Abstract

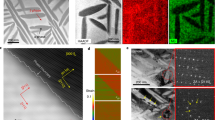

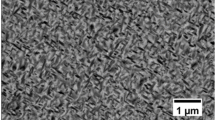

Rapid solidification by twin-anvil splat quenching captures the initial nucleation and growth of the α → γ m massive transformation in titanium aluminides. Splat quenching Ti52Al48 and Ti50Al48Cr2 from the liquid at slightly below the melting point produces an equiaxed α solidification structure. Solid-state cooling rates that approach 106 K/s arrest the α → γ m massive transformation with 1- to 5-µm-sized γ m nuclei, especially in the Ti50Al48Cr2 alloy. Classical massive-transformation heterogenous nucleation occurs at α:α grain boundaries with an orientation relationship of [111] γ //[0001] α and \(\{ 110\} _\gamma //\{ 11\bar 20\} _\alpha \). The γ m nucleus then grows into the adjacent α grain without the orientation relationship by forming an incoherent α:γ interface with {111} γ facets. Orthogonal variants of the tetragonal c-axis in the γ m product suggest that the massive transformation initially produces an fcc structure which subsequently orders into the L10 phase. Nucleation of γ m is not only observed at α:α grain boundaries and triple points, but also within the α grains. The intragranular γ m nucleation, which is believed to be heterogeneous, occurs with the same orientation relationship as for the intergranular nuclei. However, the intragrain nuclei do not form {111} γ facets and retain a curved α:γ m interface. Although analysis of the {111} γ faceted growth using weak-beam dark-field (WBDF) imaging shows no evidence for any type of misfit-compensating dislocations, lattice imaging of the {111} γ facets with high resolution transmission electron microscopy (HRTEM) reveals that the planar interface exhibits a slight curvature, produced by atomic steps of (111) planes. These experimental data have been used to estimate a ratio of ledge spacing (λ) to ledge height (h) for the {111} γ facets as λ/h=41, which is similar to calculated values for a ledge growth mechanism of massive transformations in Cu-Zn and Ag-Cd alloys.

Similar content being viewed by others

References

S.K. Bhattacharyya, J.H. Perepezko, and T.B. Massalski: Acta Metall., 1974, vol. 22, pp. 879–86.

J.H. Perepezko: Metall. Trans. A, 1984, vol. 15A, pp. 437–47.

M.R. Plichta, W.A.T. Clark, and H.I. Aaronson: Metall. Trans. A, 1984, vol. 15A, pp. 427–35.

E.B. Hawbolt and T.B. Massalski: Metall. Trans., 1970, vol. 1, pp. 2315–22.

J.D. Ayers and and D.C. Joy: Acta Metall., 1972, vol. 20 pp. 1371–79.

J.D. Ayers: Acta Metall., 1980, vol. 28, pp. 1513–22.

M.R. Plichta, J.H. Perepezko, H.I. Aaronson, and W.F. Lange III: Acta Metall., 1980, vol. 28, pp. 1031–40.

M.R. Plichta and H.I. Aaronson: Acta Metall., 1980, vol. 28 pp. 1041–57.

E.S.K. Menon, M.R. Plichta, and H.I. Aaronson: Acta Metall., 1988, vol. 36, pp. 321–32.

P. Wang, G.B. Viswanathan, and V.K. Vasudevan: Metall. Trans. A, 1992, vol. 23A, pp. 690–97.

P. Wang and V.K. Vasudevan: Scripta Metall., 1992, vol. 27, pp. 89–94.

S.A. Jones and M.J. Kaufman: Acta Metall., 1993, vol. 41, pp. 387–98.

X.D. Zhang, S. Godfrey, M. Weaver, M. Strangwood, P. Threadgill, M.J. Kaufman, and M.H. Loretto: Acta Mater., 1996, vol. 44, pp. 3723–34.

X.D. Zhang, Y.G. Li, M.J. Kaufman, and M.H. Loretto: Acta Mater., 1996, vol. 44, pp. 3735–47.

P. Wang, M. Kumar, D. Veeraraghaven, and V.K. Vasudevan: Acta Mater., 1998, vol. 46, pp. 13–30.

D. Veeraraghavan, P. Wang, and V.K. Vasudaven: Acta Mater., 1999, vol. 47 (11), pp. 3313–30.

J.E. Wittig and W.H. Hofmeister: Microsc. Microanal., 1998, vol. 4 (2) pp. 538–39.

T.M. Miller, L. Wang, W.H. Hofmeister, J.E. Wittig, and I.M. Anderson: Mater. Res. Soc. Symp. Proc., 2001 vol. 589 pp. 123–28.

D.E. Simms: Master’s Thesis, Vanderbilt University, Nashville, TN, 1996.

M.H. Loretto and R.E. Smallman: Defect Analysis in Electron Microscopy, John Wiley and Sons Inc., New York, NY, 1975, pp. 91–98.

H.I. Aaronson: Metall. Trans. A, 1993, vol. 24A, pp. 241–76

H.I. Aaronson and F.K. LeGoues: Metall. Trans. A, 1992, vol. 23A, pp. 1915–44.

Author information

Authors and Affiliations

Additional information

This article is based on a presentation made at the symposium entitled “The Mechanisms of the Massive Transformation,” a part of the Fall 2000 TMS Meeting held October 16–19, 2000, in St. Louis, Missouri, under the auspices of the ASM Phase Transformations Committee.

Rights and permissions

About this article

Cite this article

Wittig, J.E. The massive transformation in titanium aluminides: Initial stages of nucleation and growth. Metall Mater Trans A 33, 2373–2379 (2002). https://doi.org/10.1007/s11661-002-0360-6

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0360-6