: Scripta Mater., 2005, vol. 52, pp. 1111–16.

R.K. Ray, M.P. Butron-Guillen, J. Jonas, and G.E. Ruddle: ISIJ Int., 1992, vol. 32 (2), pp. 203–12.

ASTM E384-99 Standard Test Method for Microindentation Hardness of Materials: Annual Book of ASTM Standards, ASTM, West Conshohocken, PA, 2000, vol. 3.01, pp. 437–60.

Acknowledgments

Sincere thanks to the Department of Science and Technology (DST), New Delhi, and the Research and Development Division (R&D) of Tata Steel for the provision of research funding. RDCIS, SAIL, Ranchi deserves special mention not only for providing the research material, but also for offering the Gleeble testing facility. Finally, special thanks are due to the Head of the Metallurgical and Materials Engineering Department, Chairman and P.I. of the Steel Technology Centre (STC), and Head of the Central Research Facility (CRF) in I.I.T. Kharagpur, for the provision of research facilities, and all the staff members (Pradip Sarkar and Sukanta Mandal deserve special mention) associated with those departments, for the help and support they have extended during this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 1, 2010.

Rights and permissions

About this article

Cite this article

Patra, S., Roy, S., Kumar, V. et al. Ferrite Grain Size Distributions in Ultra-Fine-Grained High-Strength Low-Alloy Steel After Controlled Thermomechanical Deformation. Metall Mater Trans A 42, 2575–2590 (2011). https://doi.org/10.1007/s11661-011-0668-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0668-1