Abstract

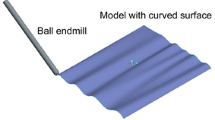

In this paper, a vibration motion control is proposed and implemented on a foamed polystyrene machining robot to suppress the generation of undesirable cusp marks, and the basic performance of the controller is verified through machining experiments of foamed polystyrene. Then, a 3 dimensional (3D) printer-like data interface is proposed for the machining robot. The 3D data interface enables to control the machining robot directly using stereolithography (STL) data without conducting any computer-aided manufacturing (CAM) process. This is done by developing a robotic preprocessor that helps to remove the need for the conventional CAM process by directly converting the STL data into cutter location source data called cutter location (CL) or cutter location source (CLS) data. The STL is a file format proposed by 3D systems, and recently is supported by many computer aided design (CAD)/CAM softwares. The STL is widely used for rapid prototyping with a 3D printer which is a typical additive manufacturing system. The STL deals with a triangular representation of a curved surface geometry. The developed 3D printer-like data interface allows to directly control the machining robot through a zigzag path, rectangular spiral path and circular spiral path generated according to the information included in STL data. The effectiveness and usefulness of the developed system are demonstrated through actual machining experiments.

Similar content being viewed by others

References

H. Zhang, J. J. Wang, G. Zhang, Z. X. Gan, Z. X. Pan, H. L. Cui, Z. Q. Zhu. Machining with flexible manipulator: Toward improving robotic machining performance. In Proceedings of IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Monterey, USA, pp. 1127–1132, 2005. DOI: 10.1109.ATM.2005.1511161.

Z. X. Pan, H. Zhang. Robotic machining from programming to process control. In Proceedings of the 7th World Congress on Intelligent Control and Automation, Chongqing, China, pp. 553–558, 2008. DOI: 10.1109/WCICA.2008.4594434.

Y. Chen, F. Dong. Robot machining: Recent development and future research issues. The International Journal of Advanced Manufacturing Technology, vol. 66, no. 9–12, pp. 1489–497, 2013. DOI: 10.1D07/S00170-012-4433-4.

G. Schreck, D. Surdilovic, J. Krueger. HEPHESTOS: Hard material small-batch industrial machining robot. In Proceedings of the 41st International Symposium on Robotics, Munich, Germany, pp. 239–244, 2014.

J. Bauer, M. Friedmann, T. Hemker, M. Pischan, C. Reinl, E. Abele, O. von Stryk. Analysis of industrial robot structure and milling process interaction for path manipulation. Process Machine Interactions, Denkena B, Hollmann F, Ed., Berlin Heidelberg, Germany: Springer, pp. 245–263, 2013.

R. Saravanan, S. Ramabalan, C. Balamurugan, A. Subash. Evolutionary trajectory planning for an industrial robot. International Journal of Automation and Computing, vol. 7, no. 2, pp. 190–198, 2010. DOI: 10.1007/s11633-010-0190-8.

T. Mikolajczyk. Manufacturing using robot. Advanced Materials Research, vol. 463–464, pp. 1643–1646, 2012. DOI: 10.4028/www.scientific.net/AMR.463-464.

A. Karim, A. Verl. Challenges and obstacles in robot-machining. In Proceedings of the 44th International Symposium on Robotics, Seoul, South Korea, 2013.

A. Puzik, C. Meyer, A. Verl. Robot machining with additional 3-D-piezo-actuation-mechanism for error compensation. In Proceedings of the 41st International Symposium on Robotics and 6th German Conference on Robotics, Munich, Germany, pp. 415–421, 2010.

F. Domroes, M. Rieger, B. Kuhlenkoetter. Towards autonomous robot machining. In Proceedings of the 41st International Symposium on Robotics, Munich, Germany, pp. 448–453, 2014.

S. Choi, C. N. Cho, H. J. Kim. Development of hexapod robot for machining. In Proceedings of the 15th International Conference on Control, Automation and Systems, Busan, South Korea, pp. 738–740, 2015.

F. Nagata, A. Otsuka, K. Nakamura, K. Watanabe. Proposal of a machining robot for foamed polystyrene materials. In Proceedings of the 2nd International Conference on Electrical, Control and Computer Engineering, Pahang, Malaysia, pp. 279–284, 2013.

F. Nagata, A. Otsuka, K. Watanabe, M. K. Habib. Fuzzy feed rate controller for a machining robot. In Proceedings of IEEE International Conference on Mechatronics and Automation, Tianjin, China, pp. 198–203, 2014.

F. Nagata, S. Yoshitake, A. Otsuka, K. Watanabe, M. K. Habib. Development of CAM system based on industrial robotic servo controller without using robot language. Robotics and Computer-integrated Manufacturing, vol. 29, no. 2, pp. 454–462, 2013. DOI: 10.1016/j.rcim.2012.09.015.

E. S. A. Nasr, A. Al-Ahmari, K. Moiduddin. CAD issues in additive manufacturing. Comprehensive Materials Processing, Hashmi S., Ed., Amsterdam: Elsevier, pp. 375–399, 2014.

