Abstract

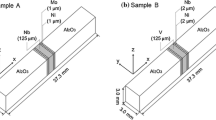

An investigation of the wide-gap, transient liquid-phase (TLP) bonding of Ti-48 at. pct Al-2 at. pct Cr-2 at. pct Nb (“48-2-2”) substrates using 48-2-2 + Cu composite interlayers produced by an automated slurry deposition process is presented in this article. The as-deposited interlayer is characterized in the article, as are the resulting bonds. The microstructures of the bonds, identified using light microscopy (LM), scanning electron microscopy (SEM), and transmission electron microscopy (TEM), are correlated with their room-temperature mechanical properties, determined using four-point bend testing. Comparisons are drawn between bonds produced by the automated slurry route and bonds with manually deposited powder interlayers, as well as interlayers produced with a presintering step.

This article considers the extent to which this automated deposition process is able to produce even and consistent interlayers, given the large difference in density between the copper and 48-2-2 constituents of the interlayer. The results presented in this article suggest that, given the selection of suitable process conditions, high-quality bonds can be produced.

Similar content being viewed by others

References

D.S. Duvall, W.A. Owczarski, and D.F. Paulonis: Weld. J., 1974, vol. 53, pp. 203–14.

R. Johnson: Weld J. (Res. Suppl.), 1981, vol. 60, pp. 185s-93s.

E. Lugscheider, T. Schittny, and E. Halmoy: Weld J. (Res. Suppl.), 1989, vol. 68, pp. 9s-13s.

W.F. Gale, Y. Xu, X. Wen, and Z.A.M. Abdo: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2723–26.

W.F. Gale, X. Wen, T. Zhou, and Y. Shen: Mater. Sci. Technol., 2001, vol. 17, pp. 1423–33.

W.F. Gale, Y. Shen, J.W. Fergus, and X. Wen: J. Mater. Res., 1999, vol. 14, pp. 3889–94.

E. Lugscheider, R. Sicking, St. Humm and H. Hallen: in Advanced Brazing and Soldering Technologies—IBSC 2000, P.T. Vianco and M. Singh, eds., American Welding Society, Miami, FL, 2000, pp. 170–78.

Smithells Metals Reference Book, E.A. Brandes and G.B. Brook, ed., Butterworth Heinemann, Oxford, United Kingdom, 1992.

Heat-Resistant Materials, J.R. Davis, 7th ed., ASM INTERNATIONAL, Materials Park, OH, 1997.

B. Dang, J.W. Fergus, and W.F. Gale: Oxid. Met., in press.

Ternary Alloys, A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams, G. Petzow and G. Effenberg, eds., VCH Publishing, New York, NY, 1991.

Y.-W. Kim: Acta Metall. Mater., 1992, vol. 40, pp. 1121–34.

Y.-W. Kim and D.M. Dimiduk: JOM, 1991, vol. 43 (8), pp. 40–41.

Y.-W. Kim: JOM, 1989, vol. 41 (7), pp. 24–30.

K. Muraleedharan, L.L. Rishel, M. De Graef, A.W. Cramb, T.M. Pollock, and G.T. Gray III: in Structural Intermetallics 1997, M.V. Nathal, R. Darolia, C.T. Liu, P.L. Martin, R. Wagner, and M. Yamaguchi, eds., TMS, Warrendale, PA, 1997, pp. 215–24.

F. Appel and R. Wagner: Mater. Sci. Eng., 1998, vol. R22, pp. 187–268.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gale, W.F., Butts, D.A., Zhou, T. et al. Microstructure and mechanical properties of titanium aluminide wide-gap, transient liquid-phase bonds prepared using a slurry-deposited composite interlayer. Metall Mater Trans A 33, 3205–3214 (2002). https://doi.org/10.1007/s11661-002-0306-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0306-z