Abstract

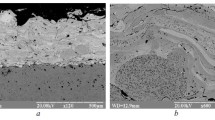

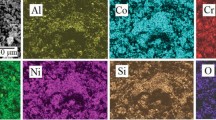

In order to develop new types of wear-resistant and corrosion-resistant materials, TiC and VC particles were injected into martensitic stainless steel X46Cr13 during spray forming, respectively. The microstructures of the spray-formed steel matrix composites under different processing conditions were investigated. The mechanisms of interactions between the injected particles and the matrix materials during spray forming and their effects on the microstructures of the composites were discussed and clarified based on experimental and theoretical investigations. The current results show that the injected particles may penetrate into the metallic droplets or adhere to the surface of the droplets and, therefore, are incorporated into the deposits to form metal matrix composites. Substantial heat transfer from superheated metallic melts to the room temperature carbide particles takes place as they are incorporated into the matrix material. The matrix steel solidifies in the vicinity of the carbides due to their chilling effect, and thus, the carbides may be engulfed in the matrix or pushed to the grain boundaries by the solidification fronts. TiC particles essentially retain their shape and size in the steel composites, while VC particles dissolve at least partially in the matrix and reprecipitate or form new phases in the final solidification and cooling stage. The porosity in the deposits increases with the gas to melt ratio (GMR) and the powder to melt ratio (PMR) by increasing atomizing gas pressure and powder feeding rate. Carbide type also affects the porosity of the deposits, because different thermodynamic properties of carbides change the heat dissipation and local solidification behavior of the mixture of matrix material and dissolved carbides. Moreover, the microstructure of the matrix material X46Cr13 is refined considerably with increasing GMR and PMR.

Similar content being viewed by others

Notes

LECO is a trademark of LECO Corporation, St. Joseph, MI.

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

P.R. Beeley, A.J. Baker, P.A. Blackmore, and A. Segal: in Solidification Technology in Foundry and Casthouse, The Metals Society, London, 1983, p. 398.

K. Das, T.K. Bandyopadhyay, and S. Das: J. Mater. Sci., 2002, vol. 37, pp. 3881–92.

J.M. Panchal, T. Vela, and T. Rabissch: Fabrication of Particulate Reinforced Composites, ASM INTERNATIONAL, Materials Park, OH, 1990, p. 245.

K.I. Parashivamurthy, R.K. Kumar, S. Seetharamu, and M.N. Chandrasekharaiah: J. Mater. Sci., 2001, vol. 36, pp. 4519–30.

T.Z. Kattamis and T. Suganuma: Mater. Sci. Eng. A, 1990, vol. A128, pp. 241–52.

A. Lawley and D. Apelian: Powder Metall., 1994, vol. 37, pp. 123–28.

E.J. Lavernia and Y. Wu: Spray Atomization and Deposition, John Wiley and Sons Ltd., Chichester, United Kingdom, 1996, pp. 354, 383–474.

A. Schneider, V. Uhlenwinkel, H. Harig, and K. Bauckhage: Mater. Sci. Eng. A, 2004, vol. A383, pp. 114–21.

J. Banhart, H. Grützner, and M. Knüwer: Proc. 1999 PM2TEC, Vancouver, BC, Canada, 1999, pp. 4-217–4-224.

A. Schneider, V. Uhlenwinkel, T. Wriedt, H. Harig, and K. Bauckhage: Proc. Int. Conf. Spray Deposition and Melt Atomization (SDMA2000), Bremen, June 26–28, 2000, vol. 1, pp. 219–29.

A. Schneider, V. Srivastava, and V. Uhlenwinkel: Z. Metallkd., 2004, vol. 95 (9), pp. 763–68.

B. Li and E.J Lavernia: Acta Mater.,1997, vol. 45, pp. 5015–30.

C. Cui, A. Schulz, V. Uhlenwinkel, F. Zobel, and H.-W. Zoch: Mater. Sci. Eng. Technol., 2010, vol. 41, pp. 524–31.

H.O. Pierson: Handbook of Refractory Carbides & Nitrides: Properties, Characteristics, Processing and Applications, Noyes Publications, Park Ridge, NJ, 1996, pp. 65–88.

