Abstract

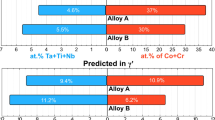

The local grain boundary (GB) curvature in a model Ni-based superalloy was measured experimentally using Dehoff’s tangent count method. The results show that, in materials containing significant amounts of second-phase particles, the curvature parameter, κ, which relates the mean local curvature to the grain size, can adopt far lower values than have been reported previously. It is also shown that the value of κ is not a constant, as is usually assumed, but instead varies both with the volume fraction of second-phase particles and with the holding time during high-temperature annealing. The lowest values for κ were obtained for high particle volume fractions and long annealing times. Because the local boundary curvature constitutes the driving force for grain growth, these observations could help to explain grain growth phenomena in heavily pinned systems.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electronic Optics Ltd., Tokyo.

References

R.T. DeHoff: Trans. AIME, 1967, vol. 239, pp. 617-21

J.W. Cahn: Trans. AIME, 1967, vol. 239, pp. 610–16

R.T. DeHoff: Microstructural Science, American Elsevier Pub., New York, NY, 1977, vol. 5, pp. 331–43

J.P. Nielsen, L.P. Stone: The Nature and Behavior of Grain Boundaries, Plenum Press, New York, NY, 1972, pp. 229–32

B.R. Patterson, Y. Liu: Metall. Trans. A, 1992, vol. 23A, pp. 2481–82

P.R. Rios, G.S. Fonseca: Scripta Mater., 2004, vol. 50, pp. 1373–77

P.R. Rios, G.S. Fonseca: Scripta Mater., 2005, vol. 52, pp. 893–97

C.H. Wörner: Scripta Metall., 1989, vol. 23, pp. 1909–12

N.A. Haroun, D.W. Budworth: J. Mater. Sci., 1968, vol. 3, pp. 326–28

W.W. Milligan, E.L. Orth, J.J. Schirra, M.F. Savage: Superalloys 2004, TMS, Warrendale, PA, 2004, pp. 331–39

K. Song: Ph.D. Thesis, University of Connecticut, Storrs, CT, 2005

A.M. Wusatowska-Sarnek, M.J. Blackburn, M. Aindow: Mater. Sci. Eng. A, 2003, vol. 360A, pp. 390–95

M. Soucail, R. Messina, A. Cosnuau, L.P. Kubin: Mater. Sci. Eng. A, 1999, vol. 271A, pp. 1–7

D.J. Srolovitz, M.P. Anderson, G.S. Grest, P.S. Sahni: Acta Metall., 1984, vol. 32, pp. 1429–37

M. Hillert: Acta Metall., 1988, vol. 36, pp. 3177–81

R.D. Doherty, K. Li, M.P. Anderson: Grain Growth in Polycrystalline Materials III, TMS, Warrendale, PA, 1998. pp. 271–76

Acknowledgments

This work was supported by DARPA/USAF under Contract No F33615-00-2-5216, with Dr. R. Dutton as technical monitor. The authors thank Dr. Mike Savage, Pratt and Whitney, for providing the alloys used in this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, K., Aindow, M. Grain Boundary Curvature in a Model Ni-Based Superalloy. Metall Mater Trans A 38, 1–6 (2007). https://doi.org/10.1007/s11661-006-9032-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-9032-2