Abstract

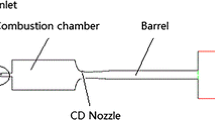

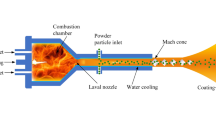

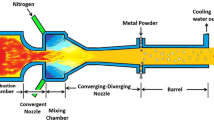

A mathematical model is formulated to simulate the effect of operational parameters on the gas dynamics that occur during high-velocity oxygen fuel (HVOF) thermal spraying. Computational fluid dynamic techniques are implemented to solve the Favre-averaged mass, momentum, and energy conservation equations. The renormalization group (RNG) κ-ɛ turbulence model is used to account for the effect of turbulence, and high-order interpolation schemes are employed to resolve compressibility effects in the supersonic jets. The calculated results show that the most sensitive parameters affecting the process are propylene flow rate, total flow rate of oxygen and propylene (oxyfuel flow rate), total inlet gas flow rate, and barrel length. The results show that increasing the total inlet gas flow rate has limited effect on the gas velocity and temperature inside the nozzle for the parameter range investigated in the present study. However, increasing the total inlet gas flow rate increases the total thermal inertia and momentum inertia; moreover, under these conditions the flame gas is retained at a high velocity and temperature for a longer distance. Increasing the oxyfuel flow rate significantly increases flame velocity and temperature, particularly after exiting the nozzle. The effect of propylene flow rate is significant and complex. In order to minimize the extent of the oxidation of the sprayed powder particles and to achieve a high flame temperature and velocity, the overall injected stream should be adjusted to be propylene-rich. The nitrogen flow rate significantly affects the gas flow inside the gun. On the basis of the calculated results, it is evident that, in order to obtain maximum gas velocity and temperature, the nitrogen flow rate should be kept to a minimum, provided that particles can be delivered to the gun in a smooth manner. By minimizing the entrainment of the surrounding air, a nozzle with a longer barrel length achieves a relatively high gas velocity and temperature for a longer distance than does a nozzle with a shorter barrel length. The calculated results are in good agreement with available experimental results.

Similar content being viewed by others

Abbreviations

- f :

-

the mass fractions of fuel and oxidant

- H :

-

total enthalpy of gas (J/kg)

- h i :

-

enthalpy for species i (J/kg)

- J ij :

-

total diffusive mass flux (kg/m2 s)

- k :

-

conductivity of gas (W/m K)

- M:

-

Mach number

- p :

-

static pressure (Pa)

- Pr:

-

gas Prandtl number, defined as µc g /k

- S a :

-

additional sources (J/s)

- T :

-

temperature of flame gas (K)

- V :

-

velocity of the flame gas (m/s)

- ρ :

-

gas density (kg/m3)

- u j :

-

jth Cartesian component of the instantaneous

- μ :

-

viscosity coefficient of gas (N s/m2)

- δ ij :

-

Kronecker delta

References

D.W. Parker and G.L. Kutner: Adv. Mater. Processing, 1991, vol. 140, p. 68.

B.H. Kear and P.R. Strutt: Nav. Res. Rev., 1995, vol. 4, p. 4.

V.L. Tellkamp, M.L. Lau, A. Fabel, and E.J. Lavernia: Nanostr. Mater., 1997, vol. 9, p. 489.

B.H. Kear and G. Skandan: Nanostr. Mater., 1996, vol. 7, p. 913.

H.G. Jiang, M.L. Lau, and E.J. Lavernia: Nanostr. Mater., 1998, vol. 10, p. 169.

M.L. Lau, V.V. Gupta, and E.J. Lavernia: Proc. Nano ’98 Conf.: 4th Int. Conf. on Nanostructure Materials, Stockholm, Sweden, June 14–19, 1998.

M.L. Lau, V.V. Gupta, and E.J. Lavernia: Nanostr. Mater., 1998, vol. 10, p. 715.

E.J. Lavernia, M.L. Lau, and H.G. Jiang: Paper presented at NATO ASI Conf., St. Petersburg, Russia, 1997.

