Abstract

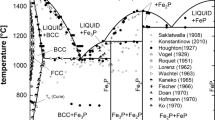

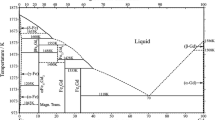

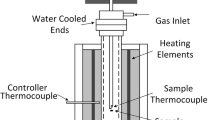

In the present study, the liquidus surface projection of the Fe-Nb-C system is proposed in the iron-rich corner using different techniques (differential thermal analysis (DTA), optical microscopy, scanning electron microscopy with energy dispersive X-ray analysis (EDX), and quantitative electron probe microanalysis (EPMA)). Thus, the primary crystallization phases, γ(Fe), δ(Fe), NbC1−x , and Fe2Nb, are identified. In addition, three invariant ternary reactions are proposed: two invariant eutectic ternary reactions: L ↔ δ(Fe) + Fe2Nb + NbC1−x and L ↔ γ(Fe) + NbC1−x + Fe3C; and a quasi-peritectic reaction: L + δ(Fe) ↔ γ(Fe) + NbC1−x as well as the univariant reactions in solid phase. However, the univariant line separating the primary crystallization surfaces δ(Fe) and NbC1−x goes through a maximum; the temperature is estimated in this work at 1456 °C < T < 1457 °C.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

Cameca is a trademark of Cameca, Courbevoie, France.

References

K. Hulka and J.R.C. Guimaräes: Technical Report, Companhia Brasileira de Metallurgia e Mineracao (CBMM), Av. Pres. Juscelino Kubitschek, São Paulo-SP, Brazil.

T. Carneiro and G. Trither: Superalloys of American Metals Market, Suppl., Aug. 24, 2000

Q. Yu, Z. Wang, X. Liu, G. Wang: Mater. Sci. Eng. A, 2004, vol. 379, pp. 384–90

H. Ohtani, M. Hasebe, T. Nishizawa: Calphad, 1989, vol. 13 (2), pp. 183–204

W. Hung: Z. Metallkd., 1990, vol. 81 (6), pp. 397–404

R.C. Das, R. Jha, T. Mukherjee: J. Alloy Phase Diagrams, 1986, vol. 2 (2), pp. 131–40

J.L. Pouchou, F. Pichoir: J. Microsc. Electron., 1986, vol. 11 (4), pp. 229–50

S.E. Amara, R. Kesri, N. Valignat, S. Hamar-Thibault: Mikrochimica Acta, 1994, vols. 114–115 (12), pp. 157–64

F. Haddad, S.E. Amara, R. Kesri, S. Hamar-Thibault: J. Phys. IV France, 2004, vol. 122, pp. 35–39

M. Hansen, K. Anderko: Constitution of Binary Alloys, 2nd ed., McGraw-Hill, New York, NY, 1958

E. Rudy, S.T. Winisch, C.E. Brukel: Planseeberichte Pulvermetallurgie, 1968, vol. 16, pp. 3–33

J.P. Guha, D. Kolar: J. Less-Common Met., 1972, vol. 29, pp. 33–40

M.A. Mangan, M.V. Kral, G. Spanos: Acta Mater., 1999, vol. 47 (17), pp. 4263–74

M.V. Kral, R.W. Fonda: Scripta Mater., 2000, vol. 43, pp. 193–98

C.-Y. Hung, G. Spanos, R.O. Rosenberg, M.V. Kral: Acta Mater., 2002, vol. 50, pp. 3781–88

N.E. Hannerz, U. Lindborg, B. Lehtinen: J. Iron Steel Inst., 1968, vol. 206, pp. 68–73

S.E. Amara, R. Kesri, S. Hamar-Thibault: Z. Metallkd., 2000, vol. 91 (12), pp. 1020–25

S.E. Amara: Ph.D. Thesis, University of Science and Technology, Houari Boumediene, Algeria, 1999

V.G. Rivlin: Int. Met. Rev., 1984, vol. 29 (2), pp. 96–120

S.E. Amara, A. Belhadj, R. Kesri, S. Hamar-Thibault: Z. Metallkd., 1999, vol. 90 (2), pp. 116–23

Acknowledgments

The authors express their gratitude to S. Hamar-Thibault (retired Chargée de Recherche) for her help with the microprobe analysis (Laboratoire de Thermodynamique et Physico-Chimie Métallurgiques ENSEEG, Domaine Universitaire, Saint-Martin- d’Hères Cedex, France) of some alloys.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 7, 2007.

Rights and permissions

About this article

Cite this article

Haddad, F., Amara, S.E. & Kesri, R. Liquidus Surface Projection of the Fe-Nb-C System in the Iron-Rich Corner. Metall Mater Trans A 39, 1026–1033 (2008). https://doi.org/10.1007/s11661-008-9483-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9483-8