Abstract

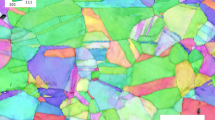

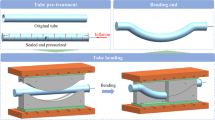

The analysis and modeling of tube-hydroformed components is more complicated than that employed for sheet-metal panels, due to the lengthier process sequence and variable strain path—from flat-rolled sheet to tube; from straight tube to bent tube; and from bent tube to hydroformed component. These additional process steps make it difficult to determine whether post mortem analyses of tube failure during hydroforming can, and should, be conducted with the same tools and databases as used for simple stampings. To provide a partial answer, the properties of commercially fabricated welded straight tubes were evaluated using a free-expansion internal pressure test and compared with those of free-expansion internal pressure tests on bent tubes. The results demonstrated that the behavior of the bent tube was consistent with the mechanical properties of the as-received tube, provided due notice was accorded to the complex strain history of the bent tube. However, due to the strain-path changes occurring at the failure location, conventional approaches for monitoring strain history would yield (apparently) anomalous results.

Similar content being viewed by others

References

J. Gerlach, K.W. Blumel, U. Kneiphoff, and G. Eyl: “Material Aspects of Tube-Hydroforming”, SAE Technical Paper 1999-01-3204, SAE, Warrendale, PA, 1999.

T.B. Stoughton: Int. J. Mech. Sci., 2000, vol. 42, pp. 1–27.

A.K. Ghosh and J.V. Laukonis: 9th Biennial Congr. of IDDRG, ASM, Metals Park, OH, 1976.

A.F. Graf and W.F. Hosford: Metall. Trans. A, 1993, vol. 24A, pp. 2497–2501.

R. Davies, G. Grant, D. Herling, M. Smith, R. Evert, S. Nykerk, and J. Shoup, “Formability Investigation of Aluminum Extrusions under Hydroforming Conditions”, SAE Technical Paper 2000-01-2675, SAE, Warrendale, PA, 2000.

S. Takahashi, K. Terada, T. Morita, and N. Matsubara: “Application of Hydroforming Simulation on Development of Automobile Parts”, SAE Technical Paper 2002-01-0786, SAE, Warrendale, PA, 2002.

A. Higdon, E.H. Ohlsen, W.B. Stiles, J.A. Weese, and W.F. Riley: Mechanics of Materials, 3rd ed., John Wiley & Sons, New York, NY, 1976.

J.H. Holloman: Trans. AIME, 1945, vol. 162, p. 268.

H. Wang, P. Martin, E. Houghland, F. Feng, and K. Gong: Automotive Tube Hydroforming Conf., Tube and Pipe Association International, Southfield, MI, May 15–16, 2002.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stevenson, R., Ng, BC. & Polidoro, P. Failure in internally pressurized bent tubes. Metall Mater Trans A 35, 1151–1158 (2004). https://doi.org/10.1007/s11661-004-1018-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-1018-3