Abstract

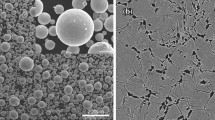

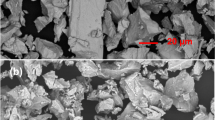

The Ti-6Al-4V (Ti-64) alloys modified with two levels of boron (1B and 1.7B (wt pct)) representing hypoeutectic and hypereutectic compositions, produced via a prealloyed powder metallurgy approach, were subjected to various standard heat treatments of Ti-64 to study the microstructural evolution and its influence on tensile properties. Boron-modified Ti-64 (Ti-64B) alloys exhibited differences in microstructural response to heat treatment compared to that of Ti-64 due to variations in constituent phase fractions and the influence of TiB on the beta-to-alpha phase transformation kinetics. The tensile elastic modulus of Ti-64B alloys increased nearly linearly with the boron content (or TiB volume fraction) and the increase could be satisfactorily predicted with an isostrain rule of mixtures (ROMs) and the Halpin–Tsai model. The Ti-64-1B possessed a good combination of tensile strength (1200 to1370 MPa) and ductility (10 to 13 pct), while Ti-64-1.7B exhibited high strength (1300 to 1695 MPa) and modest ductility (2 to 3.5 pct). Coarse primary TiB particles present in Ti-64-1.7B were found to initiate premature failure. Strength modeling revealed that load sharing by the micron-sized TiB whiskers provides the major contribution for the increase in yield strength.

Similar content being viewed by others

Notes

Adobe and Photoshop are the registered trademarks of Adobe Systems, Inc., San Jose, CA.

References

T.M. Godfrey, P.S. Goodwin, and C.M. Ward-Close: Adv. Eng. Mater., 2000, vol. 2, pp. 85–92.

A.E. Palty, H. Margolin, and J.P. Nielsen: Trans. ASM, 1954, vol. 46, pp. 312–28.

S. Tamirisakandala, R.B. Bhat, J.S. Tiley, and D.B. Miracle: Scripta Mater., 2005, vol. 53, pp. 1421–26.

J.L. Murray, P.K. Liao, and K.E. Spear: in Binary Alloy Phase Diagrams, 2nd ed., T.B. Massalski, ed., ASM International, Materials Park, OH, 1990, pp. 544–48.

O.M. Ivasishin, R.V. Teliovych, V.G. Ivanchenko, S. Tamirisakandala, and D.B. Miracle: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 402–16.

C.J. Boehlert, C.J. Cowen, S. Tamirisakandala, D.J. McEldowney, and D.B. Miracle: Scripta Mater., 2006, vol. 55, pp. 465–68.

Materials Property Handbook: Titanium Alloys, R. Boyer, G.E. Welsch, and E.W. Collins, eds., ASM International, Materials Park, OH, 1994, pp. 483–636.

D. Hill, R. Banerjee, D. Huber, J. Tiley, and H.L. Fraser: Scripta Mater., 2005, vol. 52, pp. 387–92.

S. Tamirisakandala, R.B. Bhat, D.B. Miracle, S. Boddapati, R. Bordia, R. Vanover, and V.K. Vasudevan: Scripta Mater., 2005, vol. 53, pp. 217–22.

S. Lieberman: Doctoral Dissertation, Georgia Institute of Technology, Atlanta, GA, 2007.

Metallic Materials Properties Development and Standardization (MMPDS-04), Battelle Memorial Institute, 2008, pp. 5–67.

S. Gorsse and D.B. Miracle: Acta Mater., 2003, vol. 51, pp. 2427–42.

J.C. Halpin and S.W. Tsai: Environmental Factors in Composite Design, AFML-TR-67-423, Air Force Materials Laboratory.

J.C. Halpin and J.L. Kardos: Polym. Eng. Sci., 1976, vol. 16, pp. 344–52.

C.J. Boehlert, S. Tamirisakandala, W.A. Curtin, and D.B. Miracle: Scripta Mater., 2009, vol. 61, pp. 245–48.

G. Bao, J.W. Hutchinson, and R.M. McMeeking: Acta Metall. Mater., 1991, vol. 39, pp. 1871–82.

D. Hull and D.J. Bacon: Introduction to Dislocations, 4th ed., Butterworth-Heinemann, Oxford, UK, 2001, pp. 219–23.

J.F. Nie: Scripta Mater., 2003, vol. 48, pp. 1009–15.

E.O. Hall: Proc. Phys. Soc., 1951, vol. B64, pp. 747–53.

B. Derby and P.M. Mummery: in Fundamentals of Metal Matrix Composites, S. Suresh, A. Moretensen, and A. Needleman, eds., Butterworth-Heinemann, Stoneham, MA, 1993, pp. 251–68.

Acknowledgments

This work was conducted as part of the in-house research on metallic materials with high structural efficiency at the U.S. Air Force Research Laboratory, Wright-Patterson AFB. One of the authors (DJM) was supported under the auspices of Air Force Contract No. F33615-02-2-5800 and a fellowship from the Dayton Area Graduate Studies Institute (DAGSI, Kettering, OH). The authors thank Fred Yolton (Crucible Research) for providing the Ti-64-1B powder and Dr. S. Lieberman (Georgia Institute of Technology, Atlanta, GA) for providing the stereological measurement data on TiB whiskers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 2, 2008.

Rights and permissions

About this article

Cite this article

McEldowney, D.J., Tamirisakandala, S. & Miracle, D.B. Heat-Treatment Effects on the Microstructure and Tensile Properties of Powder Metallurgy Ti-6Al-4V Alloys Modified with Boron. Metall Mater Trans A 41, 1003–1015 (2010). https://doi.org/10.1007/s11661-009-0157-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0157-y