Abstract

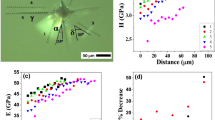

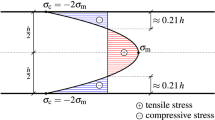

To understand how hardness, the key design parameter for applications of brittle solids such as glass concerning contact deformation, is affected by loading rate variation, nanoindentation with a Berkovich tip was used to measure the nanohardness of a 330-μm-thick soda-lime-silica glass as a function of loading rate (1 to 1000 mN·s−1). The results showed for the very first time that, with variations in the loading rate, there was a 6 to 9 pct increase in the nanohardness of glass up to a threshold loading rate (TLR), whereafter it did not appreciably increase with further increase in loading rate. Further, the nanohardness data showed an indentation size effect (ISE) that obeyed the Meyer’s law. These observations were explained in terms of a strong shear stress component developed just beneath the nanoindenter and the related shear-induced deformation processes at local microstructural scale weak links. The significant or insignificant presence of shear-induced serrations in load depth plots and corresponding scanning electron microscopic evidence of a strong or mild presence of shear deformation bands in and around the nanoindentation cavity supported such a rationalization. Finally, a qualitative picture was developed for different deformation processes induced at various loading rates in glass.

Similar content being viewed by others

References

R.F. Cook and G.M. Pharr: J. Am. Ceram. Soc., 1990, vol. 73, pp. 787–817.

B.R. Lawn: J. Am. Ceram. Soc., 1998, vol. 81, pp. 1977–94.

T. Burgess and M. Ferry: Mater. Today, 2009, vol. 12, pp. 24–32.

N.K. Mukhopadhyay and P. Paufler: Int. Mater. Rev., 2006, vol. 51, pp. 209–45.

K.W. Peter: J. Non-Cryst. Solids, 1970, vol. 5, pp. 103–15.

A. Arora, D.B. Marshall, and B.R. Lawn: J. Non-Cryst. Solids, 1979, vol. 31, pp. 415–28.

J.T. Hagan: J. Mater. Sci., 1980, vol. 15, pp. 1417–24.

F. Ernsberger: J. Non-Cryst. Solids, 1977, vol. 25, pp. 293–321.

S. Yoshida, J.C. Sangleboeuf, and T. Rouxel: J. Mater. Res., 2005, vol. 20, pp. 3404–12.

T.M. Gross and M. Tomozawa: J. Non-Cryst. Solids, 2008, vol. 354, pp. 4056–62.

C.R. Kurkjian, G.W. Kammlott, and M.M. Chaudhri: J. Am. Ceram. Soc., 1995, vol. 78, pp. 737–44.

T. Miura, Y. Benino, R. Sato, and T. Komatsu: J. Eur. Ceram. Soc., 2003, vol. 23, pp. 409–16.

H. Ji, V. Keryvin, T. Rouxel, and T. Hammouda: Scripta Mater., 2006, vol. 55, pp. 1159–62.

S.P. Gunnasekera and D.G. Holloway: Phys. Chem. Glasses, 1973, vol. 14, pp. 45–52.

C.J. Fairbanks, R.S. Polvani, S.M. Wiederhorn, B.J. Hockey, and B.R. Lawn: J. Mater. Sci. Lett., 1982, vol. 1, pp. 391–93.

M. Yoshioka and N. Yoshioka: J. Appl. Phys., 1995, vol. 78, pp. 3431–37.

L. Ainsworth: J. Soc. Glass Technol., 1954, vol. 38, pp. 479–500.

L. Hohne: Ullner C. VDI Berichte., 1995, vol. 1194, pp. 119–28.

K. Suzuki, Y. Benino, T. Fujiwara, and T. Komatsu: J. Am. Ceram. Soc., 2002, vol. 85, pp. 3102–04.

J. Malzbender: J. Am. Ceram. Soc., 2003, vol. 86, pp. 2237–38.

T. Komatsu: J. Am. Ceram. Soc., 2003, vol. 86, pp. 2239–40.

C.L. Eriksson, P.L. Larsson, and D.J. Rowcliffe: Mater. Sci. Eng. A, 2003, vol. 340, pp. 193–203.

J. Gong, H. Miao, and Z. Peng: Mater. Lett., 2004, vol. 58, pp. 1349–53.

Z. Peng, J. Gong, and H. Miao: J. Eur. Ceram. Soc., 2004, vol. 24, pp. 2193–2201.

K.O. Kese, Z.C. Li, and B. Bergman: Mater. Sci. Eng. A, 2005, vol. 404, pp. 1–8.

K.O. Kese and Z.C. Li: Scripta Mater., 2006, vol. 55, pp. 699–702.

