Abstract

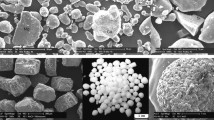

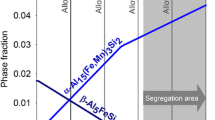

Lotus-type porous Al-Si (4, 8, 12, 14, and 18 wt pct) alloys were fabricated using the continuous casting technique under a hydrogen gas pressure of 0.1 MPa at various transference velocities, and the effects of the silicon content level and transference velocity on the pore morphology and porosity were investigated. Both the porosity and the average pore diameter increase as the silicon content level increases and decrease as the transference velocity increases. In particular, the velocity dependence is obviously exhibited at a silicon content level higher than 12 wt pct. The pore shape is changed from irregular in the higher-dendrite fraction to nearly circular in the lower-dendrite fraction. The porosity and the pore morphology are influenced by the silicon content level and transference velocity. In the model, these results can be understood with the explanation that the pores, which contribute to the increase in porosity, are generated at the eutectic fronts. This indicated that the porosity and the pore size in lotus-type porous Al-Si alloys can be well controlled by varying the silicon content level and the transference velocity.

Similar content being viewed by others

References

A.G. Evans, J.W. Hutchinson, M.F. Ashby: Prog. Mater Sci.., 1999, vol. 43, pp. 171–221

J. Banhart: Prog. Mater Sci.., 2001, vol. 46, pp. 559–632

V.I. Shapovalov: Mater. Sci. Forum, 1996, vols. 215–216, pp. 485–88

S. Yamamura, H. Shiota, K. Murakami, H. Nakajima: Mater. Sci. Eng., A, 2001, vol. 318, pp. 137–43

S.K. Hyun, H. Nakajima: Mater. Trans., 2002, vol. 43, pp. 526–31

T. Nakahata, H. Nakajima: Mater. Sci. Eng., A, 2004, vol. 384, pp. 373–76

S.K. Hyun, H. Nakajima: Mater. Lett., 2003, vol. 57, pp. 3149–54

T. Ikeda, T. Aoki, H. Nakajima: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 77–86

H. Nakajima: Prog. Mater. Sci., 2007, vol. 52, pp. 1091–1173

S.K. Hyun, K. Murakami, H. Nakajima: Mater. Sci. Eng., A, 2001, vol. 299, pp. 241–48

H. Nakajima: Mater. Trans., 2001, vol. 42, pp. 1827–29

S.K. Hyun, J.S. Park, M. Tane, and H. Nakajima: in Porous Metals and Metal Foaming Technology, H. Nakajima and N. Kanetake, eds., Japan Institute of Metals, Sendai, Japan, 2006, pp. 211–14

J.S. Park, S.K. Hyun, S. Suzuki, H. Nakajima: Acta Mater., 2007, vol. 55, pp. 5646–54

W.R. Opie, N.J. Grant: Trans. AIME, 1950, vol. 188, pp. 1237–41

Y. Shinada, Y. Ueda, S. Nishi: J. Jpn. Inst. Light Met., 1980, vol. 30, pp. 384–89

R.C. Atwood, S. Sridhar, W. Zhang, P.D. Lee: Acta Mater., 2000, vol. 48, pp. 405–17

P.D. Lee, J.D. Hunt: Acta Mater., 2001, vol. 49, pp. 1383–98

Y. Shinada, Y. Ueda, S. Nishi: J. Jpn. Inst. Light Met., 1983, vol. 33, pp. 508–17

R.C. Atwood, P.D. Lee: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 209–21

A.M. Samuel, F.H. Samuel: J. Mater. Sci., 1992, vol. 27, pp. 6533–63

A.K. Dahle, J. Taylor, D.A. Graham: Alum. Trans., 2000, vol. 3, pp. 17–29

H. Iwahori, K. Yonekura, Y. Yamamoto, M. Nakamura: AFS Trans., 1990, vol. 98, pp. 167–73

M. Ichimura, Y. Sasajima, M. Imabayashi: Mater. Trans., 1992, vol. 33, pp. 449–53

F.D. Manchester: Phase Diagrams of Binary Hydrogen Alloys, ASM INTERNATIONAL, Materials Park, OH, 2000, pp. 4 and 197

J.L. Murray, A.J. McAlister: Bull. Alloy Phase Diagrams, 1984, vol. 5, pp. 74–84

P.D. Lee, J.D. Hunt: Acta Mater., 1997, vol. 45, pp. 4155–69

Acknowledgments

The present work was supported by a Grant-in-Aid for the Creation of Innovations through Business-Academic-Public Sector Cooperation of the Ministry of Education, Culture, Sports, Science, and Technology of Japan. This work was also supported by the Global Century COE Program (Project: Center of Excellence for Advanced Structural and Functional Materials Design) from the Ministry of Education, Sports, Culture, Science, and Technology of Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 21, 2007.

Rights and permissions

About this article

Cite this article

Park, J., Hyun, S., Suzuki, S. et al. Fabrication of Lotus-Type Porous Al-Si Alloys Using the Continuous Casting Technique. Metall Mater Trans A 40, 406–414 (2009). https://doi.org/10.1007/s11661-008-9710-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9710-3