Abstract

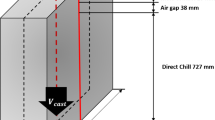

An analysis of published experimental and numerical results shows that there is a scaling relationship between the magnitude and direction of centerline segregation in direct-chill (DC) cast billets from aluminum alloys and the process parameters, i.e., billet diameter and casting speed. It seems that there is always a range of these process parameters where the centerline segregation is positive, and there is a threshold when the centerline segregation vanishes. Numerical simulations of macrosegregation during DC casting of a binary Al-Cu alloy were performed at different ratios of casting speed and billet diameter. The macrosegregation model takes into account only two mechanisms of macrosegregation, i.e., thermosolutal convection and shrinkage-induced flow. The results of these computer simulations fit well to the dependence obtained using numerous reference data. The results are discussed in terms of the contribution of different mechanisms of macrosegregation and the shape of the billet sump.

Similar content being viewed by others

References

R. Nadella, D.G. Eskin, Q. Du, and L. Katgerman: Progr. Mater. Sci., 2008, vol. 53, pp. 421–80

C. Beckermann: Int. Mater. Rev., 2002, vol. 47, pp. 243–61

V.A. Livanov, R.M. Gabidullin, V.S. Shipilov: Continuous Casting of Aluminum Alloys, Metallurgiya, Moscow, 1977, pp. 98–110

H. Yu and D.A. Granger: Proc. Int. Conf. Aluminum Alloys—Physical and Mechanical Properties, E.A. Starke and T.H. Sanders, eds., EMAS, Warley, United Kingdom, 1986, pp. 17–29

T.L. Finn, M.G. Chu, W.D. Bennon: in Micro/Macro Scale Phenomena in Solidification, C. Beckermann, ed., ASME, New York, NY, 1992, pp. 17–26

A.V. Reddy, C. Beckermann: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 479–89

Q. Du, D.G. Eskin, L. Katgerman: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 180–86

V.I. Dobatkin: Continuous Casting and Casting Properties of Alloys, Oborongiz, Moscow, 1948, pp. 139–46

N.F. Anoshkin, V.I. Dobatkin: Mater. Sci. Eng. A, 1999, vol. 263, pp. 224–29

W.D. Bennon, F.P. Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2161–70

P.J. Prescott, F.P. Incropera: Int. J. Heat Mass Transfer, 1991, vol. 34, pp. 2351–59

M. Založnik, B. Šarler: Mater. Sci. Eng. A, 2005, vols. 413–414, pp. 85–91

M. Založnik, B. Šarler, D. Gobin: Mater. Technol., 2004, vol. 38, pp. 249–55

C.J. Vreeman, F.P. Incropera: Int. J. Heat Mass Transfer, 2000, vol. 43, pp. 687–704

C.J. Vreeman, J.D. Scholz, M.J.M. Krane: J. Heat Transfer, 2002, vol. 124, pp. 947–53.

G. Lesoult, V. Albert, B. Appolaire, H. Combeau, D. Daloz, A. Joly, C. Stomp, G.-U. Gruen, P. Jarry: Sci. Technol. Adv. Mater., 2001, vol. 2, pp. 285–91

B. Venneker, L. Katgerman: in Light Metals 2001, J.L. Anjier, ed., TMS, Warrendale, PA, 2001, pp. 823–29

L. Katgerman, B. Venneker, J. Zuidema: in Light Metals 2003, P. Crepeau, ed., TMS, Warrendale, PA, 2003, pp. 815–20

D.G. Eskin, J. Zuidema, V.I. Savran, L. Katgerman: Mater. Sci. Eng. A, 2004, vol. 384, pp. 232–44

M.G. Chu, J.E. Jacoby: in Light Metals 1990, C.M. Bickert, ed., TMS, Warrendale, PA, 1990, pp. 925–30

D.G. Eskin, Q. Du, L. Katgerman: Scripta Mater., 2006, vol. 55, pp. 715–18.

Acknowledgment

The article is written within the framework of the research program of the Netherlands Institute for Metals Research (www.nimr.nl), Project No. MC 4.02134.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 7, 2007.

Rights and permissions

About this article

Cite this article

Eskin, D., Du, Q. & Katgerman, L. Scale Rules for Macrosegregation during Direct-Chill Casting of Aluminum Alloys. Metall Mater Trans A 39, 1206–1212 (2008). https://doi.org/10.1007/s11661-008-9468-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9468-7