Abstract

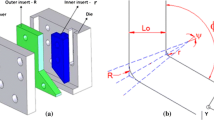

Experimental studies and finite element analysis of equal-channel angular pressing (ECAP) were carried out to clarify the deformation behavior in a sharp corner die and a round corner die under the condition without a frictional effect. It was found in both the experiment and the finite element simulation that the geometry of the die itself has a great influence on the homogeneity in deformation, resulting in more uniform shear deformation in the sharp corner die than in the round corner die under the condition without friction. The shear deformation was concentrated homogeneously on the diagonal plane of the sharp corner, which was in good agreement with the postulation of the conventional theory. In the case of the round corner die, however, plastic deformation was spread over a wide sector of the corner where shear deformation was confined to the inner part, and nonshear deformation was found in the outer part. The inhomogeneous deformation of the round corner die due to geometrical effects exhibited forward-curved flow in the outer part of the corner differently from backward-curved flow caused by frictional effects. The numerical analysis showed that more inhomogeneous distribution of stress was generated on the inlet cross section of the round corner, resulting in a variation of the normal stress from a compressive stress in the inner part to a tensile stress in the outer part. Tension followed by compression was a dominant deformation mode of the material during passing through the outer corner, and a gradual bending of the material occurred instead of shear deformation.

Similar content being viewed by others

References

V.M. Segal: Mater. Sci. Eng., 1995, vol. A197, pp. 157–64.

Z.Y. Liu, G.X. Liang, E.D. Wang, and Z.R. Wang: Mater. Sci. Eng., 1998, vol. A242, pp. 137–40.

M. Furukawa, Z. Horita, M. Nemoto, R.Z. Valiev, and T.G. Langdon: Acta Mater., 1996, vol. 44 (11), pp. 4619–29.

M. Nemoto, Z. Horita, M. Furukawa, and T.G. Langdon: Met. Mater., 1998, vol. 4 (6), pp. 1181–90.

Q. Cui and K. Ohori: J. Jpn. Inst. Light Met., 1999, vol. 49 (4), pp. 155–60.

M.A. Gibbs, K.T. Hartwig, L.G. Cornwell, R.E. Goforth, and E.A. Payzant: Scripta Mater., 1998, vol. 39 (12), pp. 1699–1704.

R.Z. Valiev, N.A. Krasilnikov, and N.K. Tsenev: Mater. Sci. Eng., 1991, vol. A137, pp. 35–40.

U. Chakkingal, A.B. Suriadi, and P.F. Thomson: Scripta Mater., 1998, vol. 39 (6), pp. 677–84.

J.C. Lee, H.K. Seok, J.H. Han, and Y.H. Chung: Mater. Res. Bull., 2001, vol. 36 (6), pp. 997–1004.

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon: Scripta Mater., 1996, vol. 35 (2), pp. 143–46.

V.M. Segal, V.I. Reznikov, A.E. Drobyshevskiy, and V.I. Kopylov: Russ. Metall. (Metally) 1981, vol. 1, pp. 99–105.

P.B. Prangnell, C. Harris, and S.M. Roberts: Scripta Mater., 1997, vol. 37 (7), pp. 983–89.

V.M. Segal: Mater. Sci. Eng., 1999, vol. A271, pp. 322–33.

J.R. Bown, A. Gholinia, S.M. Roberts, and P.B. Prangnell: Mater. Sci. Eng., 2000, vol. A287, pp. 87–99.

D.P. Delo and S.L. Semiatin: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1391–1402.

J.Y. Seo, H.S. Kim, J.W. Park, and J.Y. Chang: Scripta Mater., 2001, vol. 44 (4), pp. 677–81.

A. Shan, I.G. Moon, H.S. Ko, and J.W. Park: Scripta Mater., 1999, vol. 41 (4), pp. 353–57.

Y. Wu and I. Baker: Scripta Mater., 1997, vol. 37 (4), pp. 437–42.

Z.Y. Liu, Z. Wang, and E. Wang: Mater. Sci. Eng., 1999, vol. A262, pp. 137–40.

W.S. Hosford: Metal Forming Mechanics and Metallurgy, Prentice-Hall, Inc., Englewood Cliffs, CA, 1983, pp. 250–55.

V.M. Segal: Mater. Sci. Eng., 2000, vol. A271, pp. 322–33.

H.S. Kim, M.H. Seo, and S.I. Hong: Mater. Sci. Eng., 2000, vol.A291, pp. 86–90.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Park, JW., Suh, JY. Effect of die shape on the deformation behavior in equal-channel angular pressing. Metall Mater Trans A 32, 3007–3014 (2001). https://doi.org/10.1007/s11661-001-0175-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0175-x