Abstract

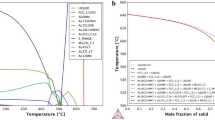

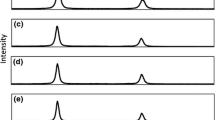

Two nickel (Ni)-coated aluminum (AI) powders were consolidated to full or near-full density by using the equal-channel angular extrusion (ECAE) technique. Mixtures (in at. pct) of 78Al-22Ni (63Al-37Ni in wt pct), hereafter termed Al-22Ni, and of 39Al-61Ni (23Al-77Ni in wt pct), hereafter termed Al-61Ni, were placed in square-shaped copper (Cu) or Ni casings, sealed, and heated to a uniform temperature. Subsequently, the billets were dropped into the ECAE die and were single-pass extruded. Preheating temperatures ranged from ambient temperature to 700 °C. Scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), and microhardness measurements were used to examine the resultant intermetallics. The onset and nature of the transformation from the precursors into the products were further studied by differential thermal analysis. It was found that the preheating temperature affected the transformation of the Ni-coated Al powder into a nickel-aluminide intermetallic. Specifically, samples of Al-22Ni and Al-61Ni, preheated and consolidated below the nominal reaction temperature of Ni and Al, consisted of a cellular Al structure interposed with a Ni boundary layer. The samples preheated and consolidated above this temperature consisted of Al3Ni and Al3Ni2, AlNi, and AlNi3, respectively. In this case, ECAE caused the multiphase structure of the intermetallics to homogenize and disperse; this was more so for 78Al-22Ni than for 39Al-61Ni. It was also found that the use of a Ni vs Cu casing material greatly improved the densification of the powders. Unlike that found with the Cu casing, full densification using a Ni casing was achieved in a single pass.

Similar content being viewed by others

References

K. Morsi: Mater. Sci. Eng. A, 2001, vol. A199, pp. 1–15.

T. Cheng and M. McLean: Mater. Lett., 1996, vol. 29, pp. 91–99.

S.C. Deevi and V.K. Sikka: Intermet, 1997, vol. 5, pp. 17–27.

Z.G. Liu, J.T. Guo, and Z.Q. Hu: Mater. Sci. Eng. A, 1995, vols. A192–A193, pp. 577–82.

F. Cardellini, G. Mazzone, and M.V. Antisari: Acta Mater, 1996, vol. 44, pp. 1511–17.

O. Abe and A. Tsuge: J. Mater. Res., 1991, vol. 6, pp. 928–34.

K.A. Philpot, Z.A. Munir, and J.B. Holt: J. Mater. Sci., 1987, vol. 22, pp. 159–69.

D.E. Alman: J. Mater. Sci. Lett., 1994, vol. 13, pp. 483–86.

J.P. Lebrat, A. Varma, and P.J. McGinn: J. Mater. Res., 1994, vol. 9, pp. 1184–92.

H.P. Li and J.A. Sekhar: J. Mater. Res., 1995, vol. 10, pp. 2471–80.

L. Plazanet and F. Nardou: J. Mater. Sci., 1998, vol. 33, pp. 2129–36.

Q. Fan, H. Chai, and Z. Jin: Intermet, 2001, vol. 9, pp. 609–19.

Y. Horie, R.A. Graham, and I.K. Simonsen: Metallurgical Applications of Shock-Wave and High-Strain-Rate Phenomena, Marcel Dekker Inc., New York, NY, 1986, pp. 1023–35.

I. Song and N.N. Thadhani: Metall. Mater. Trans. A, 1992, vol. 23A, pp. 41–48.

N.N. Thadhani, S. Work, R.A. Graham, and W.F. Hammetter: J. Mater. Res., 1992, vol. 7, pp. 1063–75.

E. Dunbar, N.N. Thadhani, and R.A. Graham: J. Mater. Sci., 1993, vol. 28, pp. 2903–14.

T. Aizawa: Ceram. Eng. Sci. Proc., 1997, vol. 18, pp. 573–80.

L.J. Kecskes, S.T. Szewczyk, A.B. Peikrishvili, and N.M. Chihkradze, Metall. Mater. Trans. A, 2004, vol. 35, pp. 1125–31.

Binary Alloy Phase Diagrams, 2nd ed., T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, eds., William W. Scott Publishers, New York, NY, 1990, pp. 181–84.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kecskes, L.J., Woodman, R.H., Barber, R.E. et al. Severe plastic deformation of nickel-coated aluminum precursor powders at elevated temperatures. Metall Mater Trans A 37, 449–457 (2006). https://doi.org/10.1007/s11661-006-0016-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-0016-z