Abstract

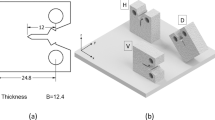

Understanding microstructure formation during high-pressure die casting (HPDC) is important for the effective quality control of high-pressure diecast aluminum-alloy components for high-integrity applications. In this study, two HPDC-specific aluminum alloys, AlSi4MgMn and AlMg5Si2Mn, were cast into tensile test bars by cold-chamber (CC) HPDC. The microstructures of the tensile bar specimens were characterized at different length scales, from the scale of the casting to the scale of the eutectic interlamellar spacing. The results show that the salient as-cast microstructural features, e.g., externally solidified crystals (ESCs), defect bands, the surface layer, grain size distribution, porosity, and hot tears were similar for both alloys. The formation of these features can be understood by considering the influence of flow and solidification during each stage of the HPDC process.

Similar content being viewed by others

Notes

Bühler is a trademark of Bühler Druckguss AG, Uzwil, Switzerland.

Gatan is a trademark of Gatan Inc., Pleasanton, CA.

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

Thermo-Calc is a trademark of Thermo-Calc Software, Stockholm, Sweden.

Thermotech is a trademark of Thermotech Ltd., Guildford, UK.

References

S. Brusethaug and J.S. Maeland: Cast. Plant Technol. Int., 2004, vol. 20 (4), pp. 16–23.

J.L. Jorstad: Die Cast. Eng., 2008, vol. 52 (5), pp. 18–20.

C. Dorum, H.I. Laukli, O.S. Hopperstad, and M. Langseth: Eur. J. Mech. A: Solids, 2009, vol. 28 (1), pp. 1–13.

H. Koch, U. Hielscher, H. Sternau, and A.J. Franke: in Silafont-36: The New Low-Iron High-Pressure Die-Casting Alloy, J. Evans, ed., TMS, Warrendale, PA, 1995, pp. 1011–18.

U. Hielscher, H. Sternau, H. Koch, and A.J. Franke: in Magsimal-59: An AlMgMnSi-Type Squeeze-Casting Alloy Designed for Temper F, W. Hale, ed., TMS, Warrendale, PA, 1996, pp. 933–37.

K. Greven and D. Dragulin: Ductile High Pressure Die Casting—Heat Treated or Temper F?, Proc. 2nd Int. Light Met. Technol. Conf., St. Wolfgang, Austria, H. Kaufmann, ed., ARC Leichtmetallkompetenzzentrum Ranshofen GmbH, Ranshofen, Austria, 2005, pp. 221–25.

M.R. Ghomashchi: J. Mater. Process. Technol., 1995, vol. 52 (2–4), pp. 193–206.

X.P. Niu, K.K. Tong, B.H. Hu, and I. Pinwill: Int. J. Cast Met. Res., 1998, vol. 11, pp. 105–12.

Z.W. Chen: Mater. Sci. Eng. A, 2003, vol. 348 (1–2), pp. 145–53.

M.R. Ghomashchi and G.A. Chadwick: Met. Mater., 1986, vol. 2, pp. 477–81.

M.M. Avedesian and H. Baker: Magnesium and Magnesium Alloys, ASM INTERNATIONAL, Materials Park, OH, 1999, p. 66.

P. Beeley: Foundry Technology, Butterworth-Heinemann, Oxford, United Kingdom, 2001, p. 598.

R.N. Lumley, R.G. Odonnell, D.R. Gunasegaram, and M. Givord: Metall. Mater. Trans. A, 2007, vol. 38A (10), pp. 2564–74.

F. Cosse, J.J. Perrier, J.S. Iversen, and S. Brusethaug: in Aluminium P, AS NH, eds., Pechiney Aluminium and Norsk Hydro AS, High Ductility Aluminum Alloy for Die Casting, France, 2003, Patent No. WO03006698.

R. Franke, D. Dragulin, A. Zovi, and F. Casarotto: Metall. Ital., 2007, May, pp. 21–25.

“ASTM B557M-06: Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric),” Annual Book of ASTM Standards, ASTM International, West Conshohocken, Philadelphia, PA, 2007, vol. 02.02, pp. 441–55.

H.I. Laukli, O. Lohne S. Sannes, H. Gjestland, and L. Arnberg: Int. J. Cast Met. Res., 2003, vol. 16 (6), pp. 515–21.

A.L. Bowles, K. Nogita, M. Dargusch, C. Davidson, and J. Griffiths: Mater. Trans., 2004, vol. 45 (11), pp. 3114–19.

H.I. Laukli, L. Arnberg, and O. Lohne: Int. J. Cast Met. Res., 2005, vol. 18 (2), pp. 65–72.

S. Sannes and H. Westengen: Proc. Int. Conf. Magnesium Alloys and Their Applications, B.L. Mordike and K.U. Kainer, eds., Frankfurt DGM, Germany, Werkstoff Informationsgesellschaft, Frankfurt, Germany, 1998, pp. 223–28.

