Abstract

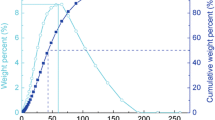

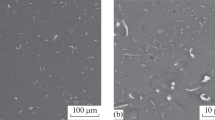

When a hypereutectic aluminum-silicon alloy containing 16 wt pct silicon was rapidly solidified into powder using the spinning water atomization process, the individual powder grains were predominantly aluminum that was supersaturated with silicon and also contained well-dispersed 0.02-µm silicon particles. Although the silicon particles grew when the powder was extruded into a bar at temperatures from 673 to 803 K at an extrusion ratio of 4.3 and an extrusion speed of 0.9 mm/s, the average diameter was maintained on a submicron level. When the extrusion temperature was decreased from 803 to 673 K, the average diameter of the silicon particles in the extruded bar decreased from 0.8 to 0.5 µm, while the Vickers hardness (HV) and the ultimate tensile strength of the extruded bar increased from 120 to 160 (HV) and from 330 to 500 MPa, respectively. Both the hardness and the tensile strength of the extruded bars were several times higher than those of conventionally cast bars of the same alloy with cooling rates from 10−1 to 102 K/s. On the other hand, the elongation decreased from 5.5 to 3.1 pct when the extrusion temperature was decreased from 803 to 673 K.

Similar content being viewed by others

References

N. Kuroishi: J. JSTP, 2001, vol. 42, pp. 397–401.

H. Yamagata: Mater. Sci. Forum, 1999, vols. 304–306, pp. 797–803.

T. Ohmi, M. Minoguchi, M. Kudoh, Y. Itoh, K. Matsuura, and K. Ishii: Trans. Jpn. Inst. Met., 1994, vol. 58, pp. 324–29.

T. Ohmi, M. Kudoh, K. Ohsasa, Y. Itoh, K. Matsuura, and K. Ishii: J. Jpn. Light Met., 1994, vol. 44, pp. 91–96.

T.S. Kim, B.T. Lee, C.R. Lee, and B.S. Chun: Mater. Sci. Eng., 2001, vols. A304–A306, pp. 617–20.

M. Yoshino, T. Aoki, F. Kasai, and K. Kobiki: Kubota Tech. Rep., 1995, vol. 29, pp. 7–15.

J.L. Murray and A.J. McAlister: in Binary Alloy Phase Diagrams, T.B. Massalski, ed., ASM, Materials Park, OH, 1986, pp. 164–65.

E. Orowan: Symp. on Internal Stresses, Institute of Metals, London, 1947, p. 451; as discussed in G.E. Dieter: Mechanical Metallurgy, 2nd ed., McGraw-Hill, New York, NY, 1976, pp. 221–27.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Matsuura, K., Ohmi, T., Kudoh, M. et al. Dispersion strengthening in a hypereutectic Al-Si alloy prepared by extrusion of rapidly solidified powder. Metall Mater Trans A 35, 333–339 (2004). https://doi.org/10.1007/s11661-004-0134-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0134-4