Abstract

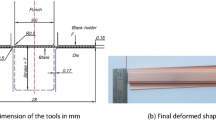

The work-hardening characteristics of metals deeply affect the analytical and numerical analyses of their forming processes and especially the end mechanical properties of the products manufactured. The effects of strain, strain rate, and temperature on work hardening have received wide attention in the literature, but the role of the strain path has been far less studied, except for sheet-metal forming. Strain-path effects seem to have never been analyzed for bulk-forming processes, such as axisymmetric drawing. In the present work, drawn bars were considered as composed of concentric layers strained along varying strain paths. The tensile von Mises effective stress, effective-strain curves of two layers and of the full cross section of the drawn material, were experimentally determined. The flow behavior of these regions was compared to that resulting from pure monotonic-tensile processing. The AISI 420 and 304 stainless steels revealed a strain path and a material effect on their work-hardening characteristics. Higher or lower hardening rates were observed in axisymmetric drawing, as compared to pure tension. These phenomena were interpreted by considering the dislocation arrangements caused by initial drawing straining and their subsequent restructuring, associated with the strain-path change represented by tension after drawing. The analytical and numerical analyses of the tensile behavior of metals following axisymmetric drawing must consider the strain-path effects on the constitutive equations laws and on the hardening behavior of the material. The redundant deformation factor in axisymmetric drawing (φ) plays a central role in the analysis of the process and on the prediction of the mechanical properties of the final products. This parameter was evaluated considering (a) the strain distribution in the bar cross section caused by drawing or (b) the mechanical properties of the drawn bars. The comparison of the results from these two approaches allowed an unexplained interpretation of a material effect on this parameter.

Similar content being viewed by others

References

R.H. Wagoner: Metall. Trans. A, 1982, vol. 13A, pp. 1491–1500.

J.V. Laukonis and A.K. Ghosh: Metall. Trans. A, 1978, vol. 9A, pp. 1849–56.

A.K. Ghosh and W.A. Backofen: Metall. Trans. A, 1973, vol. 4A, pp. 1113–23.

D.V. Wilson, M. Zandrahimi, and W.T. Roberts: Acta Metall., 1990, vol. 38, pp. 215–26.

M. Zandrahimi, S. Platias, D. Price, D. Basret, W.T. Roberts, and D.V. Wilson: Metall. Trans. A, 1989, vol. 20A, pp. 2471–82.

D.J. Lloyd and H. Sang: Metall. Trans. A, 1979, vol. 10A, pp. 1767–72.

J.V. Fernandes and M.F. Vieira: Metall. Trans. A, 1997, vol. 28A, pp. 1169–79.

E.V. Nesterova, B. Bacroix, and C. Teodosiu: Mater. Sci. Eng. A, 2001, vol. A309–310, pp. 495–99.

B. Peeters, M. Seefeldt, C. Teodosiu, S.R. Kalidindi, P. Van Houtte, P. Aernoudt and E. Aernoudt: Acta Mater., 2001, vol. 49, pp. 1607–19.

B. Peeters, B. Bacroix, C. Teodosiu, P. Van Houtte, and E. Aernoudt: Acta Mater., 2001, vol. 49, pp. 1621–32.

E.C.S. Corrêa, M.T.P. Aguilar, W.A. Monteiro, and P.R. Cetlin: J. Mater. Sci. Lett., 2000, vol. 19, pp. 779–81.

W.A. Backofen: Deformation Processing, 1st. ed., Addison-Wesley, Reading, MA., 1972.

M.P. Riendeau, M.C. Mataya, and D.K. Matlock: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 363–75.

B. Avitzur: Metal Forming: Processes and Analysis. 1st ed, McGraw-Hill, New York, NY, 1968.

R.M. Caddel and A.G. Atkins: Trans. ASME B-J. Eng. Ind., 1968, pp. 411–19.

A.P. Green and R. Hill: J. Mech. Phys. Sol., 1952, vol. 1, pp. 31–36.

L. Sadok, J. Luksza, J. Majta, and A. Skoliszewski: J. Mater. Proc. Technol., 1994, vol. 45, pp. 293–98.

L. Sadok, J. Luksza, M. Packo, and M. Buerdek: J. Mater. Proc. Technol., 1994, vol. 45, pp. 305–10.

R.B. Gifford, A.R. Bandar, W.Z. Misiolek, and J.P. Coulter: Proc. 8th Int. Conf. on Metal Forming, Kraków, Poland, 2000, pp. 567–77.

Y. Strauwen and E. Aernoudt: Acta Metall., 1987, vol. 35, pp. 1029–36.

W.J.M. Tegart: Elements of Mechanical Metallurgy, 1st ed., Macmillan Company, New York, NY, 1966.

W.F. Hosford and R.M. Caddel: Metal Forming: Mechanics and Metallurgy, 2nd ed., Prentice-Hall, London, 1993.

G.E. Dieter: Mechanical Metallurgy, 2nd ed., McGraw-Hill, New York, NY, 1987, p. 625.

N.H. Polakowski and E.J. Ripling: Strength and Structure of Engineering Materials, 1st ed., Prentice-Hall, Englewood Cliffs, NJ, 1966, pp. 481–82.

G.E. Dieter: Mechanical Metallurgy, 1st ed., McGraw-Hill, New York, NY, 1966, p. 418.

Metals Handbook, ASM, Cleveland, OH, 1948, p. 241.

T.A. Trozera: Trans. ASME-J. Eng. Mater. Technol., 1964, vol. 7, pp. 309–23.

G. Krauss: Steels: Heat Treatment and Processing Principles, 2nd. ed., ASM INTERNATIONAL, Materials Park, OH, 1999.

D.V. Wilson and P.S. Bate: Acta Metall. Mater., 1994, vol. 42, pp. 1099–1111.

A.B. Lopes, F. Barlat, J.J. Gracio, J.F.F. Duarte, and E.F. Rauch: Int. J. Plast., 2003, vol. 15, pp. 1–22.

N.H. Polakowski and A. Palchoudhuri: Proc. ASTM, 1954, vol. 54, pp. 701–16.

S.N. Buckley and K.M. Entwistle: Acta Metall., 1956, vol. 4, pp. 352–61.

S. Asgari: Metall. Mater. Trans. A, 1997, vol. 28, pp. 1781–95.

S.R. Kalidindi: Int. J. Plas., 2001, vol. 17, pp. 837–60.

W.P. Longo and R.E. Reed-Hill: Rev. Circulo Militar, 1974, vol. 71, pp. 43–49.

R.M. Caddel and A.G. Atkins: Trans. ASME B-J. Eng. Ind., 1969, pp. 664–72.

R. Hill and S.J. Tupper: J. Iron Steel Inst., 1948, vol. 158, pp. 353–59.

P.R. Cetlin: J. Eng. Mater. Technol., 1987, vol. 109, pp. 272–75.

P.R. Cetlin and J.L.N. Nicolas: J. Eng. Mater. Technol. 1987, vol. 109, pp. 276–81.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cetlin, P.R., Corrêa, E.C.S. & Aguilar, M.T.P. The effect of the strain path on the work hardening of austenitic and ferritic stainless steels in axisymmetric drawing. Metall Mater Trans A 34, 589–601 (2003). https://doi.org/10.1007/s11661-003-0094-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0094-0