S.R. Agnew, K.C. Liu, E.A. Kenik, and S. Viswanathan: in Magnesium Technology 2000, H.I. Kaplan, J. Hyrn, and B. Clow, eds., TMS, Warrendale, PA, 2000, pp. 285–90.

P.D.D. Rodrigo and V. Ahuja: Proc. 2nd Israeli Conf. on Magnesium Sci. Technol., Dead Sea, Israel, E. Aghion and D. Eliezer, eds., Magnesium Research Institute, Israel, 2000, pp. 97–104.

A.L. Bowles, J.R. Griffiths, and C.J. Davidson: in Magnesium Technology, J. Hyrn, ed., TMS, Warrendale, PA, 2001, pp. 161–73.

C. Pitsaris, T. Abbott, and C.J. Davidson: Proc. 1st Int. Light Metal Technology Conf., A.K. Dahle, ed., CAST CRC, Brisbane, Australia, 2003, pp. 223–61.

H. Cao and M. Wessén: Int. J. Cast Met. Res., 2005, vol. 18 (6), pp. 377–84.

H.I. Laukli, C.M. Gourlay, A.K. Dahle, and O. Lohne: Mater. Sci. Eng. A, 2005, vols. 413–414, pp. 92–97.

Z. Fan, G. Liu, and Y. Wang: J. Mater. Sci., 2006, vol. 41, pp. 3631–44.

C.M. Gourlay, H.I. Laukli, A.K. Dahle: Metall. Mater. Trans. A, 2007, vol. 38 (8), pp. 1833–44.

S. Sannes, H. Gjestland, H. Westengen, H.I. Laukli, and O. Lohne: J. Mater. Manuf., 2003, vol. 112, pp. 1–9.

L. Wang, T. Nguyen, T. Savage, and C.J. Davidson: Int. J. Cast Met. Res., 2003, vol. 16 (4), pp. 409–17.

H. Gjestland, S. Sannes, J. Svalestuen, and H. Westengen: J. Mater. Manuf., 2005, vol. 114, pp. 67–73.

M. Gershenzon, P.W. Rohan, and M.T. Murray: Trans. 20th Int. Die Casting Congr. Expos., North American Die Casting Association, Wheeling, IL, 1999, pp. 305–15.

H.I. Laukli, C.M. Gourlay, and A.K. Dahle: Metall. Mater. Trans. A, 2005, vol. 36 (3A), pp. 805–18.

N.A. El-Mahallawy, M.A. Taha, E. Pokora, and F. Klein: J. Mater. Process. Technol., 1998, vol. 73, pp. 125–38.

T. Schnorf, J.-P. Gabathuler, and T. Imwinkelried: in Modeling of Casting, Welding, and Advanced Solidification Processes, D.M. Stefanescu, J.A. Warren, M.R. Jolly, and M.J.M. Krane, eds., TMS, Warrendale, PA, 2003, pp. 717–24.

G. Dour, M.S. Dargusch, C.J. Davidson, and A. Nef: J. Mater. Process. Technol., 2005, vol. 169, pp. 223–33.

C.M. Gourlay and A.K. Dahle: Nature, 2007, vol. 445, pp. 70–73.

C.M. Gourlay, B. Meylan, A.K. Dahle: Acta Mater., 2008, vol. 56, pp. 3403–13.

M.C. Flemings: Solidification Processing, McGraw-Hill, New York, NY, 1974, pp. 246–52.

S.G. Lee, G.R. Patel, and A.M. Gokhale: Scripta Mater., 2005, vol. 52, pp. 1063–68.

C.M. Dinnis, J.A. Taylor, and A.K. Dahle: Scripta Mater., 2005, vol. 53, pp. 955–58.

D. Stockdale and I. Wilkinson: J. Inst. Met., 1926, vol. 36, pp. 313–24.

G.K. Sigworth: AFS Transactions: The Modification of Al-Si Casting Alloys: Important Practical and Theoretical Aspects, American Foundry Society, Schaumburg, IL, 2008, pp. 115–39.

A. Hamasaiid, G. Dour, M.S. Dargusch, T. Loulou, C. Davidson, and G. Savage: Metall. Mater. Trans. A, 2008, vol. 39A (4), pp. 853–64.

S.A. Metz and M.C. Flemings: AFS Trans., 1969, vol. 77, pp. 329–34.

Acknowledgments

The authors acknowledge the support from the CAST Cooperative Research Centre and the Australian Research Council’s Centre of Excellence for Design in Light Metals. The authors thank Dr. Y.H. Cho, The University of Queensland, for valuable discussions. One of the authors (SO) gratefully acknowledges the financial support provided by the Royal Thai Government and a Graduate School Research Travel Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 21, 2008.

Rights and permissions

About this article

Cite this article

Otarawanna, S., Gourlay, C.M., Laukli, H.I. et al. Microstructure Formation in AlSi4MgMn and AlMg5Si2Mn High-Pressure Die Castings. Metall Mater Trans A 40, 1645–1659 (2009). https://doi.org/10.1007/s11661-009-9841-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9841-1