Abstract

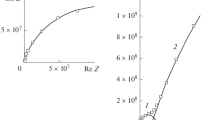

It has been observed that the wettability/surface energy of polycarbonate (PC) changes with the variation in process parameters, such as discharge power and time of exposure of DC glow discharge. The wettability of the PC surface has been measured by the contact angle measurements of two test liquids, such as water and formamide, by the sessile drop method. The lap shear tensile strength (LSTS) of PC to the mild steel (MS) adhesive joint has been measured with both the as-received polymer and those exposed under DC glow discharge. An appreciable increase in the LSTS has been attained for samples treated under DC glow discharge at a lower power level and also at a short exposure time at higher power. This increase in LSTS is attributed to increased polar surface energy with increasing power and time of exposure. After a certain level of surface modification of the PC, the strength of the adhesive joint deteriorates, while the total surface energy and its polar component may increase continuously. The subsurface damage taking place particularly at long exposure times and at higher power may lead to deterioration of LSTS in spite of a strong interface between the polymer and the adhesive. In such a case, the joint is observed to fracture not across the interface but through the subsurface. The optimum exposure limits the subsurface damage while creating a strong interface.

Similar content being viewed by others

References

Seidel C., Kopf H., Gotsmann B., Vieth T., Reihs K., Fuchs H. (1999) Appl. Surface Sci., 150:19

Vallon S., Hofrichter A., Guyot L., Drevillon B., Klemberg-Sapieha J.E., Martinu L., Poncin-Epaillard F. (1996) J. Adhes. Sci. Technol., 10:1287

Zajickova L., Subedi D.P., Bursikova V., Veltruska K. (2003) Acta Physica Slovaca 53:489

Gil’man A.B., Vengerskaya L.E., Grigoreva G.A., Potapov V.K. (1999) High Energy Chem., 33:467

Liston E.M., Martinu L., Wertheimer M.R. (1993) J. Adhes. Sci. Technol., 7:1077

D.K. Owens and R.C. Wendt (1969) J. Appl. Polymer. Sci., 13:1741

Panwar A.K., Barthwal S.K., Ray S. (2003) J. Adhes. Sci. Technol., 17:1321

S.K. Barthwal, A.K. Panwar, and S. Ray: in Contact Angle, Wettability and Adhesion, K.L. Mittal, ed., 2003, vol. 03, p. 175

A.K. Panwar, S.K. Barthwal, and S. Ray: unpublished research

Kell S.O., Henshaw T., Farrow G., Aindow M., Jones C. (1995) Surf. Interface Analysis 23:319

Carlsson C.M.G., Johanson K.S. (1993) Surf Interface Analysis 20:441

Petasch W., Rauchle E., Walker M., Elsner P. (1995) Surf. Coating Technol., 74–75:682

Guezenoc H., Segul S., Thery S., Asfardjani K. (1993) J. Adhes. Sci. Technol., 7:953

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Panwar, A.K., Barthwal, S.K. & Ray, S. Variation of Lap Shear Tensile Strength of Polycarbonate–Mild Steel Adhesive Joints with DC Glow Discharge Modified Polycarbonate. Metall Mater Trans A 38, 197–202 (2007). https://doi.org/10.1007/s11661-006-9001-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-9001-9