Abstract

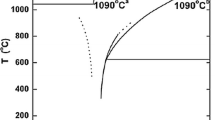

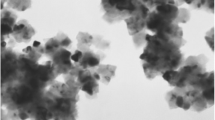

Solid state sintering behavior of nanocrystalline (35 nm) γ-Ni-Fe powders, which were sintered under hydrogen atmospheres at temperatures up to 1300 K, was investigated by laser-photo-dilatometry. The sinterability of the γ-Ni-Fe powders was found to depend crucially on the state of agglomeration and was generally limited to about 80 pct theoretical density. Metallographic observations revealed that the nanocrystalline powders showed a high degree of agglomeration which resulted in a difficult-to-sinter bimodal pore distribution. Although nanoscale intraagglomerate porosity was easily eliminated in the course of sintering, microscale interagglomerate porosity largely proved to resist densification. Experimentally observed shrinkage rates exhibit two densification maxima at the onset and the end of densification. No significant grain growth was observed during sintering.

Similar content being viewed by others

References

C. Suryanarayana: Int. Mater. Rev., 1995, vol. 40, pp. 41–64.

J.R. Groza and R.J. Dowding: Nanostr. Mater., 1996, vol. 7, pp. 749–68.

R.M. German: in Sintering Theory and Practice, R.M. German, ed., John Wiley and Sons, Oxford, United Kingdom, 1996, p. 158ff.

J.S. Lee, T.H. Kim, J.H. Yu, and S.W. Chung: Nanostr. Mater., 1997, vol. 9, pp. 153–56.

C. Cheung, F. Djuanda, U. Erb, and G. Palumbo: Nanostr. Mater., 1995, vol. 5, pp. 513–23.

S. Eroglu, S.C. Zhang, and G.L. Messing: J. Mater. Res., 1996, vol. 11, pp. 2131–34.

V. Hays, R. Marchand, G. Saindrenan, and E. Gaffet: Nanostr. Mater., 1996, vol. 7, pp. 411–20.

F. Ge, L. Chen, W. Ku, and J. Zhu: Nanostr. Mater., 1997, vol. 8, pp. 703–09.

S. Brunauer, P. Emmett, and E. Teller: J. Am. Cer. Soc., 1938, vol. 60, pp. 309–19.

G.K. Williamson and W.H. Hall: Acta Metall., 1953, vol. 1, pp. 22–31.

R.M. German: Int. J. Powder Metall., 1996, vol. 32, pp. 365–73.

O. Dominguez and J. Bigot: Nanostr. Mater., 1995, vol. 6, pp. 877–80.

D.L. Bourell and W.A. Kaysser: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 677–84.

Y.H. Zhou, M. Harmelin, and J. Bigot: Mater. Sci. Eng., 1991, vol. A133, pp. 775–79.

X.Y. Qin, J.S. Lee, and J.G. Kim: J. Appl. Phys., 1999, vol. 86, pp. 2146–54.

D. Uskokovic, J. Petkovic, and M.M. Ristic: J. Sci. Sintering, 1976, vol. 8, p. 129ff.

B. Million, J. Ruzickova, J. Velisek, and J. Vrestal: Mater. Sci. Eng., 1981, vol. 50, p. 43ff.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Knorr, P., Nam, J.G. & Lee, J.S. Sintering behavior of nanocrystalline γ-Ni-Fe powders. Metall Mater Trans A 31, 503–510 (2000). https://doi.org/10.1007/s11661-000-0286-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0286-9