Abstract

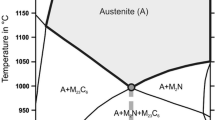

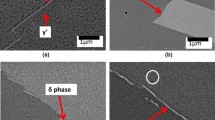

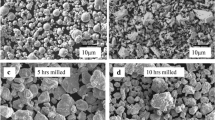

The mechanical properties of Ni-containing powder metal (PM) steels are usually inferior to those of their wrought counterparts. The main problem is attributed to the non-uniform Ni distribution, in addition to the problems caused by porosity. The effects of this non-uniform alloying on the mechanical properties were investigated in this study using mini tensile bars that were made of diffusion-alloyed FD-0405 (Fe-4Ni-1.5Cu-0.5Mo-0.5C) powders. In-situ observations under a scanning electron microscope (SEM) were carried out during the tensile testing. The results indicated that the soft Ni-rich/C-lean area around the pore, which was identified as ferrite using electron backscattered diffraction (EBSD) analysis, was responsible for the failures. By adding Cr in the form of prealloyed powders, the distribution of Ni and C became more uniform, and the Ni-rich/C-lean ferrite was replaced by bainite and martensite. After sintering at 1250 °C for 1 hour, the tensile strength of the Fe-4Ni-1.5Cr-0.2Mo-0.5C and Fe-4Ni-3Cr-0.5Mo-0.5C reached 1178 and 1323 MPa, respectively, without employing any accelerated cooling system. These properties are higher than all those reported to date in the literature for sinter-hardened PM alloys that were rapidly cooled after sintering. This significant improvement was attributed to the homogeneous alloying, particularly due to the reduction of the repelling effect between Ni and C, as was explained through the thermodynamics analysis using the Thermo-Calc program.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

F. Thümmler and R. Oberacker: Introduction to PM, The Institute of Materials, London, UK, 1993, pp. 255–58

N. Chawla, X. Deng: Mater. Sci. Eng., 2005, vol. 390A, pp. 98–112

W.A. Spitzig, R.E. Semlser, O. Richmond: Acta Metall., 1988, vol. 36 (5), pp. 1201–11

R.J. Bourcier, D.A. Koss, R.E. Smelser, O. Richmond: Acta Metall., 1986, vol. 34 (12), pp. 2443–53

K.M. Vedula, R.W. Heckel: in Modem Developments in Powder Metallurgy, H.H. Hausner, H.W. Antes, G.D. Smith, eds., Metal Powder Industries Federation, Princeton, NJ, 1981, vol. 12, pp. 759–77

T. Marcu, A. Molinari, G. Straffelini, S. Berg: Powder Metall., 2005, vol. 48 (2), pp. 139–43

M. Hanada, N. Motooka, and T. Honda: Advances in Powder Metallurgy and Particulate Materials, compiled by J.M. Capus and R.M. German, MPIF, Princeton, NJ, 1992, vol. 5, pp. 215–26

R. J. Causton: Advances in Powder Metallurgy and Particulate Materials, compiled by T.M. Cadle and K.S. Narasimhan, MPIF, Princeton, NJ, 1996, vol. 4, part 13, pp. 391–412

M. Khaleghi, R. Haynes: Powder Metall., 1985, vol. 28 (4), pp. 217–23

Materials Standards for P/M Structural Parts, Metal Powder Industries Federation, Princeton, NJ, 2003, pp. 42–49

M.W. Wu, K.S. Hwang, H.S. Huang, K.S. Narasimhan: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2559–68

S. Carabajar, C. Verdu, R. Fougeres: Mater. Sci. Eng., 1997, vol. 232A, pp. 80–87

N. Chawla, T.F. Murphy, K.S. Narasimhan, M. Koopman, K.K. Chawla: Mater. Sci. Eng., 2001, vol. 308A, pp. 180–88

E. Dudrova, M. Kabatova, M. Kupkova: Kov. Mater. 2002, vol. 40, pp. 24–33

S.J. Polasik, J.J. Williams, N. Chawla: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 73–81

S. Carabajar, C. Verdu, A. Hamel, R. Fougeres: Mater. Sci. Eng., 1998, vol. 257A, pp. 225–34

N. Chawla, S. Polasik, K.S. Narasimhan, T. Murphy, M. Koopman, K.K. Chawla: Int. J. Powder Metall., 2001, vol. 37 (3), pp. 49–57

B.A. Gething, D.F. Heaney, D.A. Koss, T.J. Mueller: Mater. Sci. Eng., 2005, vol. 390A, pp. 19–26

Z.R. He, G.X. Lin, H.A. Chen: Mater. Sci. Eng., 2001, vols. 319A–321A, pp. 312–15

M. Dollar, I.M. Bernstein, A.W. Thompson: Acta Metall., 1988, vol. 36 (2), pp. 311–20

M.W. Wu, K.S. Hwang: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 3577–85

S.T. Campbell, T. Singh, and T.F. Stephenson: Advances in Powder Metallurgy and Particulate Materials, compiled by W.B. James and R.A. Chernenkoff, MPIF, Princeton, NJ, 2004, part 7, pp. 105–15

H. Danninger, D. Spoljaric, B. Weiss: Int. J. Powder Metall., 1997, vol. 33 (4), pp. 43–53

W.F. Smith: Structure and Properties of Engineering Alloys, 2nd ed., McGraw-Hill Co., New York, NY, 1993, pp. 136–37

A. Moser, A. Legat: Hart. Techn. Mitt., 1969, vol. 24 (2), pp. 100–05.

Acknowledgment

The authors thank the Lenco Co. and the National Science Council for their support of this project, under Contract No. NSC 94-2622-E-002-008-CC3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 11, 2006

Rights and permissions

About this article

Cite this article

Wu, M.W., Hwang, K.S. & Huang, H.S. In-Situ Observations on the Fracture Mechanism of Diffusion-Alloyed Ni-Containing Powder Metal Steels and a Proposed Method for Tensile Strength Improvement. Metall Mater Trans A 38, 1598–1607 (2007). https://doi.org/10.1007/s11661-007-9201-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9201-y