Abstract

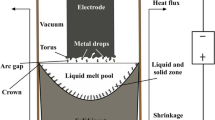

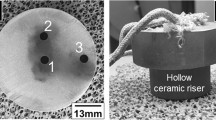

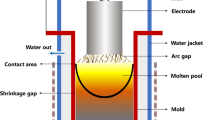

Tree-ring grain formations, a common microstructural feature found in vacuum arc remelted (VAR) ingots of nickel-based superalloys, were characterized experimentally in Part I. The experimental observations led to the conclusion that tree rings are chains of fine-equiaxed grains interrupting a predominately columnar-dendritic structure. Several possible mechanisms for their formation were considered, and their implications correlated with experimental observations. The most likely mechanism was determined to be that process perturbations cause changes in the thermal (or solutal) fields ahead of the columnar-dendrite tips, temporarily altering the conditions to increase grain nucleation and, hence, forming fine-equiaxed grains. In this article, Part II, a multiscale mathematical model of the VAR process is presented that simulates the macroscopic heat and momentum transport and combines it with a mesoscopic model of the nucleation and growth of grains. Using this multiscale model, the transient development of the VAR grain structure was simulated with varying levels and durations of fluctuations in the principal process parameters: power supply, arc focus, melt rate, and the ingot-crucible heat-transfer coefficient. The simulations were shown to agree with optical and electron back-scattered diffraction (EBSD) measurements of grain morphology and crystallographic orientation. The model results predict that tree-ring structures (consistent with those observed experimentally) can be formed by process perturbations that alter the thermal field conditions at the solidification front. A sensitivity study of the effect of the different process fluctuations on the microstructure formation was performed, providing process maps predicting the range of conditions where tree rings will not form.

Similar content being viewed by others

References

A.S. Ballantyne and A. Mitchell: Ironmaking and Steelmaking, 1977, vol. 4, pp. 222–39.

L.A. Bertram and F.J. Zanner: Proceedings of Modeling of Casting and Welding, H.D. Brody and D. Apelian, eds., TMS-AIME, 1980, pp. 333–49.

L.A. Bertram and F.J. Zanner: Proceedings of Metallurgical Applications of Magnetohydrodynamics, H.K. Moffatt and M.R.E. Proctor, eds., The Metals Society, Cambridge, United Kingdom, 1982, pp. 283–300.

A. Jardy and D. Ablitzer: Proc. Model. of Casting, Welding and Adv. Solid. Processes V, M. Rappaz, M.R. Ozgu and K.W. Mahin, eds., TMS, Davos, Switzerland, 1990, pp. 699–706.

D.K. Gartling and P.A. Sackinger: Int. J. Num. Meth. Fluids, 1997, vol. 24, pp. 1271–89.

A. Jardy, L. Falk, and D. Ablitzer: Ironmaking and Steelmaking, 1992, vol. 19, pp. 226–32.

D.M. Stefanescu: Iron Steel Inst. Jpn. Int., 1995, vol. 35, pp. 637–50.

W.J. Boettinger, S.R. Coriell, A.L. Greer, A. Karma, W. Kurz, M. Rappaz, and R. Trivedi: Acta Mater., 2000, vol. 48, pp. 43–70.

S.G.R. Brown and N.B. Bruce: J. Mater. Sci., 1995, vol. 30, pp. 1144–50.

M. Rappaz and C.-A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

X. Xu, W. Zhang, R.C. Atwood, P.D. Lee, and M. McLean: Proceedings of 4th. Pacific Rim International Conference on Modeling of Casting and Solidification Processes IV, C.P. Hong, J.K. Choi, and D.H. Kim, eds., Hanrimwon, Seoul, 1999, pp. 109–16.

X. Xu, R.C. Atwood, S. Sridhar, P.D. Lee, M. McLean, B. Drummings, R.M. Ward, and M.H. Jacobs: Proc. Int. Symp. on Liquid Metal Processing and Casting, A. Mitchell, L. Ridgeway, and M. Baldwin, eds., AVS, Santa Fe, NM, 1999, pp. 76–89.

M.C. Schneider and C. Beckermann: Iron Steel Inst. Jpn. Int., 1995, vol. 35, pp. 665–72.

L.A. Jackman, G.E. Maurer, and S. Widge: Superalloys 718, 625, 706 and Various Derivatives, E.A. Loria, ed., TMS, Pittsburgh, PA, 1994, pp. 153–66.

W. Zhang P.D. Lee, and M. McLean: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 443–54.

J.P. Gu and C. Beckermann: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1357–66.

P. Auburtin, T. Wang, S.L. Cockcroft, and A. Mitchell: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 801–11.

P.D. Lee, R.M. Lothian, L.J. Hobbs, and M. McLean: Superalloys 1996, R.D. Kissinger, D.J. Deye, D.L. Anton, A.D. Cetel, M.V. Nathal, T.M. Pollock, and D.A. Woodford, eds., TMS, Champion, PA, 1996, pp. 435–42.

W. Kurz, B. Giovanola, and R. Trivedi: Acta Metall., 1986, vol. 34, pp. 823–30.

S. Wolfram: Rev. Modern Phys., 1983, vol. 55, pp. 601–44.

H.W. Hesselbarth and I.R. Gobel: Acta Metall. Mater., 1991, vol. 39, pp. 2135–43.

C.-A. Gandin, C. Charbon, and M. Rappaz: Proceedings of Modeling of Casting, Welding and Advanced Solidification Processes VI, T.S. Piwonka, V. Voller, and L. Katgerman, eds., TMS, Palm Coast, FA, 1993, pp. 21–28.

S.G.R. Brown, T. Williams, and J.A. Spittle: Acta Metall. Mater., 1994, vol. 42, pp. 2893–98.

J. Zou: Ph.D. Thesis, Simulation De La Solidification Eutectique Equiaxe, Ecole Polytechnique Federale de Lausanne, 1988.

P. Thevoz, J.L. Desbiolles, and M. Rappaz: Metall. Trans. A, 1989, vol. 20A, pp. 311–22.

C.-A. Gandin, M. Rappaz, and R. Tintillier: Metall. Trans. A, 1993, vol. 24A, pp. 467–79.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corp., New York, NY, 1980.

F.J. Zanner, R.L. Williamson, R.P. Harrison, H.D. Flanders, R.D. Thompson, and W.C. Szeto: in Superalloy 718—Metallurgy and Applications, E.A. Loria, ed., TMS, Warrendale, PA, 1989, pp. 17–32.

M. Rappaz, C.-A. Gandin, J.L. Desbiolles, and P.H. Thevoz: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 695–705.

L.A. Bertram, J.A. Brooks, and D.G. Evan: Proc. Int. Symp. on Liquid Metal Processing & Casting, A. Mitchell, L. Ridgway, and M. Baldwin, eds., AVS, Santa Fe, NM, 1999, pp. 156–67.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xu, X., Zhang, W. & Lee, P.D. Tree-ring formation during vacuum arc remelting of INCONEL 718: Part II. Mathematical modeling. Metall Mater Trans A 33, 1805–1815 (2002). https://doi.org/10.1007/s11661-002-0189-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0189-z