R. Tiwari and H. Herman: Scripta Metall. Mater., 1991, vol. 25, pp. 1103–07.

S.I. Majagi, K. Ranganathan, A. Lawley, and D. Apelian: TMS Conf. Proc., TMS, Warrendale, PA, 1992, p. 139.

Y. Wu, J. Zhang, and E.J. Lavernia: Metall. Trans. B,1994, vol. 25B, pp. 135–47.

J. Zhang, Y. Wu, and E.J. Lavernia: Acta Metall. Mater., 1994, vol. 42, pp. 2955–72.

B. Li and E.J Lavernia: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 387–96.

U. Fritsching: Spray Simulation: Modelling and Numerical Simulation of Sprayforming Metals, Cambridge University Press, Cambridge, United Kingdom, 2004, pp. 156–62.

M. Gupta, I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia: J. Mater. Sci., 1991, vol. 26, pp. 6673–84.

E. Gutierrez-Miravete, E.J. Lavernia, G.M. Trapaga, J. Szekely, and N.J. Grant: Metall. Trans. A, 1989, vol. 20A, pp. 71–85.

M. Gupta, F. Mohamed, and E. Lavernia: Metall. Trans. A, 1992, vol. 23A, pp. 831–43.

W.E. Ranz and W.R. Marshall: Chem. Eng. Progr., 1952, vol. 28, pp. 141–47.

M. Krauss, H. Ye, C. Cui, and U. Fritsching: Proc. Int. Conf. Spray Deposition and Melt Atomization (SDMA2003), Universität Bremen, Bremen, Germany, June 22–25, 2003, vol. 2, pp. 7-3–7-16.

P. Mathur, D. Apelian, and A. Lawley: Acta Metall., 1989, vol. 37, pp. 429–43.

Thermo-Calc Software, http://www.thermocalc.com/.

L.E. Toth: Transition Metal Carbides and Nitrides, Academic Press, New York, NY, 1971, p. 124.

C. Cui, A. Schulz, K. Schimanski, and H.-W. Zoch: J. Mater. Process. Technol., 2009, vol. 209, pp. 5220–28.

S. Annavarapu and R. Doherty: Int. J. Powder Metall., 1993, vol. 29, pp. 331–43.

A. Lawley and A.G. Leatham: Mater. Sci. Forum, 1999, vols. 299–300, pp. 407–15.

V. Uhlenwinkel and N. Ellendt: Mater. Sci. Forum, 2007, vols. 534–536, pp. 429–32.

K.M. McHugh, V. Uhlenwinkel, and N. Ellendt: Proc. 2008 World Congress on Powder Metallurgy & Particulate Materials, Part 3: Compaction and Forming Processes, Washington, DC, 8–12 June, 2008, pp. 51–65.

P. Mathur, S. Annavarapu, D. Apelian, and A. Lawley: Mater. Sci. Eng. A, 1991, vol. A142, pp. 261–76.

D.E. Lawrynowicz, B. Li, and E.J. Lavernia: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 877–97.

Y. Wu and E.J. Lavernia: Metall. Trans. A, 1992, vol. 23A, pp. 2923–37.

G. Krauss: Steels: Processing, Structure, and Performance, ASM INTERNATIONAL, Materials Park, OH, 2005, pp. 15–22.

P.S. Grant: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1520–29.

Acknowledgments

The authors gratefully acknowledge the financial support of the German Federal Ministry of Economics and Technology via the Federation of Industrial Research Associations (Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e.V.; AiF) within the program AiF238ZN at the Foundation Institute for Materials Science (IWT, Bremen). Gratitude is also expressed to Dörrenberg Edelstahl GmbH (Engelskirchen) and Deutsche Edelstahlwerke GmbH (DEW, Siegen) for supplying the steels.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 5, 2010.

Rights and permissions

About this article

Cite this article

Cui, C., Schulz, A., Uhlenwinkel, V. et al. Spray-Formed Stainless Steel Matrix Composites with Co-Injected Carbide Particles. Metall Mater Trans A 42, 2442–2455 (2011). https://doi.org/10.1007/s11661-011-0633-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0633-z