M.L. Lau, H.G. Jiang, W. Nuchter, and E.J. Lavernia: Solidi Status Physica, 1998, p. 257.

T.S. Srivatsan and E.J. Lavernia: J. Mater. Sci., 1992, vol. 27, p. 5965.

D. Apelian, D. Wei, and B. Farouk: Metall. Trans. B, 1989, vol. 20B, pp. 251–62.

K.A. Kowalsky, D.R. Marantz, M.F. Smith, and W.L. Oberkampf: Proc. 3rd National Thermal Spray Conf., Long Beach, CA, May 20–25, 1990, ASM International, Materials Park, OH, 1991, pp. 587–92.

H.K. Kim, B.L. Choi, and S.H. Hong: Proc. ITSC ’95, 1995, May, pp. 435–40.

S. Fantassl, M. Vardelle, P. Fauchais, and C. Moreau: Proc. ITSC ’92, 1992, May, pp. 755–60.

J.R. Fincke and W.D. Swank: Proc. 3rd NTSC ’90, 1990, May, pp. 39–43.

S. Oki, S. Gohda, and K. Furukubo: Proc. ITSC ’95, 1995, May, pp. 39–43.

W.D. Swank, J.R. Fincke, D.C. Haggard, and G. Irons: Proc. 7th National Thermal Spray Conf., Boston, MA, June 20–24, 1994, ASM International, Materials Park, OH, 1994, pp. 313–18.

W.L. Oberkampf and M. Talpallikar: J. Thermal Spray Technol., 1996, vol. 5, pp. 53–68.

B. Hassan, A.R. Lopez, and W.L. Oberkampf: J. Thermal Spray Technol., 1998, vol. 7, pp. 71–77.

S. Eidelman, X. Yang, I. Lottati, and W. Grossmann: Proc. 8th National Thermal Spray Conf., Houston, TX, Sept. 11–15, 1995, ASM International, Materials Park, OH, 1995, pp. 219–24.

C.H. Chang and R.L. Moore: J. Thermal Spray Technol., 1995, vol. 4, pp. 358–66.

X. Yang and S. Eidelman: J. Thermal Spray Technol., 1996, vol. 5, pp. 175–84.

V.V. Sobolev, J.M. Guilemany, J.C. Garmier, and J.A. Calero: Surf Coating Technol., 1994, vol. 63, pp. 181–87.

Frank M. White: Fluid Mechanics, McGraw-Hill Book Company, New York, NY, 1979.

Philip A. Thompson: Compressible-Fluid Dynamics, McGraw-Hill Book Company, New York, NY, 1972.

Ali G. Cambel: Gas Dynamics, Dover Publications, Inc., New York, NY, 1968.

W.L. Oberkampf and M. Talpallikar: Proc. 7th National Thermal Spray Conf., Boston, MA, June 20–24, 1994, pp. 381–92.

S. Gordon and B.J. McBride: “Computer Program for Calculation of Complex Chemical Equilibrium Compositions, Rocket Performance, Incident and Reflected Shocks, and Chapman-Jonquet Detonations,” NASA SP-273, 1976, new version 1989.

J.M. Seiner and T.D. Norum: AIAA 12th Fluid and Plasma Dynamics Conf., Williamsburg, VA, July 23–25, 1979, AIAA, New York, NY, 1979, p. A79–47341.

C.M. Hackett, G.S. Settles, and J.D. Miller: J. Thermal Spray Technol., 1994, vol. 3, p. 299.

C.D. Donaldson and R.S. Snedeker: J. Fluid Mech., 1971, vol. 45 (2), pp. 281–319.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cheng, D., Xu, Q., Tapaga, G. et al. A numerical study of high-velocity oxygen fuel thermal spraying process. Part I: Gas phase dynamics. Metall Mater Trans A 32, 1609–1620 (2001). https://doi.org/10.1007/s11661-001-0139-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0139-1