Abstract

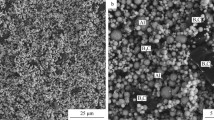

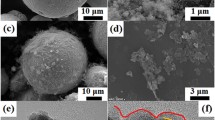

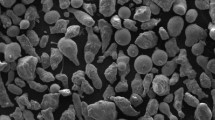

Spontaneous infiltration and strengthening behaviors were analyzed in terms of microstructures and tensile properties of AA6061/BN composite fabricated by pressureless infiltration technique in the presence of both Mg and nitrogen. The microstructure and properties were compared with control AA6061 without BN fabricated by the same method. The Mg3N2 formed by the reaction of Mg vapor and nitrogen gas, which coated the particles in the powder bed, is believed to induce spontaneous infiltration through greatly enhancing wetting by means of the reaction Mg3N2 + 2Al → 2AlN + 3Mg. This was identified by the finding of AlN particle layers on the surfaces of prior Al particles in the powder bed, which made contact with the infiltrating melt. In addition, unreacted Mg3N2 was observed outside the composite, where the Al melt did not come into direct contact. Fine AlN particles formed in situ resulted in significant strengthening, even in the control alloys with no addition of BN. In the composite reinforced with BN, additional AlN was formed by the interfacial reaction of the BN and Al melt as well as by the in situ reaction. Consequently, both the BN particles and the additional AlN particles formed by the interfacial reaction led to a further strengthening in the composite, as compared to the control alloy, which was strengthened only by the AlN particles formed in situ. In addition, the flake shape of BN may have lent considerable strength, due to the high aspect ratio it demonstrates, as compared with that of a spherically shaped particle.

Similar content being viewed by others

References

A. Mortensen and I. Jin: Int. Mater. Rev., 1992, vol. 37, pp. 101–28.

A. Ibrahim, F.A. Mohamed, and E.S. Lavernia: J. Mater. Sci., 1991, vol. 26, pp. 1137–56.

M.J. Koczak and M.K. Premkumar: J. Metall., 1993, vol. 45, pp. 44–48.

R. Asthana: J. Mater. Sci., 1998, vol. 33, pp. 1679–98.

M.K. Aghajanian, J.T. Burke, D.R. White, and A.S. Nagelberg: SAMPE Q., 1989, vol. 20 (4), pp. 43–6.

M.K. Aghajanian, M.A. Rocazella, J.T. Burke, and S.D. Keck: J. Mater. Sci., 1991, vol. 6, pp. 447–54.

A.W. Urquhart: Adv. Mater. Process, 1991, July, pp. 25–29.

A.W. Urquhart: Mater. Sci. Eng., 1991, vol. A144, pp. 75–82.

R.E. Everett and R.J. Arsenault: Metal Matrix Composites: Processing and Interfaces, Academic Press, New York, NY, 1991, pp. 121–50.

M.K. Aghajanian, A.S. Nagelberg, and C.R. Kennedy: U.S. Patent 5020584, 1991.

X.M. Xue, J.T. Wang, and M.X. Quan: J. Mater. Eng., 1991, vol. A132. pp. 277–80.

L. Shen, B.J. Tan, W.S. Willis, F.S. Galasso, and S.L. Suib: J. Am. Ceram. Soc., 1994, vol. 77. pp. 1011–16.

H. Fujii, H. Nakae, and K. Okada: Acta. Metall. NMater., 1993, vol. 41. pp. 2963–71.

X.M. Xue, J.T. Wang, and M.X. Quan: J. Mater. Sci., 1991, vol. 26. pp. 6391–95.

X.M. Xue, J.T. Wang, and F.M. Zhao: J. Mater. Sci. Lett., 1992, vol. 11. pp. 199–201.

M. Kobashi and T. Choh: J. Mater. Sci., 1997, vol. 32, pp. 6283–89.

M.G. Nicholas, D.A. Mortimer, L.M. Jones, and R.M. Crispin: J. Mater. Sci., 1990, vol. 25. pp. 2679–89

F.P. Chiaramonte and B.N. Rosenthal: J. Am. Ceram. Soc., 1991, vol. 74. pp. 658–61.

K.B. Lee, Y.S. Kim and H. Kwon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 3087–95.

K.B. Lee and H. Kwon: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2999–3007.

K.B. Lee, H.S. Sim, S.W. Heo, S.Y. Cho, and H. Kwon: Kor. Inst. Metall. Mater., 2000, vol. 6, pp. 25–32.

CRC Materials Science and Engineering Handbook, J.F. Shackelford, W. Alexander, and J.S. Park, eds., CRC, Boca Raton, FL, 1994, p. 43.

J.C. Viala, G. Gonzales, and J. Bouix: J. Mater. Sci. Lett., 1992, vol. 11. pp. 711–4.

Y. Naidich: Progr. Surf. Membrane Sci., 1981, vol. 14, p. 353.

Q. Hou, R. Mutharasan, and M. Koczak: in In Situ Reactions for Synthesis of Composites, Ceramics, and Intermetallics, E.V. Barrera, F.D.S. Marquis. W.E. Frazier, S.G. Fishman, N.N. Thadhani, and Z.A. Munir, eds., TMS-AIME, Warrendale, PA, 1995, pp. 45–55.

M. Kobashi, N. Okayama, and T. Choh: Mater. Trans. JIM, 1997, vol. 38, pp. 60–65.

I.S. Gladkaya, G.N. Kremkova, and N.A. Bendeliani: J. Mater. Sci. Lett., 1993, vol. 12, pp. 1547–48.

T. Murata, K. Itatani, F.S. Howell, A. Kishioka, and M. Kinoshita: J. Am. Ceram. Soc., 1993, vol. 76, pp. 2909–11.

F.J. Humphreys, W.S. Miller, and M.R. Djazeb: Mater. Sci. Technol., 1990, vol. 6, pp. 1157–66

M. Ferry, P. Monroe, A. Crosky, and T. Chandra: Mater. Sci. Technol., 1992, vol. 8, pp. 43–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, K.B., Ahn, J.P. & Kwon, H. Characteristics of AA6061/BN composite fabricated by pressureless infiltration technique. Metall Mater Trans A 32, 1007–1018 (2001). https://doi.org/10.1007/s11661-001-0358-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0358-5