Abstract

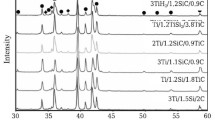

Ti/Si/TiC powders with molar ratios of 1:1:2 (M1) and 2:2:3 (M2) were prepared for the synthesis of a ternary carbide Ti3SiC2 by using the mixture method for 24 hours in an Ar atmosphere. The synthesis process was conducted at 1200 °C to 1400 °C under a pressure of 50 MPa, using the pulse-discharge sintering (PDS) technique. After sintering, the phase constituents and microstructures of the samples were analyzed by X-ray diffraction (XRD) technique and observed by optical microscopy and scanning electron microscopy. The results showed that the phases in all the samples consisted of Ti3SiC2 and small amounts of TiC, and the optimum sintering temperature was found to be in the relatively low range of 1250 °C to 1300 °C. By the standard additive method, the relative content of Ti3SiC2 was calculated. For the M1 samples, the lowest TiC content can be only decreased to about 3 to 4 wt pct, whereas the content of Ti3SiC2 in the M2 samples is always lower than that in the M1 samples. When the M2 powder was sintered at 1300 °C for 8 to 240 minutes, the TiC peaks were found to show a very low intensity, and the corresponding content of Ti3SiC2 was calculated to be higher than 99 wt pct. The grain size of Ti3SiC2 increased from 5 to 10 µm to 80 to 100 µm in the entire applied sintering temperature range. The relative density of the M2 samples was measured to be higher than 99 pct at sintering temperatures above 1275 °C. It indicates that the PDS technique can rapidly synthesize high-content Ti3SiC2 from the Ti/Si/TiC powders in a relatively low temperature range.

Similar content being viewed by others

References

M.W. Barsoum: Progr. Solid State Chem., 2000, vol. 28, pp. 201–81.

M.W. Barsoum and T. El-Raghy: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 363–69.

M.W. Barsoum, L. Farber, and T. El-Raghy: Metall. Mater. Trans. A, 1998, vol. 29, pp. 1727–38.

M.W. Barsoum, D. Brodkin, and T. El-Raghy: Scripta Mater., 1997, vol. 36, pp. 535–41.

W. Jeitschko and H. Nowotny: Monath. Chem., 1967, vol. 98, pp. 329–37.

T. Goto and T. Hirai: Mater. Res. Bull., 1987, vol. 22, pp. 1195–1201.

S. Arunajatesan and A.H. Carim: J. Am. Ceram. Soc., 1995, vol. 78, pp. 667–72.

R. Pampuch, J. Lis, L. Stobierski, and M. Tymkiewicz: J. Eur. Ceram. Soc., 1989, vol. 5, pp. 283–87.

J. Lis, Y. Miyamoto, R. Pampuch, and K. Tanihata: Mater. Lett., 1995, vol. 22, pp. 163–68.

N.F. Gao, Y. Miyamoto, and K. Tanihata: J. Mater. Sci., 1999, vol. 34, pp. 4385–92.

J.F. Li, F. Sato, and R. Watanabe: J. Mater. Sci. Lett., 1999, vol. 18, pp. 1595–97.

F. Sato, J.F. Li, and R. Watanabe: Mater. Trans. JIM, 2000, vol. 41, pp. 605–09.

M.W. Barsoum and T. El-Raghy: J. Am. Ceram. Soc., 1996, vol. 79, pp. 1953–56.

T. El-Raghy and M.W. Barsoum: J. Am. Ceram. Soc., 1999, vol. 82, pp. 2849–54.

C. Racault, F. Langlais, and R. Naslain: J. Mater. Sci., 1994, vol. 29, pp. 3384–92.

R. Radhakrishnan, C.H. Henager, Jr., J.L. Brimhall, and S.B. Bhaduri: Scripta Mater., 1996, vol. 34, pp. 1809–14.

R. Radhakrishnan, J.J. Williams, and M.J. Akinc: J. Alloys Compounds, 1999, vol. 285, pp. 85–88.

Y.C. Zhou, Z.M. Sun, S.Q. Chen, and Y. Zhang: Mater. Res. Innov., 1998, vol. 2, pp. 142–46.

Z.M. Sun and Y.C. Zhou: Scripta Mater., 1999, vol. 41, pp. 61–66.

J.T. Li and Y. Miyamoto: J. Mater. Synth. Proc., 1999, vol. 7, pp. 91–96.

Z.F. Zhang, Z.M. Sun, H. Hashimoto, and T. Abe: Scripta Mater., 2001, vol. 45, pp. 1461–67.

Z.F. Zhang, Z.M. Sun, H. Hashimoto, and T. Abe: Mater. Res. Innov., 2002, vol. 5, pp. 185–89.

K. Matsugi, T. Hatayama, and O. Yanagisama: Intermetallics, 1999, vol. 7, pp. 1049–57.

R.S. Mishra, J.E. Schneider, J.F. Shackeford, and A.K. Mukheijee: Nanostruct. Mater., 1995, vol. 5, pp. 525–44.

S.W. Wang, L.D. Chen, Y.S. Kang, M. Niino, and T. Hirai: Mater. Res. Bull., 2000, vol. 35, pp. 619–28.

J.L. Rattliff and G.W. Powell: AFML Technical Report 70-42, National Technical Information Service, Alexander, VA (1970).

M. Naka, J.C. Feng, and J.C. Schuster: Metall. Mater. Trans. A, 1997, vol. 28, pp. 1385–90.

Z.M. Sun, Z.F. Zhang, H. Hashimoto, and T. Abe: Mater. Trans., 2002, vol. 43, pp. 436–38.

T. El-Raghy, M.W. Barsoum, A. Zavaliangos, and S.R. Kalidindi: J. Am. Ceram. Soc., 1999, vol. 82, pp. 2855–60.

Z.F. Zhang, Z.M. Sun, H. Hashimoto, and T. Abe: Mater. Lett., 2002, in press.

Z.F. Zhang, Z.M. Sun, H. Hashimoto, and T. Abe: J. Eur. Ceram. Soc., 2002, in press.

T. Iseki, T. Yano, and Y.-S. Chung: J. Am. Ceram. Soc., 1990, vol. 97, pp. 47–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhang, Z.F., Sun, Z.M. & Hashimoto, H. Rapid synthesis of ternary carbide Ti3SiC2 through pulse-discharge sintering technique from Ti/Si/TiC powders. Metall Mater Trans A 33, 3321–3328 (2002). https://doi.org/10.1007/s11661-002-0320-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0320-1