Abstract

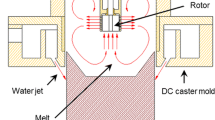

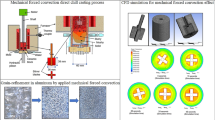

A thorough experimental investigation of the effects of melt temperature and casting speed on the structure and defect formation during the steady and nonsteady stages of direct-chill (DC) casting of an Al-2.8 pct Cu alloy is performed. In addition, the temperature and melt-flow distributions in the sump of billets cast at different melt temperatures are numerically simulated and used in the discussion on the experimental results. Apart from already known phenomena such as the coarsening of the structure, deepening of the sump, and increased probability of bleed-outs during DC casting with increased casting temperature, a few new observations are made. The increased melt temperature is shown to increase the severity of subsurface segregation, whereas the macrosegregation in the rest of the billet remains virtually unaffected. Hot-tearing susceptibility is strongly diminished by an increased melt superheat. The amount and distribution of “floating” grains is demonstrated to depend on both the melt temperature and the casting speed. The porosity was found to only slightly depend on the melt temperature. The amount of nonequilibrium eutectic in the center of the billet increases with increasing melt temperature. The effects of melt temperature on the dimensions of the sump, transition region, and mushy zone and on the melt-flow pattern in the sump are discussed and used in the interpretation of experimentally observed phenomena.

Similar content being viewed by others

References

E.F. Emley: Int. Met. Rev., 1976, June, review 206, pp. 75–115.

J.F. Grandfield and P.T. McGlade: Mater. Forum, 1996, vol. 20, pp. 29–51.

D.G. Eskin, Suyitno, V.I. Savran, and L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3551–61.

D.G. Eskin, J. Zuidema, Jr., V.I. Savran, and L. Katgerman: Mater. Sci. Eng. A, 2004, vol. 384, pp. 232–44.

G.U. Grün and W. Schneider: in Light Metals 1997, R. Huglen, ed., TMS, Warrendale, PA, 1997, pp. 1059–64.

E.D. Tarapore: in Light Metals 1989, P.G. Campbell, ed., TMS, Warrendale, PA, 1989, pp. 875–80.

J.M. Reese: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 491–99.

A.D. Shestakov, I. Ross, and A. Nauk: Metally, 1996, No. 6, pp. 130–38.

V.I. Dobatkin, A.D. Shestakov, I. Ross, and A. Nauk: Metally, 1992, No. 4, pp. 55–60.

N.A. El-Mahalawy and A.M. Assar: J. Mater. Sci., 1991, vol. 26, pp. 1729–33.

N.A. El-Mahallawy, M.A. Taha, A.M. Assar, and R.M. Hamouda: Mater. Sci. Technol., 1993, vol. 9, pp. 691–97.

M.A. Taha, N.A. El-Mahallawy, and Hamouda: Mater. Design, 2002, vol. 23, pp. 195–200.

I.L. Ferreira, C.A. Santos, V.R. Voller, and A. Garcia: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 285–97.

D.A. Weirauch, Jr., L. Martonik, A. Giron, D. Ziegler, and M. Chu: in Light Metals 2000, R.D. Peterson, ed., TMS, Warrendale, PA, 2000, pp. 649–55.

D.C. Weckman and P. Niessen: Z. Metallkd., 1984, vol. 75, pp. 332–40.

J.A. Spittle and A.A. Cushway: Met. Technol., 1983, vol. 10, pp. 6–13.

D.G. Eskin: Z. Metallkd., 1996, vol. 87, pp. 295–99.

D.G. Eskin: Mater. Sci. Forum, 2000, vols. 331–337, part 1, pp. 155–60.

W. Jie, Z. Chen, W. Reif, and K. Müller: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 799–805.

W.I. Pumphrey and J.V. Lyons: J. Inst. Met., 1947, vol. 74, pp. 439–55.

J. Zuidema, Jr., and L. Katgerman: in Modelling of Casting, Welding and Advanced Solidification Processes IX, P.R. Sahm, P.N. Hansen, and J.G. Conley, eds., Shaker-Verlag, Aachen, 2000, pp. 789–96.

J. Zuidema, Jr., L. Katgerman, I.J. Opstelten, and J.M. Rabenberg: in Light Metals 2001, J.L. Anjier, ed., TMS, Warrendale, PA, pp. 873–78.

FLOW-3D User’s Manual, version 8.1, Flow Science, Inc., Santa Fe, NM.

L. Arnberg, L. Backerud, and G. Chai: Solidification Characteristics of Aluminum Alloys. Vol. 3: Dendrite Coherency, American Foundrymen Society, Des Plaines, IL, 1996.

V.A. Livanov, R.M. Gabidullin, and V.S. Shepilov: Metallurgiya, Moscow, 1977.

B. Commet, P. Delaire, J. Rebenberg, and J. Storm: in Light Metals 2003, P.N. Crepeau, ed., TMS, Warrendale, PA, 2003, pp. 711–17.

D.G. Eskin, Suyitno, and L. Katgerman: Progr. Mater. Sci., 2004, vol. 49, pp. 629–711.

J.M. Drezet and M. Rappaz: in Light Metals 2001, J.L. Anjier, ed., TMS, Warrendale, PA, 2001, pp. 887–93.

D.G. Eskin, Suyitno, J.F. Mooney, and L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1325–35.

Author information

Authors and Affiliations

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s11661-005-0132-1.

Rights and permissions

About this article

Cite this article

Eskin, D.G., Savran, V.I. & Katgerman, L. Effects of melt temperature and casting speed on the structure and defect formation during direct-chill casting of an Al-Cu alloy. Metall Mater Trans A 36, 1965–1976 (2005). https://doi.org/10.1007/s11661-005-0059-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0059-6