Abstract

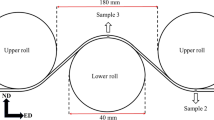

The evolution of surface topography and crystallographic texture was investigated under balanced biaxial stretching in sheets of the aluminum alloy 5052-H32. Two different lots of material, with an initial nominal thickness of 1 mm, were tested in the as-received condition. Samples with increasing levels of balanced biaxial strain were deformed using a modified Marciniak in-plane stretching test. In general, the sheet materials were microstructurally and crystallographically anisotropic. Between the two lots, the initial microstructure and mechanical properties were found to be equivalent; however, the sheet texture was appreciably different. This latter variation was observed to have an effect on the additional roughening of the surface subsequent to deformation. For a given lot of material, the surface roughness was found to be proportional to the magnitude of the strain. However, while the roughening rates for the two lots were comparable, the lot having a stronger initial {220} texture component was found to roughen to a higher degree. Corresponding changes in the sheet texture were observed to have two regimes as a function of the strain level. In the first regime, typically, for strains (ɛ) up to 0.05, the orientations were found to rotate quickly away from the initial cube {001}〈100〉 orientation observed in the as-received sheet toward positions along the α fiber. Above a strain level of 0.05, the {220} texture component continued to increase with deformation, but at a decreasing rate up to failure of the sheet. The difference in the grain rotation rates observed did not appear to have an effect on the surface roughening, as the relative change of the crystallographic orientations with increasing plastic strain was similar for both heats of material. Instead, it is believed that localized grain or grain-grouping interactions may play a more important role in the surface roughening process.

Similar content being viewed by others

References

R. Becker: Acta Mater., 1998, vol. 46 (4), pp. 1385–1401.

C. Guangnan, S. Huan, H. Shiguang, and B. Baudelet: Mater. Sci. Eng., 1990, vol. 128A, pp. 33–38.

P.F. Thomson and P.U. Nayak: Int. J. Mach. Tool Des. Res., 1980, vol. 20, pp. 78–86.

Y.Z. Dai and F.P. Chiang: Trans. ASME, 1992, vol. 114, pp. 432–38.

A. Azushima and M. Miyagawa: J. Jpn. Soc. Technol. Plasticity, 1986, vol. 27, pp. 1261–67.

D.V. Wilson, W.T. Roberts, and P.M.B. Rodrigues: Metall. Trans. A, 1981, vol. 12A, pp. 1595–1602.

K. Osakada and M. Oyane: Bull. JSME, 1971, vol. 14 (68), pp. 171–77.

M. Fukuda, K. Yamaguchi, N. Takakura, and Y. Sakano: J. Jpn. Soc. Technol. Plasticity, 1974, vol. 15, p. 994.

H. Kaga: Ann. Coll. Int. Etud. Sci. Tech. Prod. Mec., 1971, vol. 20, pp. 55–67.

N.J. Wittridge and R.D. Knutsen: Mat. Sci. Eng., 1999, vol. 269A, pp. 205–16.

W.R.D. Wilson and W. Lee: Proc. 1st Int. Conf. on Tribology in Manufacturing Processes ’97, Gifu, Japan, 1997, pp. 71–76.

A.J. Beaudoin, J.D. Bryant, and D.A. Korzekwa: Metall. Trans., 1998, vol. 29A, pp. 2323–32.

D.V. Wilson, W.T. Roberts, and P.M.B. Rodrigues: Metall. Trans. A, 1981, vol. 12A, pp. 1603–11.

R. Becker and S. Panchanadeeswaran: Acta Mater., 1995, vol. 43 (7), pp. 2701–19.

Z. Maciniak and K. Kuczynski: Int. J. Mech. Sci., 1967, vol. 9, pp. 609–20.

T.J. Foecke, S.W. Banovic, and R.J. Fields: JOM, 2001, vol. 53 (2), pp. 27–30.

C.S. Choi, H.J. Prask, and S.F. Trevino: J. Appl. Crystallogr., 1979, vol. 12, pp. 327–331.

M.D. Vaudin: Proc. 12th Int. Conf. on Textures of Materials, J.A. Szpunar, in NRC Research Press, Ottawa, 1999, pp. 186–91.

M.D. Vaudin, M.W. Rupich, M. Jowett, G.N. Riley, and J.F. Bingert: J. Mater. Res., 1998, vol. 13 (10), pp. 2910–19.

M.D. Vaudin: TexturePlus, http://www.ceramics.nist.gov/webbook/TexturePlus/texture.htm, 2000.

P.R. Dawson and A.J. Beaudoin: JOM, 1997, vol. 49 (9), pp. 34–41.

X.Y. Wen and W.B. Lee: Scripta Mater., 2000, vol. 43 (1), pp. 1–7.

X.M. Cheng, Y. Liu, and J.G. Morris: Alum. Trans., 1999, vol. 1 (1), pp. 103–08.

J.J. Park: J. Mater. Proc. Technol., 1999, vol. 87 (1–3), pp. 146–53.

B. Ren, J.G. Morris, and A.J. Beaudoin: JOM, 1996, vol. 48 (6), pp. 22–25.

L.S. Toth, J. Hisch, and P. VanHoutte: Int. J. Mech. Sci., 1996, vol. 38 (10), pp. 1117–26.

S. Panchanadeeswaran and D.P. Field: Acta Mater., 1995, vol. 43 (4), pp. 1683–92.

Y. Zhou and K.W. Neale: Acta Mater., 1994, vol. 42 (6), pp. 2175–89.

Y. Zhou and K.W. Neale: Textures Microstr., 1993, vol. 22, pp. 87–111.

J.C. Starczan, D. Ruer, and R. Baro: Proc. ICOTOM 6, Iron and Steel Institute, Tokyo, 1981, pp. 308–316.

In Aluminum: Properties and Physical Metallurgy, J.E. Hatch, ed., ASM, Metals Park, OH, 1984, pp. 64–66.

S.S. Hecker: J. Eng. Mater.-Trans. ASME, 1975, vol. 97 (1), pp. 66–73.

A.K. Ghosh and S.S. Hecker: Metall. Trans., 1974, vol. 5, pp. 2161–64.

M. Huang and J.C. Gerdeen: in Computer Applications in Shaping and Forming of Materials, M.Y. Demeri, ed., TMS, Warrendale, PA, 1992, pp. 239–49.

J.C. Williams, A.W. Thompson, and R.G. Baggerly: Scripta Metall., 1974, vol. 8, pp. 625–30.

D.V. Wilson and O. Acselrad: Proc. IDDRG 10th Biennial Congr., Portcullis Press, Redhill, UK, 1978, vol. 155.

T. Kobayashi, K. Murata, and H. Ishigaki: J. Jpn. Soc. Technol. Plasticity, 1969, vol. 10, p. 793.

S. Kohara: Proc. ICOTOM 6, Iron and Steel Institute, Tokyo, 1981, pp. 300–07.

C.Y. Tang and W.H. Tai: J. Mater. Proc. Technol., 2000, vol. 99, pp. 135–40.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Banovic, S.W., Foecke, T. Evolution of strain-induced microstructure and texture in commercial aluminum sheet under balanced biaxial stretching. Metall Mater Trans A 34, 657–671 (2003). https://doi.org/10.1007/s11661-003-0100-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0100-6