P. Grau, G. Berg, H. Meinhard, and S. Mosch: J. Am. Ceram. Soc., 1998, vol. 81, pp. 1557–64.

D.J. Morris and R.F. Cook: J. Am. Ceram. Soc., 2004, vol. 87, pp. 1494–1501.

R.K. Kalia, A. Nakano, I. Szlufarska, and P. Vashishta: Proc. Users Group Conf. (DOD UGC’04) by IEEE Computer Society, Williamsburg, VA, June 7–11, 2004.

W.C. Oliver and G.M. Pharr: J. Mater. Res., 1992, vol. 7, pp. 1564–83.

C.A. Schuh, T.G. Nieh, and Y. Kawamura: J. Mater. Res., 2002, vol. 17, pp. 1651–54.

Y.I. Golovin, V.I. Ivolgin, V.A. Khonik, K. Kitagawa, and A.I. Tyurin: Scripta Mater., 2001, vol. 45, pp. 947–52.

C.A. Schuh and T.G. Nieh: Acta Mater., 2003, vol. 51, pp. 87–99.

O. Shikimaka and D. Grabco: J. Phys. D Appl. Phys., 2008, vol. 41, pp. 301–07.

H. Bei, Z.P. Lu, and E.P. George: Phys. Rev. Lett., 2004, vol. 93, pp. 125504-1–125504-4.

C.E. Packard and C.A. Schuh: Acta Mater., 2007, vol. 55, pp. 5348–58.

H. Shang, T. Rouxel, M. Buckley, and C. Bernard: J. Mater. Res., 2006, vol. 21, pp. 632–38.

R.W.K. Honeycombe: Plastic Deformation of Metals, 2nd ed., Edward Arnold Ltd., London, 1984, pp. 123–38.

A. Puthucode, R. Banerjee, S. Vadlakonda, R. Mirshams, and M.J. Kaufman: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1552–59.

S. Shim, H. Bei, E.P. Georgea, and G.M. Pharr: Scripta Mater., 2008, vol. 59, pp. 1095–98.

J. Li, K.J. Van Vliet, T. Zhu, S. Yip, and S. Suresh: Nature, 2002, vol. 418, pp. 307–10.

Q. Ma and D.R. Clarke: J. Mater. Res., 1995, vol. 10, pp. 853–63.

S.J. Bull, T.F. Page, and E.H. Yoffe: Phil. Mag. Lett., 1989, vol. 59, pp. 281–88.

E.O. Bernhardt: Z. Metallkd., 1941, vol. 33, pp. 135–44.

W.D. Nix and H. Gao: J. Mech. Phys. Solids, 1998, vol. 46, pp. 411–25.

M.F. Horstemeyer, M.I. Baskes, and S.J. Plimpton: Acta Mater., 2001, vol. 49, pp. 4363–74.

A. Iost and R. Bigot: J. Mater. Sci., 1996, vol. 31, pp. 3573–77.

H. Li, A. Ghosh, Y.H. Han, and R.C. Bradt: J. Mater. Res., 1993, vol. 8, pp. 1028–32.

M.V. Swain and M. Wittling: Fracture Mechanics of Ceramics, R.C. Bradt, ed., Plenum Press, New York, NY, 1996, vol. 11, pp. 379–87.

J. Gong and Z. Guan: Mater. Lett., 2001, vol. 47, pp. 140–44.

Y.X. Gao and H. Fan: J. Mater. Sci., 2002, vol. 37, pp. 4493–98.

A. Dey, A.K. Mukhopadhyay, S. Gangadharan, M.K. Sinha, and D. Basu: J. Mater. Sci., 2009, vol. 44, pp. 4911–18.

C. Hays and E.G. Kendall: Metallography, 1973, vol. 6, pp. 275–82.

H. Li and R.C. Bradt: Mater. Sci. Eng. A, 1991, vol. 142, pp. 51–61.

H.G.M. Kreuzer and R. Pippan: Acta Mater., 2007, vol. 55, pp. 3229–35.

Acknowledgments

The authors are grateful to the Director, Central Glass and Ceramic Research Institute (CGCRI), Kolkata, for his kind permission to publish this article. In addition, the authors appreciate the infrastructural support received from all colleagues and particularly those received from the colleagues of the Mechanical Test Section at CGCRI. Finally, the authors gratefully acknowledge the financial support received from CSIR (Network Project TAREMAC No. NWP 0027). One of the authors (AD) also earnestly acknowledges the grant of a Senior Research Fellowship from CSIR, India (ACK No. 141011/2K8/2).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 1, 2009.

Rights and permissions

About this article

Cite this article

Chakraborty, R., Dey, A. & Mukhopadhyay, A.K. Loading Rate Effect on Nanohardness of Soda-Lime-Silica Glass. Metall Mater Trans A 41, 1301–1312 (2010). https://doi.org/10.1007/s11661-010-0176-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0176-8