Abstract

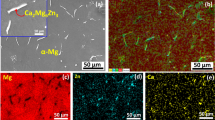

Iron-based surface composites were fabricated with Fe-based metamorphic alloy powders and VC powders by high-energy electron beam irradiation, and the correlation of their microstructure with hardness and fracture toughness was investigated. Mixtures of metamorphic powders and VC powders were deposited on a plain carbon steel substrate, and then the electron beam was irradiated on these powders without flux, to fabricate surface composites. The composite layers 1.3 to 1.8 mm in thickness contained a large amount (up to 47 vol pct) of hard Cr2B and V8C7 particles formed in eutectic colony regions and inside colonies, respectively. The hardness of the surface composites was approximately 2 to 4 times greater than that of the substrate because of Cr2B and V8C7 particles. According to the microfracture observation of the composite fabricated with mixing 30 wt pct VC powders, microcracks initiated at coarse V8C7 particles ins inside colonies as well as at Cr2B particles in colony regions, and were connected with other microcracks in a zigzag shape. Thus, it showed a higher fracture toughness and hardness twice as high as the composite fabricated without mixing VC powders.

Similar content being viewed by others

References

K. Euh, S. Lee, and K. Shin: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3143–51.

P. Jiang, X.L. He, X.X. Li, L.G. Yu, and H.M. Wang: Surf. Coat. Technol., 2000, vol. 130, pp. 24–28.

L.E. Rehn, S.T. Picraux, and H. Wiedersich: Surface Alloying by Ion, Electron, and Laser Beam, ASM INTERNATIONAL, Materials Park, OH, 1985, pp. 1–17.

A.P. Loureiro, O. Conde, L. Guerra-Rossa, and R. Vilar: Surface Engineering with High Energy Beams, Trans Tech Publications, Brookfield, VT,1990, pp. 1–13.

S. Schiller, U. Heisig, and S. Panzer: Electron Beam Technology, John Wiley & Sons, VEB Verlag Technik, Berlin, 1982, pp. 29–47.

E. Yun and S. Lee: Mater. Sci. Eng., A, 2005, vol. 405, pp. 163–72.

A. Basu, A.N. Samant, S.P. Harimkar, J.D. Majumdar, I. Manna, and N.B. Dahotre: Surf. Coat. Technol., 2008, vol. 202, pp. 2623–31.

D. Nam, J. Do, and S. Lee: Scripta Mater., 2009, vol. 60, pp. 695–98.

K.-H. Kim, S.-W. Lee, J.-P. Ahn, E. Fleury, Y.-C. Kim, and J.-C. Lee: Met. Mater. Int., 2007, vol. 13, pp. 21–24.

C.-M. Lee, S.-W. Chae, H.-J. Kim, and J.-C. Lee: Met. Mater. Int., 2007, vol. 13, pp. 191–96.

J.C. Oh, K. Euh, S. Lee, Y. Koo, and N.J. Kim: Scripta Mater., 1998, vol. 39, pp. 1389–94.

K. Lee, K. Euh, D.-H. Nam, S. Lee, and N.J. Kim: Mater. Sci. Eng., A, 2007, vols. A449–A451, pp. 937–40.

K.-W. Park, M. Wakeda, Y. Shibutani, E. Fleury, and J.-C. Lee: Met. Mater. Int., 2008, vol. 14, pp. 159–63.

C.C. Degnan and P.H. Shipway: Wear, 2002, vol. 252, pp. 832–41.

L. Davis: An Introduction to Welding Fluxes for Mild and Low Carbon Steels, TWI, Ablington Hall, Cambridge, United Kingdom, 1981, pp. 1–16.

S.K. Wu, H.C. Lin, and C.H. Yeh: Wear, 2000, vol. 244, pp. 85–93.

K. Lee, D.-H. Nam, S. Lee, and C.P. Kim: Mater. Sci. Eng., A, 2006, vol. 428, pp. 124–34.

T. Troczynski: Acta Mater., 1997, vol. 45, pp. 1445–54.

S.-J. Lee, B.-G. Yoo, J.-I. Jang, and J.-C. Lee: Met. Mater. Int., 2008, vol. 14, pp. 9–13.

H.J. Kim, S. Grossi, and Y.G. Kweon: Wear, (1999), vol. 232, pp. 51–60.

H.W. Jin, C.G. Park, and M.C. Kim: Scripta Mater., 1999, vol. 49, pp. 589–95.

K. Lee, D.-H. Nam, and S. Lee, and C.P. Kim: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1485–94.

M. Bauccio: ASM Engineered Materials Reference Book, 2nd ed., ASM INTERNATIONAL, Materials Park, OH, 1994, pp. 283–84.

S.N. Fadeev, M.G. Golkovski, A.I. Korchagin, A.V. Lavruhin, S.E. Petrov, R.A. Salimov, and A.F. Vaisman: Radiat. Phys. Chem., 2000, vol. 57, pp. 653–55.

G. Petzow: Metallographic Etching, ASM INTERNATIONAL, Metals Park, OH, 1976, p. 65.

J.C. Oh and S. Lee: Surf. Coat. Technol., 2004, vol. 179, pp. 340–48.

S. Lee, K.-S. Sohn, I. Park, and K. Cho: Met. Mater., 1995, vol. 1, pp. 37–46.

Y.-H. Kim, D. Kwon, and S. Lee: Acta Metall., 1994, vol. 42, pp. 1887–91.

“ASTM E399-83Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials,” Annual Book of ASTM Standards, ASTM INTERNATIONAL, Philadelphia, PA, 1997.

T. Tabata and R. Ito: Nucl. Sci. Eng., 1974, vol. 53, pp. 226–39.

J.C. Oh, D.-K. Choo, and S. Lee: Surf. Coat. Technol., 2000, vol. 127, pp. 76–85.

A.H. Ücisik and C. Bindal: Surf. Coat. Technol., 1997, vol. 94, pp. 561–65.

K. Euh and S. Lee: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 59–69.

S. Lee, S. Kim, B. Hwang, and C.G. Lee: Acta Mater., 2002, vol. 50, pp. 4755–62.

D. Suh, S. Lee, Y. Koo, and H.C. Lee: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3149–61.

D. Suh, S. Lee, S.-J. Kwon, and Y. Koo: Mater. Sci. Eng., A, 1998, vol. 248, pp. 245–55.

Acknowledgments

This work was supported by the National Research Laboratory Program (Grant No. ROA-2004-000-10361-0) funded by the Korea Science and Engineering Foundation (KOSEF), Daejeon, Korea. The authors are grateful to Drs. M.G. Golkovski and N. Kuksanov, Budker Institute of Nuclear Physics, and Dr. Kyuhong Lee, POSTECH, for their helpful discussion on the fabrication of the surface composites.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 31, 2008.

Rights and permissions

About this article

Cite this article

Nam, DH., Do, J. & Lee, S. Correlation of Microstructure, Hardness, and Fracture Toughness of Fe-Based Surface Composites Fabricated by High-Energy Electron Beam Irradiation with Fe-Based Metamorphic Alloy Powders and VC Powders. Metall Mater Trans A 40, 2959–2970 (2009). https://doi.org/10.1007/s11661-009-0004-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0004-1