Abstract

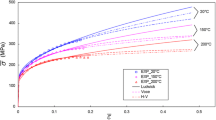

Forming limit diagrams (FLDs) are calculated based on an extension of previous analyses by Jones and Gillis,[1] Choi et. al. [2] and Pishbin and Gillis.[3] They considered the plastic behavior of sheet metals in three deformation phases using a generalized flow law and using the commonly used power hardening law to describe the stress-strain behavior. In the present study, however, the yield criterion proposed by Hosford is used in conjunction with both power-law and Voce material constitutive equations to develop a model. This model is capable of predicting the forming limit strains achievable during sheet metal forming operations for sheets having planar isotropy. The predictions from Voce and power-law equations have been compared with the experimental forming limits determined by hemispherical punch stretching of gridded blanks of AA3105 and AA8011 aluminum alloys. The results indicate good prediction of limit strains for the two alloys when the Voce equation is applied.

Similar content being viewed by others

References

S.E. Jones and P.P. Gillis: Metall. Trans. A, 1984, vol. 15A, pp. 129–32.

W. Choi, P.P. Gillis, and S.E. Jones: Metall. Trans. A, 1989, vol. 20A, pp. 1975–87.

H. Pishbin and P.P. Gillis: Metall. Trans. A, 1992, vol. 20A, pp 2817–31.

S.P. Keeler: Sheet Met. Ind., 1965, vol. 42, pp. 683–91.

G.M. Goodwin: Metall. Ital., 1968, vol. 60, pp. 767–74.

R. Mahmudi: J. Mater. Proc. Technol., 1993, vol. 37, pp. 203–16.

J. Gronostajski and Z. Zimniak: J. Mater. Proc. Technol., 1995, vol. 55, pp. 213–17.

Z. Marciniak and K. Kucznski: Int. J. Mech. Sci., 1967, vol. 9, pp. 609–20.

J.W. Hutchinson and K.W. Neale: in Mechanics of Sheet Metal Forming, D.P. Koistiner and N.M. Wang, eds., Plenum Press, New York, NY, 1978, pp. 111–53.

F. Barlat, A. Barata, Da Rocha, and J.M. Jalinier: J. Mater. Sci., 1984, vol. 19, pp. 4133–37.

S.E. Jones and P.P. Gillis: Metall. Trans. A, 1984, vol. 15A, pp. 133–38.

W. Choi, P.P. Gillis, and S.E. Jones: in Forming Limit Diagrams: Concepts, Methods, and Application, R.H. Wagoner, K.S. Chan, and S.P. Keeler, eds., TMS, Warrendale, PA, 1989, pp. 215–37.

H. Pishbin: Ph.D. Thesis, University of Kentucky, Lexington, KY, 1991, pp. 77–84.

W.F. Hosford: J. Appl. Mech., 1972, vol. 39, pp. 607–09.

R. Hill: Math. Proc. Camb. Phil. Soc., 1979, vol. 85, pp. 179–91.

J. Lian, D. Zhou, and B. Baudelet: Int. J. Mech. Sci., 1989, vol. 31, pp. 237–47.

P.P. Gillis and S.E. Jones: Int. J. Mech. Sci., vol. 21, pp. 109–17.

E. Bird and J.L. Duncan: Metall. Trans. A, 1981, vol. 12A, pp. 235–41.

D.J. Lloyd and D. Kenny: Metall. Trans. A, 1982, vol. 13A, pp. 1445–52.

P.W. Bridgman: Studies in Large Plastic Flow and Fracture, McGraw-Hill, New York, NY, 1952, p. 26.

R. Hill: J. Mech. Phys. Solids, 1952, vol. 1, pp. 19–30.

R. Mahmudi: Int. J. Mech. Sci, 1995, vol. 37, pp. 995–1010.

M. Jain, D.J. Lloyd, and S.R. Macewen: Int. J. Mech. Sci., 1996, vol. 38, pp. 219–32.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Aghaie-Khafri, M., Mahmudi, R. & Pishbin, H. Role of yield criteria and hardening laws in the prediction of forming limit diagrams. Metall Mater Trans A 33, 1363–1371 (2002). https://doi.org/10.1007/s11661-002-0061-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0061-1