Abstract

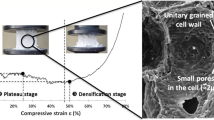

Experiments have been carried out to study the effects of macroscopic pores on the damping behavior of foamed commercially pure aluminum (FA). The damping characterization was conducted on a multifunction internal friction apparatus (MFIFA). The FA specimens were prepared by an air pressure infiltration process. The size of the macroscopic pores was on the order of a millimeter and in large proportions, typically, up to 56 vol pct. The internal friction (IF) of the FA specimen was measured at low frequencies at room temperature. The measured IF shows that FA has a damping capacity, which is enhanced in comparison with bulk commercially pure aluminum, increases with increasing porosity, increases with decreasing macropore size, increases with increasing frequency, and increases with increasing strain amplitude. The microstructural analysis was performed using transmission electron microscopy (TEM). The TEM observations show that a moderate density of dislocation substructures exists near the grain boundaries in the FA. In order to explain these phenomena, the possible operative damping mechanisms in the FA are discussed in light of IF measurements and microstructural observations, and an approximate expression for IF is derived, which is based on the equation of plane waves in elastic material with voids.

Similar content being viewed by others

References

G.J. Davies and Shu Zhen: J. Mater. Sci., 1983, vol. 18, pp. 1899–1911.

J. Zhang, R.J. Perez, and E.J. Lavernia: Acta Metall. Mater. A, 1994, vol. 42, pp. 395–98.

X. Yu and D. He: Mater. Mech. Eng. (China), 1994, vol. 18, pp. 26–30 (in Chinese).

J. Zhang, M.N. Gungor, and E.J. Lavernia: J. Mater. Sci., 1993, vol. 28, pp. 1515–21.

G.J. Davis and S. Zhen: J. Mater. Sci., 1983, vol. 18, pp. 1899–1902.

T. Mura: Micromechanics of Defects in Solids, Martinus Nijhoff Publishers, Dordrecht, The Netherlands, 1987, pp. 97–99.

J. Banhart, J. Baumeister, and M. Weber: Mater. Sci. Eng., 1996, vol. A205, pp. 221–27.

J.D. Eshelby: Proc. R. Soc. A, 1957, vol. 241, pp. 376–80.

G.P. Tandon and G.J. Weng: J. Appl. Mech., 1986, vol. 53, pp. 511–14.

C.S. Liu, Z.G. Zhu, F.S. Han, and J. Banhart: Phil. Mag. A, 1998, vol. 78, pp. 1329–37.

J.N. Wei, Z.B. Li, and F.S. Han: Phys. Status Solidi A, 2002, vol. 191, pp. 125–36.

A. Granato and K. Lücke: J. Appl. Phys., 1956, vol. 27, pp. 583–90 and 789–92.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wei, J.N., Cheng, H.F., Gong, C.L. et al. Effects of macroscopic pores on the damping behavior of foamed commercially pure aluminum. Metall Mater Trans A 33, 3565–3568 (2002). https://doi.org/10.1007/s11661-002-0344-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0344-6