Abstract

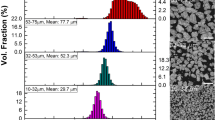

A Zircaloy recycle process is being investigated based on the underlying principle that Zr reacts with H2 to form ZrH2, which is the same reaction that produces performance limiting ZrH2 formations in reactor cladding. However, in the proposed application, hydride formation is an enabling phenomenon that will embrittle and crumble Zircaloy as a precursor for milling and dehydration to form Zircaloy metal powder. Hydride formation experiments were performed to quantify the primary process variables of time and temperature. These experiments were performed by hydriding nuclear grade Zircaloy-4 tubes under flowing gas (Ar-5 pct H2) for various times and temperatures. The results were used to create a correlation for the formation of zirconium hydride as a function of time and temperature. Further, it was observed that it was much more effective to hydride the Zircaloy-4 tubes at temperatures below the α-β-δ eutectoid temperature of 818 K (545 °C), presumably related to the high hydrogen solubility of β-Zr. Samples treated below this temperature readily crumbled during the hydride formation reaction and were subsequently easily ground to powder, making this the ideal temperature range for the proposed recycle method. Hydrogen pickup was faster above 818 K (545 °C), but the samples were generally tougher.

Similar content being viewed by others

References

D. Bodanski: Phys. Today, 2006, vol. 59 (12), pp. 80–81.

G.F. Vandegrift, M.C. Regalbuto, S. Aase, A. Bakel, T.J. Battisti, D. Bowers, J.P. Byrnes, M.A. Clark, J.W. Emery, J.R. Falkenberg, A.V. Gelis, C. Pereira, L. Hafenrichter, Y. Tsai, K.J. Quigley, and M.H. Vander Pol: Proc. ATALANTE 2004, Nimes, France, 2004.

G.F. Vandegrift: “Transformation of UREX Effluents to Solid Oxides by Concentration, Denitration, and Calcination,” ANL-00/25, Argonne National Lab., Argonne, IL, 2000.

F. Smith and R. Dimenna: “Modeling the UREX+3a Process Using Aspen Plus Coupled with AMUSE,” WSRC-STI-2008-00013, Savannah River National Lab., Aiken, SC, 2008.

S.M. McDeavitt, A. Parkison, A.R. Totemeier, and J.J. Wegener: Mater. Sci. Forum, 2007, vols. 561–565, pp. 1733–36.

S.M. McDeavitt, D.T. Kraemer, A. Parkison, A.R. Totemeier, and J.J. Wegener: Proc. American Nuclear Society Winter Meeting, Washington DC, Nov. 13–17, 2005; ANS Trans., 2005, vol. 93, p. 743.

G.D. Moon and P. Rudling, eds.: Zirconium in the Nuclear Industry: 13th Int. Symp., ASTM INTERNATIONAL, West Conshohocken, PA, 2002.

J.M. Markowitz: “Internal Zirconium Hydride Formation in Zircaloy Fuel Element Cladding under Irradiation,” WAPD-TM-351, Westinghouse Electric Corp., Bettis Atomic Power Lab., Pittsburgh, PA, 1963.

K. Une, K. Nogita, S. Ishimoto, and K. Ogata: J. Nucl. Sci. Technol., 2004, vol. 41, pp. 731–40.

S. Yamanaka, K. Yoshioka, M. Uno, M. Katsura, H. Anada, T. Matsuda, and S. Kobayashi: J. Alloys Compd., 1999, vols. 293–295, pp. 23–29.

G.L. Miller: Metallurgy of the Rarer Metals-2: Zirconium, 2nd ed., Academic Press Inc. Publishers, New York, NY, 1957.

B. Lustman and F. Kerze, Jr., eds.: The Metallurgy of Zirconium, McGraw-Hill Book Company, Inc., New York, NY, 1955, pp. 553–607.

R.A. Hard and J.A. Megy: U.S. Patent 4470847, 1984.

H.S. Kalish: Zirconium and Zirconium Alloys, Symp. American Society of Metals, 1953, p. 331.

W.D. Callister and D.G. Rethwisch: Fundamentals of Materials Science and Engineering: an Integrated Approach, 3rd ed., John Wiley & Sons, Hoboken, NJ, 2008.

W.M. Mueller, J.P. Blackledge, and G.G. Libowitz, eds.: Metal Hydrides, Academic Press, New York, NY, 1968.

C.E. Coleman and J.F.R. Ambler: Zirconium in the Nuclear Industry, ASTM-STP, 1977, vol. 633, pp. 589–607.

L.A. Simpson and K. Nuttall: Zirconium in the Nuclear Industry, ASTM-STP, 1977, vol. 633, pp. 608–29.

L.A. Simpson and M.P. Puls: Metall. Trans. A, 1979, vol. 10A, pp. 1093–1105.

F.H. Huang and W.J. Mills: Metall. Trans. A, 1991, vol. 22A, p. 2049.

Acknowledgments

This work was performed under the United States Department of Energy Nuclear Energy Research Initiative project (NERI ID No. DE-FC07-05ID14656). The authors acknowledge D.T. Kraemer and A.R. Totemeier for supportive contributions to the research reported in this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 22, 2010.

Rights and permissions

About this article

Cite this article

Parkison, A.J., McDeavitt, S.M. Hydride Formation Process for the Powder Metallurgical Recycle of Zircaloy from Used Nuclear Fuel. Metall Mater Trans A 42, 192–201 (2011). https://doi.org/10.1007/s11661-010-0425-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0425-x