Abstract

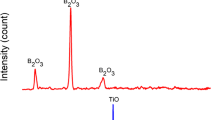

Titanium diboride (TiB2) is a very attractive material for the aluminum industry, because it is readily wetted by molten aluminum and combines good physical properties (electrical conductivity), chemical (fairly resistant to dissolution by molten aluminum), and mechanical (wear resistance) properties. In this article, both raw materials (anthracite, pitch, and TiB2 powder) and TiB2-carbon composites (TCC) were characterized. Inclusions of aluminosilicate and iron oxide types were found in the anthracite aggregates. X-ray diffraction (XRD) analysis allowed differentiation between two types of aggregates: stratified (L c=44 nm) and nonstratified (L c=15 nm). The principal impurity found in the TiB2 powder was TiCN and surface analysis of the particles revealed the presence of a contaminant layer composed of C, N, O, and Ti; the thickness of this layer varied from 5 to 15 nm. Characterization of the TiB2 particles in the composite showed important surface modifications compared to their initial state. Evidence seen on the particles’ surfaces showed that a TiC-(Otraces) formed preferentially on the side of the particles rather than on the top surface. The thickness of this TiC-(Otraces) layer was evaluated to 30 nm.

Similar content being viewed by others

References

C.E. Ransley: British Patent 784.695, British Aluminium Company, 1957.

M. Olsson, L. Kalhman, and B. Nyberg: Am. Ceramic Soc. Bull., 1995, vol. 74, (2), pp. 48–52.

D.R. Flinn: Report of Investigation 8537, Bureau of Mines, United States Department of the Interior, Washington, DC, 1981.

C. Mroz: Am. Ceram. Soc. Bull., 1993, vol. 72 (2), p. 120.

P.V. Ananthapadmanabhan, K.P. Sreekumar, P.V. Ravindran, and N. Venkatramani: J. Am. Ceram., 1993, vol. 22, pp. 1655–58.

M. Rahman, C.W. Ching, W. Chen, and S.A. Akbar: Comm. Am. Ceram. Soc., 1995, vol. 78, (5), pp. 1380–83.

F.H. Hayes and H.L. Lukas: J. Phase Equilibria, 1991, vol. 12 (5), pp. 609–11.

E.W. Dewing: Metall. Trans. A, 1989, vol. 20A, pp. 2185–87.

S.K. Rhee: J. Am. Ceram. Soc., 1970, vol. 53 (7), pp. 386–89.

K.D. Watson and J.M. Toguri: Metall. Trans. B, 1991, vol. 22B, pp. 617–21.

J. Xue and H.A. Øye: Light Met. Proc., 1993, pp. 631–37.

W.E. Haupin: Light Met. Proc., 1995, pp. 195–203.

K. Grjotheim and B.J. Welch: Aluminum Smelter Technology, 1st ed., Aluminum-Verlag GmbH, Dusseldorf, 1980, p. 8.

K. Grjotheim, C. Krohn, M. Malinovsky, K. Matiasovsky, and J. Thonstad: Aluminum Electrolysis, 2nd ed., Aluminum Verlag GmbH, Düsseldorf, 1982, pp. 289–90.

H. Zhang, V. De Nora, and J.A. Sekhar: Materials Used in the Hall-Heroult Cell for Aluminum Production, 1st ed., TMS, Warrendale, PA, 1994, pp. 47–52.

M. Dionne, G. L’Espérance, and A.A. Mirchi: Light Met. Proc., 1999, pp. 389–94.

S. Takeyasu, F. Tomoyuki, M. Hideaki, K. Katsuki, and M. Shigeharu: J. Mater. Sci., 1997, vol. 32, pp. 3933–38.

R.L. Johnson: Am. Ceram. Soc. Bull., 1995, vol. 74, (6), p. 158.

M. Dionne: Ph.D. Thesis, École Polytechnique de Montréal, Montréal.

M. Dionne, G. L’Espérance, and C. Blais: Microscopy and Analysis, 2000, November, issue 45, p. 11.

A.D. Pelton, C.W. Bale, and P. Chartrand: Facility for the Analysis of Chemical Thermodynamics (F*A*C*T), Centre for Research in Computational Thermochemistry (CRCT), Ecole Polytechnique of Montreal, Montreal, 1999.

N.R. Tuner: Light Met. Proc., 1995, pp. 573–82.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dionne, M., Mirchi, A. & L’Espérance, G. Microscopic characterization of a TiB2-Carbon material composite: Raw materials and composite characterization. Metall Mater Trans A 32, 2649–2656 (2001). https://doi.org/10.1007/s11661-001-0055-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0055-4