A. K. Matta, D. R. Raju, K. N. S. Suman. The integration of CAD/CAM and rapid prototyping in product development: A review. Materials Today: Proceedings, vol. 2, no. 4–5, pp. 3438–3445, 2015. DOI: 10.1016/j.matpr.2015.07.319.

F. Nagata, S. Hayashi, T. Nagatomi, A. Otsuka, K. Watanabe, M. K. Habib. Robotic trajectory following controller with a capability for generating micro vibrational motion along curved surface. In Proceedings of the 41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, pp. 765–770, 2015.

W. Aribowo, K. Terashima. An implementation of cubic spline optimization with floating via points and vibration suppression for trajectory planning of industrial robot arm. In Proceedings of SICE Annual Conference, Nagoya, Japan, pp. 288–293, 2013.

A. C. Brown, D. de Beer. Development of a stereolithography (STL) slicing and G-code generation algorithm for an entry level 3-D printer. In Proceedings of IEEE African Conference, Pointe-Aux-Piments, Mauritius, pp. 1–5, 2013.

M. Szilvsi-Nagy, G. Mátyási. Analysis of STL files. Mathematical and Computer Modeling, vol. 38, no. 7–9, pp. 945–960, 2003. DOI: 10.1016/S0895-7177(03)90079-3.

C. Iancu, D. Iancu, A. Stancioiu. From CAD model to 3D print via “STL” file format. Fiabilitate si Durabilitate, vol. 1, no. 5, pp. 73–80, 2010.

Q. Wu, W. Zou, D. Xu. Viewpoint planning for freeform surface inspection using plane structured light scanners. International Journal of Automation and Computing, vol. 13, no. 1, pp. 42–52, 2016. DOI: 10.1007/s11633-015-0916-8.

F. Nagata, S. Yoshimoto, K. Kiguchi, K. Watanabe, M. K. Habib. Design of 3D printer-like data interface for a robotic removable machining. Intelligent Robotics and Applications, Kubota N., Kiguchi K., Liu H., Obo T., Eds., Cham: Springer, vol. 9834, pp. 40–50, 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the Japam Society for the Promotion of Science (JSPS) KAKENHI (Nos. 25420232 and 16K06203)

Recommended by Associate Editor Min Cheol Lee

Fusaomi Nagata received the B. Eng. degree from Department of Electronic Engineering, Kyushu Institute of Technology, Japan in 1985, and the Ph. D. degree from the Faculty of Engineering Systems and Technology at Saga University, Japan in 1999. He was a research engineer with Kyushu Matsushita Electric Corporation from 1985 to 1988, and a special researcher with Fukuoka Industrial Technology Centre from 1988 to 2006. He is currently a professor at the Department of Mechanical Engineering, Faculty of Engineering, Tokyo University of Science, Japan.

His research interests include intelligent control of industrial robot and its applications, development of network-based multiple mobile robots system and its intelligent control.

Keigo Watanabe received the B. Eng. and M. Eng. degrees in mechanical engineering from the University of Tokushima, Japan in 1976 and 1978, respectively, and the Ph. D. degree in aeronautical engineering from Kyushu University, Japan in 1984. From 1980 to 1985, he was a research associate in Kyushu University, Japan. From 1985 to 1990, he was an associate professor in the College of Engineering, Shizuoka University Japan. From April 1990 to March 1993, he was an associate professor, and from April 1993 to March 1998, he was a full professor in the Department of Mechanical Engineering at Saga University, Japan. From April 1998, he was with the Department of Advanced Systems Control Engineering, Graduate School of Science and Engineering, Saga University Japan. Currently, he is with the Department of Intelligent Mechanical Systems, Graduate School of Natural Science and Technology, Okayama University, Japan.

His research interests include intelligent signal processing and control using soft computing, bioinspired robotics, and nonholonomic systems.

Maki K. Habib received the Ph. D. degree in intelligent and autonomous robots, University of Tsukuba, Japan. He was with RIKEN Japan, RISO Laboratories, Japan, and a visiting researcher at Swiss Federal Institute of Technology in Lausanne (EPFL), Switzerland. He was a visiting expert under Asian Development Bank, associate professor at University of Technology, Malaysia, and a senior manager at Managing State-of-Art Centre for Robotics, Training and Developmemt in Industrial Automation (MCRIA), Malaysia. He was a senior research scientist with German National Research Center for information Technology (GMD), Japan, an associate professor with Monash University. Then, he was appointed as a full professor at Swinburne University. He was an invited professor at Korea Advanced Institute of Science and Technology (KAIST), Korea, and visiting professor at Saga University, Japan. He is currently a full professor at American University in Cairo, Egypt. He edited six books, and has more than 230 papers published in internationally recognized journals and conferences.

His research interests include human adaptive and friendly mechatronics, autonomous navigation, humanitarian demining, intelligent control, telecooperation, distributed teleoperation and collaborative control, wireless sensor networks and ambient intelligence, biomimetic robots

Rights and permissions

About this article

Cite this article

Nagata, F., Watanabe, K. & Habib, M.K. Machining robot with vibrational motion and 3D printer-like data interface. Int. J. Autom. Comput. 15, 1–12 (2018). https://doi.org/10.1007/s11633-017-1101-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11633-017-1101-z