Abstract

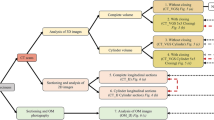

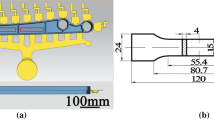

The nondestructive and three-dimensional quantitative evaluation of porosity in aluminum alloy die castings is proposed to identify whether the predominant cause of pore formation is shrinkage or entrapped gas. The validity of this method of evaluation was shown by comparing two different regions with different ratios of pores formed by shrinkage and gas. It was shown that the proposed evaluation can be used as a quantitative indication of porosity.

Similar content being viewed by others

References

E.J. Vinarcik: High Integrity Die Casting Process, John Wiley and Sons, New York, NY, 2003, pp. 7–10.

S.G. Lee, G.R. Patel, A.M. Gokhale, A. Sreeranganathan, and M.F. Horstemeyer: Scripta Mater., 2005, vol. 53, pp. 851–56.

J. Linder, A. Arvidsson, and J. Kron: Fatigue Fract. Eng. Mater. Struct., 2006, vol. 29, pp. 357–63.

P.T.E. Gebhard: Die Cast. Eng., 2003, vol. 47, pp. 54–56.

D.F. Allsop and D. Kennedy: Pressure Diecasting, Part 2: The Technology of the Casting and the Die, Pergamon Press, Ltd., New York, NY, 1983, pp. 6–7.

S. Kirkman: Shrinkage Porosity: A Guide to Correcting the Problems, North American Die Casting Association, Wheeling, IL, 2006, pp. 1–23.

W. Walkington: Gas Porosity: A Guide to Correcting the Problems, North American Die Casting Association, Wheeling, IL, 2006, pp. 1–21.

S.G. Lee and A.M. Gokhale: Scripta Mater., 2006, vol. 55, pp. 387–90.

D.L. Cocks: Die Cast. Eng., 1989, vol. 33, pp. 26–28.

A. Tewari, M. Dighe, and A.M. Gokhale: Mater. Characterization, 1998, vol. 40, pp. 119–32.

H. Patrick: Fonderie Fondeur Aujour’hui, 2007, vol. 265, pp. 12–25.

B.-T. Lee, S.-Z. Lu, and A. Hellawell: Cast Shop Technology, Proceedings of TMS Annual Meeting, 1997.

Y. Hangai and S. Kitahara: Mater. Trans., 2008, vol. 49, pp. 782–86.

Y. Hangai and S. Kitahara: Mater. Des., 2009, vol. 30, pp. 1169–73.

B. Mandelbrot: The Fractal Geometry of Nature, W H Freeman & Co., New York, 1982, pp. 1–468.

T. Sato, M. Matsuoka, and H. Takayasu: Fractals, 1996, vol. 4, pp. 463–68.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 28, 2009.

Rights and permissions

About this article

Cite this article

Hangai, Y., Maruhashi, S., Kitahara, S. et al. Nondestructive Quantitative Evaluation of Porosity Volume Distribution in Aluminum Alloy Die Castings by Fractal Analysis. Metall Mater Trans A 40, 2789–2793 (2009). https://doi.org/10.1007/s11661-009-0009-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0009-9