Abstract

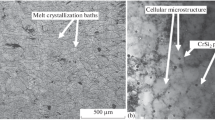

This study was aimed at the correlation of the microstructure and mechanical properties of oxide-dispersion-strengthened (ODS) coppers fabricated by internal oxidation. Atomized copper powders mixed with Cu2O oxidant powders were internally oxidized and then hot extruded to fabricate ODS coppers without defects. In order to sufficiently oxidize copper powders, oxidant powders should be added in amounts 30 pct in excess of the stoichiometrically calculated amount. In the extruded ODS coppers, very fine Al2O3 dispersoids of 10 nm in diameter were homogeneously distributed inside copper grains of 1 µm in size. The volume fraction of Al2O3 dispersoids increased as the Al content in atomized copper powders increased. With increasing volume fractions of Al2O3 dispersoids, the yield and tensile strengths increased, while the elongation and electrical conductivity decreased, and all the properties of the ODS coppers were sufficiently above the required properties of electrode materials for spot welding. To understand the mechanism responsible for the improvement of the yield strength of the ODS coppers, yield strength was interpreted using the Orowan’s strengthening model, which was fairly consistent with the experimental results.

Similar content being viewed by others

References

J.H. Mendenhall: Understanding Copper Alloys, John Wiley & Sons, New York, NY, 1980, pp. 60–64.

A. Datta and A. Soffa: Acta Metall., 1976, vol. 24, pp. 987–1001.

M. Lovell, A. Avery, and M. Vernon: Physical Properties of Materials, English Language Book Society (ELBS), London, England, 1979, p. 124.

R. Schmid: Metall. Trans. B, 1983, vol. 14B, pp. 473–81.

A.V. Nadkarni, E. Klar, and W.M. Shafer: Met. Eng. Q., 1976, vol. 8, pp. 10–15.

B.D. Cullity: Elements of X-ray Diffraction, Addison-Wesley, Reading, MA, 1956, pp. 409 and 415.

B. Bovarnick and H.W. Flood: Progress in Powder Metallurgy, MPIF, New York, NY, 1964, vol. 20, pp. 64–81.

G.P. Tomaino: Analytica Chimica Acta, 1994, vol. 286, pp. 75–80.

S.-I. Yamada and N. Komatsu: J. Jpn Inst. Met., 1972, vol. 36, pp. 987–94.

T. Takahashi, Y. Hashimoto, and K. Koyama: J. Jpn. Inst. Met., 1989, vol. 53, pp. 814–20.

D.W. Lee, G.H. Ha, and B.K. Kim: Scripta Mater., 2001, vol. 44, pp. 2137–40.

A.V. Nadkarni and E.P. Weber: Welding Res. Supp., 1977, vol. 11, pp. 331–38.

G.E. Dieter: Mechanical Metallurgy, 3rd ed., McGraw-Hill, New York, NY, 1986, pp. 188–91 and pp. 212–20.

J.W. Martin: Micromechanisms in Particle Hardened Alloys, Cambridge University Press, Cambridge, UK, 1980, pp. 62–98.

M. Abdelrahman: Jpn. J. Appl. Phys., 1997, vol. 36, pp. 6530–32.

R.M. Aikin, Jr.: J. Met., 1997, vol. 8, pp. 35–39.

J. Lee, N.J. Kim, J.Y. Jung, E.-S. Lee, and S. Ahn: Scripta Mater., 1998, vol. 39, pp. 1063–69.

J. Lee, E.-S. Lee, W.J. Park, J.Y. Jung, S. Ahn, and N.J. Kim: Met. Mater., 1999, vol. 5, pp. 141–47.

A. Rohatgi, K.S. Vecchio, and G.T. Gray: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 135–45.

R.W. Armstrong: in Yield, Flow, and Fracture of Polycrystals, T.N. Baker, ed., Applied Science Publishers, London, 1983, pp. 1–31.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, J., Kim, Y.C., Lee, S. et al. Correlation of the microstructure and mechanical properties of oxide-dispersion-strengthened coppers fabricated by internal oxidation. Metall Mater Trans A 35, 493–502 (2004). https://doi.org/10.1007/s11661-004-0360-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0360-9