Abstract

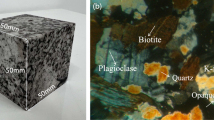

In Part I of this article, the influence of various testing parameters and environments on the fatigue-crack growth rates in samples of beta-annealed Ti-6Al-4V-0.1Ru (extra-low interstitials) ELI was reported.[1] A design-of-experiments (DOE) approach was used to survey different combinations of variables, all expected to be important for dynamically loaded offshore oil and gas production risers, and to identify significant effects on the fatigue-crack propagation rate at a stress-intensity range of ΔK=17 MPa\(\sqrt m \). The da/dN vs ΔK curves also were examined for the DOE and supplementary tests, and the results of the two approaches were compared. In this part of the study, the microstructural basis for the robust fatigue-crack growth resistance of beta-annealed Ti-6Al-4V-0.1Ru (ELI) samples was investigated with optical metallography and scanning electron microscopy (SEM). A gradual transition from structure-sensitive (microfacet formation) to structure-insensitive (striation formation) crack propagation centered at ΔK trans ≅24 MPa\(\sqrt m \), regardless of the combination of testing/environmental conditions examined; the absence of a sharp transition in the slope of the da/dN vs ΔK curves was, therefore, entirely consistent with the fracture-surface morphology. The size of the reversed cyclic plastic zone at the transition ΔK value correlated with the size of the lamella packets, but the number of cycles required to generate a striation ranged between one and ten, suggesting that the crack actively grew over only a portion of its front at any one instant. It is interesting to note that ΔK trans was the same as the stress range where the da/dN curves at 0.2, 2, and 20 Hz (in seawater) converged to a single curve (refer to Part I of this article): at lower stress ranges, crack growth rates at 20 Hz were significantly higher than those at 0.2 and 2 Hz. The quantitative data showed that fatigue cracks propagated parallel to lamellae interfaces when the long axes of the lamellae made a relatively small angle (<30 deg) to the nominal crack-propagation direction. The crack cut directly across lamellae (i.e., perpendicular to their surfaces) when the long axes of the lamellae were nearly perpendicular to the nominal crack-propagation direction. If the lamellae long axes lay 45 deg to the crack-propagation direction, the crack deflected to run parallel or perpendicular to the lamellae. This behavior occurred regardless of the environment and loading conditions investigated. There was considerable variation in the amount that the cracks deviated from their nominal plane (i.e., the plane normal to the load axis and through the notch tip), with much greater deflections in the cold-rolled than in the parent material, but the angle of the macroscopic crack plane did not exceed 11 deg. Crack branching was observed both at the center and outer surfaces of the samples, regardless of ΔK or other parameters. The relationship between micro- and macrobranches was examined, and branching was more prominent below ΔK trans, which separated the structure-sensitive and continuum-mode crack-propagation regimes. The relative amounts of micro- and microbranches are reported, and this branching may explain the large scatter in the measurements of the fatigue-crack growth rate often encountered in Ti-6Al-4V and its variants and points to the need for thorough characterization of crack paths, both midplane and surface, as part of the interpretation of da/dN vs ΔK data.

Similar content being viewed by others

References

M.A. Langøy and S.R. Stock: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2297–2314.

J.C. Chesnutt, J.C. Williams, and A.W. Thompson: in Fatigue 84, C.J. Beevers, ed., Engineering Advisory Service, Warley, United Kingdom, 1984, pp. 341–50.

P.E. Irving and C.J. Beevers: Metall. Trans., 1974, vol. 5, pp. 391–98.

P.E. Irving and C.J. Beevers: Mater. Sci. Eng., 1974, vol. 14, pp. 229–38.

A. Yuen, S.W. Hopkins, G.R. Leverant, and C.A. Rau: Metall. Trans., 1974, vol. 5, pp. 1833–42.

G. Thomson: Atta Acad. Siena, 1804, vol. 9, pp. 37–57.

K.A. Neumann: documenting work of A. von Widmanstätten: Ann. Phys., 1812, vol. 42, pp. 197–209.

T.L. Anderson: Fracture Mechanics, 2nd ed., CRC Press, Boca Raton, FL, 1995, pp. 513–58.

R.J.H. Wanhill, R. Galatolo, and C.E.W. Looije: Int. J. Fatigue, 1989, vol. 11 (6), pp. 407–16.

G.R. Yoder, L.A. Cooley, and T.W. Crooker: Metall. Trans. A, 1977, vol. 8A, pp. 1737–43.

K.S. Ravichandran: Acta Metall. Mater., 1991, vol. 39, pp. 401–10.

R.O. Ritchie and S. Suresh: Metall. Trans. A, 1982, vol. 13A, pp. 937–40.

