Abstract

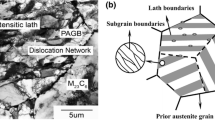

High-purity Cu (99.995 pct pure) rods were cryogenically rolled through a 90 pct reduction in area and given a very brief low-temperature anneal. The resultant material was highly textured, had very low internal strains, and had a broad distribution of grain sizes with an average grain size of 150 to 300 nm. Samples were tested in stress-control tension-tension fatigue. Fatigue life was strongly improved over that of coarse-grain (CG) copper. The cycling caused significant softening and grain growth, especially at the lower stress amplitudes. Plastic strain was small but creep was evident. Clusters of long parallel protrusions that were quite uniformly spaced about 100 nm apart formed on the sample surfaces during fatiguing. Among the various microstructures seen in the fatigued specimens, transmission electron microscopy (TEM) pictures taken just inside the surface showed parallel dislocation lines many micrometers in length spaced about 100 nm from one another. It is possible that these dislocations are involved in the formation of the protrusions.

Similar content being viewed by others

References

A. Vinogradov, V. Patlan, S. Hashimoto, and K. Kitagawa: Phil. Mag. A, 2002, vol. 82, pp. 317–35.

A. Vinogradov, S. Hashimoto, V. Patlan, and K. Kitagawa: Mater. Sci. Eng. A, 2001, vols. A319–A321, pp. 862–66.

L. Kunz, P. Lukás, and M. Svoboda: Mater. Sci. Eng. A, 2006, vol. A424, pp. 97–104.

P. Lukás. L. Kunz, and M. Svoboda: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1910–15.

H. Mughrabi and H.W. Höppel: MRS Proceedings, D. Farkas et al., eds., Materials Research Society, Warrendale, PA, 2001, vol. 634, pp. B2.1.1–B2.1.12.

H.W. Höppel, Z.M. Zhou, H. Mughrabi, and R.Z. Valiev: Phil. Mag. A, 2002, vol. 82, pp. 1781–94.

H. Mughrabi, H.W. Höppel, and M. Kautz: Scripta Mater., 2004, vol. 51, pp. 807–12.

H.W. Höppel, M. Kautz, C. Xu, M. Murashkin, T.G. Langdon, R.Z. Valiev, and H. Mughrabi: Int. J. Fatigue, 2006, vol. 28, pp. 1001–10.

M. Goto, S.Z. Han, T. Yakushiji, C.Y. Lim, and S.S. Kim: Scripta Mater., 2006, vol. 24, pp. 2101–06.

M. Goto, S.Z. Han, S.S. Kim, N. Kawagoishi, and C.Y. Lim: Scripta Mater., 2007, vol. 57, pp. 293–96.

S.D. Wu, Z.G. Wang, C.B. Jiang, G.Y. Li, I.V. Alexandrov, and R.Z. Valiev: Mater. Sci. Eng. A, 2004, vols. A387–A389, pp. 560–64.

S.R. Agnew and J.R. Weertman: Mater. Sci. Eng. A, 1998, vol. A244, pp. 145–53.

S.R. Agnew, A. Yu. Vinogradov, S. Hashimoto, and J.R. Weertman: J. Electron. Mater., 1999, vol. 28, pp. 1038–44.

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Prog. Mater. Sci., 2000, vol. 45, pp. 103–89.

Physical Metallurgy, 3rd ed., R.W. Cahn and P. Haasen, eds., North Holland Physics Publishing, New York, NY, 1983, pp. 1563–78.

A.B. Witney, P.G. Sanders, J.R. Weertman, and J.A. Eastman: Scripta Metall. Mater., 1995, vol. 33, pp. 2025–30.

H.P. Klug and L.E. Alexander: X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed., Wiley, New York, NY, 1974, pp. 661–65.

C.J. Shute, B.D. Myers, S. Xie, T.W. Barbee Jr., A.M. Hodge, and J.R. Weertman: Scripta Mater., 2009, vol. 60, pp. 1073–77.

D. Tabor: The Hardness of Metals, Oxford University Press, London, 1951, p. 107.

B. Moser, T. Hanlon, K.S. Kumar, and S. Suresh: Scripta Mater., 2006, vol. 54, pp. 1151–55.

B.E. Warren: X-ray Diffraction, Dover, New York, 1990, p. 290.

Kai Zhang and J.R. Weertman: Appl. Phys. Lett., 2005, vol. 87, pp. 061921-1–061921-3.

K. Zhang, I.V. Alexandrov, A.R. Kilmametov, R.Z. Valiev, and K. Lu: J. Phys. D: Appl. Phys., 1997, vol. 30, pp. 3008–15.

Y. Amouyal and E. Rabkin: Acta Mater., 2007, vol. 55, pp. 6681–89.

Acknowledgments

We express our thanks and gratitude to Professor S. Mostovoy and Mr. R. Janota for use of, and assistance with, the rolling mill at the Illinois Institute of Technology, which was used to prepare the Cu samples. The authors acknowledge the facility support of the Electron Probe Orientation Center at Northwestern University. This research was supported by the United States Department of Energy, Office of Science, Office of Basic Energy Sciences, under Grant No. DE-FG02ER-460002.

Author information

Authors and Affiliations

Corresponding author

Additional information

The Institute of Metals Lecture, established in 1921, recognizes an outstanding scientific leader who is selected to present a lecture at the TMS Annual Meeting. The Robert Franklin Mehl Award was established in 1972.

Julia Weertman received her BS, MS, and DSc in Physics at the Carnegie Institute of Technology (now CMU). She worked in ferromagnetic spin wave resonance at the United States Naval Research Laboratory for 6 years, took some time off to raise her family, and has since then been on the faculty of the Department of Materials Science and Engineering at Northwestern University, where she is now Walter P. Murphy Professor Emerita. Professor Weertman’s areas of research center on the mechanical behavior of metals and alloys and the underlying phenomena that give rise to the observed behavior. Her research currently is focused on determining the mechanical properties of a variety of nanostructured materials, their synthesis, the characterization of their structure, and the study of the deformation mechanisms in this small grain size regime. Professor Weertman is a member of the National Academy of Engineering and the American Academy of Arts and Sciences and is a Fellow of TMS, ASM International, and the Neutron Scattering Society of America. She received the Von Hippel Award from the Materials Research Society and the Achievement Award from the Society of Women Engineers. She served on the MRS Board of Directors, is on the Editorial Board of the MRS Bulletin, and currently is chair of the Awards Committee of the MRS.

Rights and permissions

About this article

Cite this article

Zhang, K., Weertman, J. Microstructural Changes Produced by Fatigue in High-Purity Copper Severely Deformed by Cryogenic Rolling. Metall Mater Trans A 40, 2255–2263 (2009). https://doi.org/10.1007/s11661-009-9925-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9925-y