Abstract

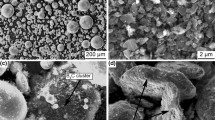

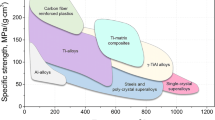

Near-γ TiAl- and Al3Ti-based intermetallic matrix composites have been produced using in-situ reaction-synthesis techniques. The intermetallic matrices have been reinforced with relatively high loadings (e.g., 20 to 50 vol pct) of dispersed TiB2 particulates. It is shown that the as-synthesized TiB2 size is strongly dependent on the specific alloy formulation; specifically, the TiB2 size tends to increase as the nominal volume percent of TiB2 in the composite increases. The observed size effect is determined to be associated with the temperature that is attained during the synthesis event, which is established primarily by the net exothermicity of the participating synthesis reaction(s). The exothermicity of the reactions can be assessed through the calculation of a formulations’s adiabatic temperature, which is found to increase with the percentage of TiB2 over the range of approximately 10 to 60 vol pct. The coupling of a composite’s characteristic adiabatic temperature with the resulting reinforcement size provides direct links among composition, processing, and mechanical performance, since the size of a reinforcing particle is influential in establishing the interparticle spacing, which, in turn, establishes the strengthening potency of the dispersed phase within the composite.

Similar content being viewed by others

References

J. Subrahmanyam and M. Vijayakumar: J Mater. Sci., 1992, vol. 27, pp. 6249–73.

Combustion and Plasma Synthesis of High-Temperature Materials, Z.A. Munir and J.B. Holt, eds., VCH, New York, NY, 1990.

D.C. Dunand: in Processing and Fabrication of Advanced Materials III, V.A. Ravi, T.S. Srivatsan, and J.J. Moore, eds., TMS, Warrendale, PA, 1994, pp. 771–93.

A.R.C. Westwood: Metall. Trans. A, 1988, vol. 19A, pp. 749–58.

H.J. Feng, K.R. Hunter, and J.J. Moore: J. Mater. Synthesis Processing, vol. 2 (2), 1994, 71–86.

O.P. Poola, C. Cordier, P. Pirouz, and A.H. Heuer: Interfaces in Metal-Ceramic Matrix Composites, TMS, Warrendale, PA, 1990, pp. 465–73.

Mechanical Metallurgy, M.A. Meyers and K.K. Chawla, eds., Prentice-Hall, Englewood Cliffs, 1984, p. 409.

S.L. Kampe, P. Sadler, D.E. Larsen, and L. Christodoulou: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 2181–97.

J.J. Moore: in Processing and Fabrication of Advanced Materials III, V.A. Ravi, T.S. Srivatsan, and J.J. Moore, eds., TMS, Warrendale, PA, 1994, pp. 817–31.

M.E. Hyman, C. McCullough, J.J. Valencia, C.G. Levi, and R. Mehrabian: Metall. Trans. A, 1989, vol. 20A, pp. 1847–59.

J.W. Martin: Micromechanisms in Particle-Hardened Alloys, Cambridge University press, New York, NY, p. 61.

I. Barin: Thermomechanical Data of Pure Substances, 2nd ed., VCH, Weinheim, 1993.

D.C. Dunand: Mater. Manufacturing Processes, 1995, vol. 10 (3), pp. 373–403.

R.N. Wright, B.H. Rabin, and W.H. McFerran: J. Mater. Res., 1992, vol. 7 (10), pp. 2733–38.

O. Kubaschewski, E. LL. Evans, and C.B. Alcock: Metallurgical Thermochemistry, 4th ed., Pergamon, Oxford, United Kingdom, 1967, vol. 1, p. 208.

W.L. Frankhouser, K.W. Brendley, and M.C. Kieszek: Gasless Combustion Synthesis of Refractory Compounds, Noyes Publications, Park Ridge, NJ, 1985, p. 52.

Y. Choi and S.-W. Rhee: J. Mater. Res., 1993, vol. 8 (12), pp. 3202–09.

A. Chrysanthou: Key Engineering Materials, 1995, vols. 104–107, pp. 381–86.

R.M. Aikin, Jr.: Los Alamos National Labs, Los Alamos, NM, private communication, 1998.

J.M. Haeberle, J.S. Marte, and S.L. Kampe: unpublished work (Senior Design Project Final Report), Virginia Tech, Blacksburg, VA, 1998.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Martin, R., Kampe, S.L., Marte, J.S. et al. Microstructure/processing relationships in reaction-synthesized titanium aluminide intermetallic matrix composites. Metall Mater Trans A 33, 2747–2753 (2002). https://doi.org/10.1007/s11661-002-0397-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0397-6