J. Lindigkeit, G. Terlinde, A. Gysler, and G. Lütjering: Acta Metall., 1979, vol. 27, pp. 1717–26.

R.J. Bucci: Ph.D. Thesis, Lehigh University, Bethlehem, PA, 1970; cited by S. Suresh: Fatigue of Materials, Cambridge University Press, Cambridge, United Kingdom, 1991, p. 379.

J.E. Allison and J.C. Williams: in Strength of Metals and Alloys (ICSMA 6), R.C. Gifkins, ed., Pergamon Press, New York, 1983, vol. 3, pp. 1219–24.

M. Peters, A. Gysler, and G. Lütjering: Metall. Trans. A, 1984, vol. 15A, pp. 1597–1605.

D.B. Dawson and R.M. Pelloux: Metall. Trans., 1974, vol. 5, pp. 723–31.

S. Chiou and R.P. Wei: Report No. NADC-83126-60-Vol. V, Naval Air Development Center, Warminster, PA, 1984.

P.J. Bania and D. Eylon: Metall. Trans. A, 1978, vol. 9A, pp. 847–55.

M. Gao, P.S. Pao, and R.P. Wei: Metall. Trans. A, 1988, vol. 19A, pp. 1739–50.

U. Muralidharan and R. Furquen: in Advances in Mechanical Behavior and Properties, A. Saigal and A.A. Tseng, eds., ASME, Fairfield, NJ, 1988, pp. 31–38.

R. Gnanamoorthy, Y. Mutoh, K. Hayashi, and Y. Mizuhara: Scripta Metall. Mater., 1995, vol. 33, pp. 907–12.

W.O. Soboyejo: Metall. Trans. A, 1992, vol. 23A, pp. 1737–50.

S. Suresh: Metall. Trans. A, 1985, vol. 16A, pp. 249–60.

K.T. Venkateswara Rao, W. Yu, and R.O. Ritchie: Metall. Trans. A, 1988, vol. 19A, pp. 549–61.

B. Cotterell and J.R. Rice: Int. J. Fract., 1980, vol. 16, pp. 155–69.

L.R.F. Rose: Int. J. Fracture, 1986, vol. 31, pp. 233–42.

R.O. Ritchie: Mater. Sci. Eng., 1988, vol. A103, pp. 15–28.

K.S. Ravichandran and E.S. Dwarakadasa: Scripta Metall., 1989, vol. 23, pp. 1685–90.

R.K. Steele and A.J. McEvily: Eng. Fracture Mech., 1976, vol. 8, pp. 31–37.

V.K. Saxena and V.M. Radhakrishnan: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 245–61.

R.J.H. Wanhill: Br. Corr. J., 1975, vol. 10 (2), pp. 69–78.

D.N. Fager and W.F. Spurr: Trans. ASM, 1968, vol. 61, pp. 283–92.

H.J. Roven, M.A. Langøy, and E. Nes: in Fatigue-87, R.O. Ritchie and E.A. Starke, eds., Engineering Advisory Services, Warley, United Kingdom, 1987, vol. 1, pp. 175–84.

T.M. Breunig, S.R. Stock, S.D. Antolovich, J.H. Kinney, W.N. Massey, and M.C. Nichols: in Fracture Mechanics: Twenty-Second Symposium, ASTM STP 1131, H.A. Ernst, A. Saxena, and D.L. McDowell, eds., ASTM, Philadelphia, PA, 1992, vol. 1, pp. 749–61.

T.M. Breunig, S.R. Stock, and R.C. Brown: Mater. Eval., 1993, vol. 51, pp. 596–600.

A. Guvenilir, S.R. Stock, M.D. Barker, and R.A. Betz: in Aluminum Alloys: Their Physical Properties and Mechanical Properties, Vol. II, T.H. Sanders and E.A. Starke, eds., Georgia Inst. of Technology, Atlanta, GA, 1994, vol. II, pp. 413–19.

A. Guvenilir, T.M. Breunig, J.H. Kinney, and S.R. Stock: Acta Mater., 1997, vol. 45, pp. 1977–87.

A. Guvenilir and S.R. Stock: Fatigue Fract. Eng. Mater. Struct., 1998, vol. 21, pp. 439–50.

A. Guvenilir, T.M. Breunig, J.H. Kinney, and S.R. Stock: Phil. Trans. R. Soc. (London), 1999, vol. 357, pp. 2755–75.

S.R. Stock: Int. Mater. Rev., 1999, vol. 44, pp. 141–64.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stock, S.R., Langøy, M.A. Fatigue-crack growth in Ti-6Al-4V-0.1Ru in air and seawater: Part II. crack path and microstructure. Metall Mater Trans A 32, 2315–2324 (2001). https://doi.org/10.1007/s11661-001-0205-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0205-8