Abstract

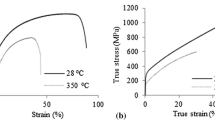

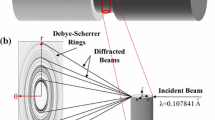

The deformation-induced martensite variant selection in a supermartensitic stainless steel (SMSS) has been examined in the temperature range from −60 °C to 150 °C, using in-situ tensile testing in combination with electron backscatter diffraction (EBSD) analyses in the scanning electron microscope (SEM). In the as-received (i.e., intercritically annealed) condition, the base material contains about 40 vol pct of retained austenite. At each testing temperature, this austenite transforms back to martensite during plastic deformation at a rate which is controlled by the accumulated plastic strain in the material. On the other hand, the applied strain rate and crystallographic orientations of the prior austenite grains do not affect the overall transformation rate. Moreover, the subsequent Schmid factor analysis reveals that the martensite variant selection is independent of the local slip activity within the austenite. Therefore, no new martensite variants, besides those already present in the parent steel, develop during the phase transformation. At the same time, their individual intensities remain approximately constant within each prior austenite grain. This means that the deformation-induced martensite variants nucleate from the same sites as those that are operative in the intercritically-annealed base material. Thus, the observed variant selection is another example of the inherent reversible nature of the martensite transformation.

Similar content being viewed by others

References

P.C. Maxwell, A. Goldberg, and J.C. Shyne: Metall. Trans., 1974, vol. 5, pp. 1319–24

G.B. Olson, and M. Cohen: Metall. Trans. A, 1982, vol. 13A, pp. 1907–14

P.J. Jacques, J. Landriere, and F. Delannay: Metall. Trans. A, 2001, vol. 32A, pp. 2759–67

S. Zaefferer, J. Ohlert, and W. Beck: Acta Mater., 2004, vol. 52, pp. 2765–78

M. Munherjee, O.N. Mohanty, S. Hashimoto, T. Hojo, and K. Sugimoto: ISIJ Int., 2006, vol. 46, pp. 316–24.

J.R. Patel, and M. Cohen: Acta Metall., 1953, vol. 1, pp. 531–38

P.C. Maxwell, A. Goldberg, and J.C. Shyne: Metall. Trans, 1974, vol. 5, pp. 1305–18

Y. Higo, F. Lecroisey, and T. Mori: Acta Metall., 1974, vol. 22, pp. 313–23

G.B. Olson, and M. Cohen: Metall. Trans. A, 1975, vol. 6A, pp. 791–95

M. Kato, and T. Mori: Acta Metall., 1976, vol. 24, pp. 853–60

L.E. Murr, K.P. Staudhammer, and S.S. Hecker: Metall. Trans. A, 1982, vol. 13A, pp. 627–35

N. Gey, B. Petit, and M. Humbert: Metall. Mater. Trans. A, 2006, vol. 36A, pp. 3291–99

S. Chatterjee, and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2007, vol. 23, pp. 1101–04

H.N. Han, C.G. Lee, D.-W. Suh, and S.-J. Kim: Mater. Sci. Eng. A, 2008, vol. 485, pp. 224–33

J.S. Bowles, and J.K MacKensize: Acta Metall., 1954, vol. 2, pp. 129–37.

J.K MacKensize, and J.S. Bowles: Acta Metall., 1954, vol. 2, pp. 138–47.

G. Kurdjomov, and G. Sachs: Z. Phys., 1930, vol. 64, pp. 325–43.

W.P. Liu, and H.J. Bunge: Mater. Lett., 1991, vol. 10, pp. 336–43

A.F. Gourgues-Lorenzon: Int. Mater. Rev., 2007, vol. 52, pp. 65–128

P. Bate, and B. Hutchinson: Acta Mater., 2000, vol. 48, pp. 3183–92.

S. Kundu, and H.K.D.H. Bhadeshia: Scripta Mater., 2006, vol. 55, pp. 779–81.

M. Butrón-Guillén, C. Costa Viana, and J. Jonas: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1755–68

N.J. Wittridge, J.J. Jonas, and J.H. Root: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 889–901

M. Karlsen, J. Hjelen, Ø. Grong, G. Rørvik, R. Chiron, U. Schubert, and E. Nilsen: Mater. Sci. Technol., 2008, vol. 24, pp. 64–72

G. Rørvik, S.M. Hesjevik, and S. Mollan: Stainless Steel World Conf. & Expo, Maastricht, The Netherlands, Nov. 8–10, 2005, paper no. 5089

O.M. Akselsen, G. Rørvik, P.E. Kvaale, and C.v.d. Eijk: Weld. J., 2004, May, pp. 160–67

J. Enerhaug: Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2002, pp. 3–14

E. Folkhard: Welding Metallurgy of Stainless Steels, Springer-Verlag, New York, NY, 1988, pp. 1–29

M. Munherjee, S.B. Singh, and O.N. Mohanty: Mater. Sci. Eng. A, 2006, vol. 20, pp. 319–22

P.D. Bilmes, M. Solari, and C.L. Llorente: Mater. Charact., 2001, vol. 46, pp. 285–96.

G. Sachs: Z. Verein D. Ing., 1928, vol. 72, p. 743

E. Schmid: Z. Elektrochem., 1931, vol. 37, p. 447.

G.I. Taylor: J. Inst. Met., 1938, vol. 62, pp. 307–27

E. Schmid, and W. Boas: Kristallplastizität, Springer Verlag, Berlin, 1935, pp. 1–349

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279–88.

J.D. Verhoeven: Fundamentals of Physical Metallurgy, John Wiley & Sons, New York, NY, 1975, pp. 493–94.

K. Bhattacharya, S. Conti, G. Zanzotto, and J. Zimmer: Nature, 2004, vol. 428, pp. 55–59.

H.K.D.H. Bhadeshia: J. Mater. Sci., 1982, vol. 17, pp. 383–86.

G.B. Olson, and M. Azrin: Metall. Trans. A, 1978, vol. 9A, pp. 713–21.

Acknowledgments

The authors acknowledge StatoilHydro and Norwegian University of Science and Technology (NTNU) for financial support and for providing access to the equipment and materials used in the microstructure examination. The authors are also grateful to Dr. Stephane Dumoulin (SINTEF–Materials and Chemistry) for developing the software used in the Schmid factor analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 14, 2008.

Rights and permissions

About this article

Cite this article

Karlsen, M., Grong, Ø., Søfferud, M. et al. Scanning Electron Microscopy/Electron Backscatter Diffraction–Based Observations of Martensite Variant Selection and Slip Plane Activity in Supermartensitic Stainless Steels during Plastic Deformation at Elevated, Ambient, and Subzero Temperatures. Metall Mater Trans A 40, 310–320 (2009). https://doi.org/10.1007/s11661-008-9729-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9729-5