Abstract

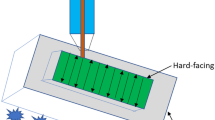

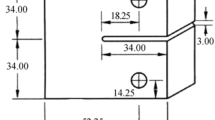

Iron-based weld hardfacing deposits are used to provide a wear-resistant surface for a structural base material. Iron-based hardfacing alloys that are resistant to corrosion in oxygenated aqueous environments contain high levels of chromium and carbon, which results in a dendritic microstructure with a high volume fraction of interdendrite carbides which provide the needed wear resistance. The ferrite content of the dendrites depends on the nickel content and base composition of the iron-based hardfacing alloy. The amount of ferrite in the dendrites is shown to have a significant influence on the hardness and galling wear resistance, as determined using ASTM G98 methods. Fracture-toughness (K IC) testing in accordance with ASTM E399 methods was used to quantify the damage tolerance of various iron-based hardfacing alloys. Fractographic and microstructure examinations were used to determine the influence of microstructure on the wear resistance and fracture toughness of the iron-based hardfacing alloys. A crack-bridging toughening model was shown to describe the influence of ferrite content on the fracture toughness. A higher ferrite content in the dendrites of an iron-based hardfacing alloy reduces the tendency for plastic stretching and necking of the dendrites, which results in improved wear resistance, high hardness, and lower fracture-toughness values. A NOREM 02 hardfacing alloy has the most-optimum ferrite content, which results in the most-desired balance of galling resistance and high K IC values.

Similar content being viewed by others

References

J.R. Davis: Welding, Brazing, and Sodering, Materials Handbook, ASM INTERNATIONAL, Materials Park, OH, 1993, vol. 6, pp. 789–829.

P. Crook and H.N. Farmer: Friction, Lubrication, and Wear Technology, Materials Handbook, ASM INTERNATIONAL, Materials Park, OH, 1992, vol. 18, pp. 758–65.

S.A. Shiels, W.L. Wilson, K.W. Rosengarth, and G.L. Wire: Proc. 3rd Int. Symp. on Contribution of Materials Investigation to the Reduction of Problems Encountered in Pressurized Water Reactors, Fontevraund, France, 1994. Available as WAPD-T-3032, DOE/OSTI, Oak Ridge, TN, 1994, pp. 1–8.

B.V. Cockeram, R.F. Buck, and W.L. Wilson: Surf. Coatings Technol., 1997, vols. 94–95, pp. 495–500.

B.V. Cockeram: Surf. Coatings Technol., 1998, vols. 108–109, pp. 377–84.

B.V. Cockeram: Corrosion, 2000, vol. 56(8), pp. 849–59.

B.V. Cockeram: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 33–56.

E.K. Ohriner, T. Wada, E.P. Whelan, and H. Ocken: Metall. Trans. A, 1991, vol. 22A, pp. 983–91.

E.K. Ohriner and E.P. Whelan: Development of Cobalt-Free Hard-Facing Alloys for Nuclear Applications: 1985 Progress, EPRI, Palo Alto, CA, 1985, NP-4237.

Standard Test Method for Measurement of Fracture Toughness, ASTM E1820-99, ASTM, Philadelphia, PA, 1999.

Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials, ASTM E399-90, ASTM, Philadelphia, PA, 1997.

Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics, ASTM C1239-95, ASTM, Philadelphia, PA, 1995.

Standard Test Method for Measurement of Fatigue Crack Growth Rates, ASTM E647-00, ASTM, Philadelphia, PA, 2000.

Standard Test Method for Galling Resistance of Materials, ASTM G98, ASTM, Philadelphia, PA, 1997.

A.G. Evans: J. Am. Ceramic Soc., 1990, vol. 73, pp. 187–206.

M.F. Ashby, F.J. Blunt, and M. Bannister: Acta Metall., 1989, vol. 37, pp. 1847–57.

S. Suresh: Metall. Trans. A, 1985, vol. 16A, pp. 249–60.

N.S. Stoloff: Materials Handbook, vol. I, Properties and Selection: Irons, Steels, and High Performance Alloys, ASM INTERNATIONAL, Materials Park, OH, 1990, pp. 950–1007.

R.O. Ritchie: Int. Met. Rev., 1979, vol. 20, pp. 205–30.

C.J. Gilbert, J.J. Cao, W.J. Moberlychan, L.C. Dejonghe, and R.O. Ritchie: Acta Metall. Mater., 1996, vol. 44, pp. 3199–214.

K.T. Venkateswara Rao, C.J. Gilbert, and R.O. Ritchie: in Processing and Design Issues in High Temperature Materials, N.S. Stoloff and R.H. Jones, eds. TMS, Warrendale, PA, 1997, pp. 209–20.

K.S. Ravichandran: Scripta Metall. Mater., 1992, vol. 26, pp. 1389–93.

D.E. Alman and N.S. Stoloff: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 289–303.

J. Kajuch, J. Short, and J.J. Lewandowski: Acta Metall. Mater., 1995, vol. 43, pp. 1955–67.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cockeram, B.V. Some observations of the influence of δ-ferrite content on the hardness, galling resistance, and fracture toughness of selected commercially available iron-based hardfacing alloys. Metall Mater Trans A 33, 3403–3419 (2002). https://doi.org/10.1007/s11661-002-0328-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0328-6