Abstract

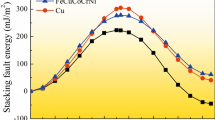

The evolution of deformation textures in copper and α brass that are representative of fcc metals with different stacking fault energies (SFEs) during cold rolling is predicted using a self-consistent (SC) model. The material parameters used for describing the micromechanical behavior of each metal are determined from the high-energy X-ray (HEXRD) diffraction data. At small reductions, a reliable prediction of the evolution of the grain orientation distribution that is represented as the continuous increase of the copper and brass components is achieved for both metals when compared with the experimental textures. With increasing deformation, the model could characterize the textures of copper, i.e., the strengthening of the copper component, when dislocation slip is still the dominant mechanism. For α brass at moderate and large reductions, a reliable prediction of its unique feature of texture evolution, i.e., the weakening of the copper component and the strengthening of the brass component, could only be achieved when proper boundary conditions together with some specified slip/twin systems are considered in the continuum micromechanics mainly containing twinning and shear banding. The present investigation suggests that for fcc metals with a low SFE, the mechanism of shear banding is the dominant contribution to the texture development at large deformations.

Similar content being viewed by others

Notes

LaboTex is a trademark of LaboSoft s.c., Krakow, Poland (developed by Labo Soft s.c.).

GSAS is a trademark of Los Alamos National Laboratory, Los Alamos, NM (developed by Allen C. Larsen & Robert B. Von Dree).

References

J. Hirsch and K. Lücke: Acta Metall., 1988, vol. 36, pp. 2863–82.

M. Mineur, P. Villechaise, and J. Mendez: Mater. Sci. Eng., A., 2000, vol. 286, pp. 257–68.

H. Paul, A. Morawiec, E. Bouzy, J.J. Fundenberger, and A. Piatkowski: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3775–86.

J. Hirsch, K. Lücke, and M. Hatherly: Acta Metall., 1988, vol. 36, pp. 2905–27.

T. Leffers and J.B. Bilde-Sørensen: Acta Metall. Mater., 1990, vol. 38, pp. 1917–26.

B. Clausen, T. Lorentzen, and T. Leffers: Acta Mater., 1998, vol. 46, pp. 3087–98.

S. Myagchilov and P.R. Dawson: Modell. Simul. Mater. Sci. Eng., 1999, vol. 7, pp. 975–1004.

A. Baczmański and C. Braham: Acta Mater., 2004, vol. 52, pp. 1133–42.

J.W. Hutchinson: Proc. R. Soc. London, 1976, vol. 348A, pp. 101–27.

B. Clausen, C.N. Tomé, D.W. Brown, and S.R. Agnew: Acta Mater., 2008, vol. 56, pp. 2456–68.

M.R. Daymond and H.G. Priesmeyer: Acta Mater., 2002, vol. 50, pp. 1613–26.

N. Jia, R.L. Peng, Y.D. Wang, S. Johansson, and P.K. Liaw: Acta Mater., 2008, vol. 56, pp. 782–93.

E.W. Huang, R.I. Barabash, N. Jia, Y.D. Wang, G.E. Ice, B. Clausen, J. Horton, and P.K. Liaw: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 3079–88.

B.J. Duggan, M. Hatherly, W.B. Hutchinson, and P.T. Wakefield: Met. Sci., 1978, vol. 12, pp. 343–51.

K. Pawlik and P. Ozga: LaboTex: The Texture Analysis Software, Göttinger Arbeiten zur Geologie und Paläontologie, SB4, 1999.

Y.D. Wang, R.L. Peng, J. Almer, M. Odén, Y.D. Liu, J.N. Deng, C.S. He, L. Chen, Q.L. Li, and L. Zuo: Adv Mater., 2005, vol. 17, pp. 1221–26.

A.C. Larson and R.B. Von Dreele: “General Structure Analysis System (GSAS),” Los Alamos National Laboratory Report LAUR 86-748, Los Alamos, NM, 2004.

J. Eshelby: Proc. R. Soc. London, 1957, vol. 241A, pp. 376–96.

J.W. Hutchinson: Proc. R. Soc. London, 1970, vol. 319A, pp. 247–72.

U.F. Kocks, C.N. Tomé, and H.R. Wenk: Texture and Anisotropy, Cambridge University Press, Cambridge, United Kingdom, 1998, pp. 347–52.

C.N. Tomé, P.J. Maudlin, R.A. Lebensohn, and G.C. Kaschner: Acta Mater., 2001, vol. 49, pp. 3085–96.

G. Proust, C.N. Tomé, and G.C. Kaschner: Acta Mater., 2007, vol. 55, pp. 2137–48.

G. Wassermann: Z. Metallkd., 1963, vol. 54, pp. 61–65.

H. Paul, J.H. Driver, C. Maurice, and Z. Jasieński: Mater. Sci. Eng., A., 2003, vol. 359, pp. 178–91.

J. Gil Sevillano, P. Van Houtte, and E. Aernoudt: Scripta Metall., 1977, vol. 11, pp. 581–55.

S.R. Kalidindi: Int. J. Plast., 2001, vol. 17, pp. 837–60.

Acknowledgments

This work is supported by the National Natural Science Foundation of China, Shenyang (Grant Nos. 50671022 and 50771026), the Program for Changjiang Scholars and Innovative Research Team in University (Grant No. IRT0713), and the key project supported by the National Ministry of Education of China. One of the authors (YDW) also acknowledges the financial support by the National Outstanding Young Scientist Investigation, Shenyang, Liaoning, China under Grant No. 50725102. This work has benefited from the use of the APS at the Argonne National Laboratory, Chicago, IL funded by the United States Department of Energy, Office of Science Laboratory, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given in the symposium “Neutron and X-Ray Studies of Advanced Materials,” which occurred February 15–19, 2009, during the TMS Annual Meeting in San Francisco, CA, under the auspices of TMS, TMS Structural Materials Division, TMS/ASM Mechanical Behavior of Materials Committee, TMS Advanced Characterization, Testing, and Simulation Committee, and TMS Titanium Committee.

Rights and permissions

About this article

Cite this article

Jia, N., Nie, Z., Ren, Y. et al. Formation of Deformation Textures in Face-Centered-Cubic Materials Studied by In-Situ High-Energy X-Ray Diffraction and Self-Consistent Model. Metall Mater Trans A 41, 1246–1254 (2010). https://doi.org/10.1007/s11661-009-0110-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0110-0