Abstract

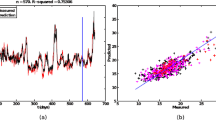

A novel soft-sensor model which incorporates PCA (principal component analysis), RBF (Radial Basis Function) networks, and MSA (Multi-scale analysis), is proposed to infer the properties of manufactured products from real process variables. PCA is carried out to select the most relevant process features and to eliminate the correlations of input variables; multi-scale analysis is introduced to acquire much more information and to reduce uncertainty in the system; and RBF networks are used to characterize the nonlinearity of the process. A prediction of the melt index (MI), or quality of polypropylene produced in an actual industrial process, is taken as a case study. Research results show that the proposed method provides promising prediction reliability and accuracy.

Similar content being viewed by others

References

G. Barto, R. S. Sutton, C. H. Anderson. Neuron-like adaptive elements that can solve difficult learning control problem. IEEE Transactions on Systems, Man, and Cybernetics, vol. 13, no. 5, 834–847, 1983.

J. G. Taylor. Towards the networks of the brain: from imaging to consciousness. Neural Networks, vol. 12, no. 7–8, pp. 943–959, 1999.

M. Basseville, A. Benveniste, K. Chou, S. Golden, R. Nikoukhah, A. Willsky. Modeling and estimation of multiresolution stochastic process. IEEE Transactions on Information Theory, vol. 38, no. 2, 766–784, 1992.

J. H. Li, J. Y. Zhang, W. Ge, X. H. Liu. Multi-scale methodology for complex systems. Chemical Engineering Science, vol. 59, no. 8–9, 1687–1700, 2004.

M. K. Gobbert, T. P. Merchant, L. J. Borucki, T. S. Cale. A multiscale simulator for low pressure chemical vapor deposition. Journal of Electrochemical Society, vol. 144, no. 11, 3945–3951, 1997.

K. J. D. Sbarbaro. Hunt, R. Zbikowski, P. J. Gawthrop. Neural networks for control systems-a survey. Automatica, vol. 28, no. 6, 1083–1112, 1992.

U. Levin, K. S. Narendra. Control of nonlinear dynamical systems using neural networks-part II: observability, identification and control. IEEE Transactions on Neural Networks, vol. 7, no. 1, 30–42, 1996.

J. Li, M. Kwauk. Exploring complex systems in chemical engineering — the multi-scale methodology. Chemical Engineering Science, vol. 58, no. 3–6, 521–535, 2003.

R. Rallo, J. Ferre-Gine, A. Arenas, F. Giralt. Neural virtual sensor for the inferential prediction of product quality from process variables. Computers and Chemical Engineering, vol. 26, no. 12, pp. 1735–1754, 2002.

J. Park, I. W. Sandberg. Universal approximation using radial basis function networks. Neural Computation, vol. 3, no. 2, pp. 246–257, 1990.

S. Mallat. A wavelet tour of signal processing. Academic Press, San Diego, 1997.

W. M. Chan, P. E. Gloor, A. E. Hamielec. Kinetic model for olefin polymerization in high-pressure autoclave reactors. AIChE Journal, vol. 39, no. 1, 111–126, 1993.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work is supported by the National Natural Science Foundation of China (No.20106008), the National Development and Reform Commission of China (No. Fagai Gaoji-2004-2080), and the science fund for distinguished young scholars of Zhejiang University (No.111000-581645).

Jian Shi received his BSc degree in Mechanical Engineering from Zhejiang University, China, in 2003. He is currently pursuing his PhD degree in the Institute of Systems Engineering of Zhejiang University. His research interests include olefin polymerization modeling, multivariate statistical process control, and neural networks.

Xing-Gao Liu received his PhD degree in Control Science and Engineering, from Zhejiang University in 2000. He was a Post Doctoral Fellow in the Automation Department, at Tsinghua University from 2000 to 2002. Currently, he is an Associate Professor in Process Systems Engineering, at the Department of Control Science and Engineering, Zhejiang University. His research interests include process modeling, control and optimization, fault detection and diagnosis, neural networks in olefin polymerization, and air separation and distillation processes.

Rights and permissions

About this article

Cite this article

Shi, J., Liu, XG. Product quality prediction by a neural soft-sensor based on MSA and PCA. Int J Automat Comput 3, 17–22 (2006). https://doi.org/10.1007/s11633-006-0017-9

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11633-006-0017-9