Abstract

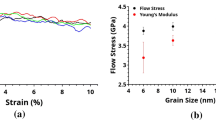

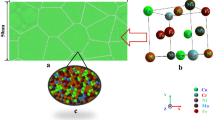

Large-scale molecular dynamics (MD) simulations are used to understand the macroscopic yield behavior of nanocrystalline Cu with an average grain size of 6 nm at high strain rates. The MD simulations at strain rates varying from 109 s−1 to 8 × 109 s−1 suggest an asymmetry in the flow stress values in tension and compression, with the nanocrystalline metal being stronger in compression than in tension. The tension-compression strength asymmetry is very small at 109 s−1, but increases with increasing strain rate. The calculated yield stresses and flow stresses under combined biaxial loading conditions (X-Y) gives a locus of points that can be described with a traditional ellipse. An asymmetry parameter is introduced that allows for the incorporation of the small tension-compression asymmetry. The biaxial yield surface (X-Y) is calculated for different values of stress in the Z direction, the superposition of which gives a full three-dimensional (3-D) yield surface. The 3-D yield surface shows a cylinder that is symmetric around the hydrostatic axis. These results suggest that a von Mises-type yield criterion can be used to understand the macroscopic deformation behavior of nanocrystalline Cu with a grain size in the inverse Hall–Petch regime at high strain rates.

Similar content being viewed by others

References

K.J. Hemker: Science, 2004, vol. 304, pp. 221–23.

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter: Nat. Mater., 2002, vol. 1, pp. 45–49.

V. Yamakov, D. Wolf, M. Salazar, S.R. Phillpot, and H. Gleiter: Acta Mater., 2001, vol. 49, pp. 2713–22.

H. Van Swygenhoven, M. Spaczer, and A. Caro: Acta Mater., 1999, vol. 47, pp. 3117–26.

H. Van Swygenhoven and P.M. Derlet: Phys. Rev. B, 2001, vol. 64, p. 224105.

P.M. Derlet and H. Van Swygenhoven: Scripta Mater., 2002, vol. 47, pp. 719–24.

A. Hasnaoui, H. Van Swygenhoven, and P.M. Derlet: Phys. Rev. B, 2002, vol. 66, p. 184112.

H. Van Swygenhoven, M. Spaczer, A. Caro, and D. Farkas: Phys. Rev. B, 1999, vol. 60, pp. 22–25.

D.W. Brenner: Computer Modeling of Nanostructured Materials, 2nd ed., Carl Koch, ed., Noyes Publications, Norwich, NY, 2006.

G.F. Dieter: Mechanical Metallurgy, 3rd ed., McGraw Hill, New York, NY, 1986.

H. Van Swygenhoven: Science, 2002, vol. 296, pp. 66–67.

J. Schiotz and K.W. Jacobsen: Science, 2003, vol. 301, pp. 1357–59.

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter: Philos. Mag. Lett., 2003, vol. 83, pp. 385–93.

K.S. Kumar, H. Van Swygenhoven, and S. Suresh: Acta Mater., 2003, vol. 51, pp. 5743–44.

D. Wolf, V. Yamakov, S.R. Phillpot, A. Mukherjee, and H. Gleiter: Acta Mater., 2005, vol. 53, pp. 1–40.

D. Jia, K.T. Ramesh, E. Ma, L. Lu, and K. Lu : Scripta Mater., 2001, vol. 45, pp. 613–20.

E.M. Bringa, A. Caro, Y. Wang, M. Victoria, J.M. McNaney, B.A. Remington, R.F. Smith, B.R. Torralva, and H. Van Swygenhoven: Science, 2005, vol. 309, pp. 1838–41.

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, 4th ed., Wiley & Sons, New York, NY, 1996.

T.H. Courtney: Mechanical Behavior of Materials, McGraw-Hill, New York, NY, 1990.

N.Q. Vo, R.S. Averback, P. Bellon, S. Odunuga, and A. Caro: Phys. Rev. B, 2008, vol. 77, p. 134108.

A.C. Lund, T.G. Nieh, and C.A. Schuh: Phys. Rev. B, 2004, vol. 69, p. 012101.

A.C. Lund and C.A. Schuh: Acta Mater., 2003, vol. 51, pp. 5399–5411.

C.A. Schuh and A.C. Lund: Nat. Mater., 2003, vol. 2, pp. 449–52.

A.C. Lund and C.A. Schuh: Acta Mater., 2005, vol. 53, pp. 3193–3205.

E. Moshe, S. Eliezer, E. Dekel, A. Ludmirsky, Z. Henis, M. Werdiger, I.B. Goldberg, N. Eliaz, and D. Eliezer: J. Appl. Phys., 1998, vol. 83, pp. 4004–11.

G.I. Kanel, S.V. Razorenov, A.V. Utkin, V.E. Fortov, K. Baumung, H.U. Karow, D. Rusch, and V. Licht: J. Appl. Phys., 1993, vol. 74, pp. 7162–65.

S. Eliezer, I. Gilath, and T. Bar-Noy: J. Appl. Phys., 1990, vol. 67, pp. 715–24.

H. Tamura, T. Kohama, K. Kondo, and M. Yoshida: J. Appl. Phys., 2001, vol. 89, pp. 3520–22.

E. Moshe, S. Eliezer, E. Dekel, Z. Henis, A. Ludmirsky, I.B. Goldberg, and D. Eliezer: J. Appl. Phys., 1999, vol. 86, pp. 4242–48.

P.M. Derlet and H. Van Swygenhoven: Phys. Rev. B, 2003, vol. 67, p. 014202.

S. Kumar, S.K. Kurtz, J.R. Banavar, and M.G. Sharma: J. Stat. Phys., 1992, vol. 67, pp. 523–51.

C.L. Kelchner, S.J. Plimpton, and J.C. Hamilton: Phys. Rev. B., 1998, vol. 58, pp. 11085–88.

A.F. Voter: in Intermetallic Compounds: Principles and Practice, J.H. Westbrook and R.L. Fleischer, eds., Wiley & Sons, New York, NY, 1994, vol. 1, p. 77.

J.A. Zimmerman, H. Gao, and F.F. Abraham: Modell. Simul. Mater. Sci. Eng., 2000, vol. 8, pp. 103–15.

Acknowledgment

The research is supported by the Army Research Office (ARO) through the National Research Council Research Associateship Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 1, 2009.

Rights and permissions

About this article

Cite this article

Dongare, A., Rajendran, A., Lamattina, B. et al. Atomic-Scale Study of Plastic-Yield Criterion in Nanocrystalline Cu at High Strain Rates. Metall Mater Trans A 41, 523–531 (2010). https://doi.org/10.1007/s11661-009-0113-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0113-x